Applicant: ALSICO HIGH TECHNOLOGY

Inventor: SIAU GAUTHIER

Patent application number: EP4059369 (WO2022/194518)

The problem

Cleanroom coveralls usually also comprise a hood with integrated goggle. The hood may be attached to the rest of the cleanroom garment or worn with a shoulder part covered by the body part of the coverall. As such, the user becomes completely encapsulated by a relatively dense textile surface, covering the complete body of the user. At the inner side of the cleanroom coverall, a micro-climate environment is created. The temperature inside the garment may raise and the concentration of gasses like CO2 and H2O may increase gradually.

To keep the indoor atmosphere good enough for comfortable user activity, a cleanroom coverall that comprises a ventilator at the inner side of the coverall was provided by US2020/0359714.

However, this cleanroom coverall has some disadvantages. The ventilator is provided in a longitudinal hollow body, the ventilator blowing air into the coverall via the proximal open end of the longitudinal hollow body. This proximal open end of the longitudinal hollow body may be open or closed, depending on the status of a valve installed at the proximal open end of the longitudinal hollow body. Via a surrounding air suction tube, air is sucked from the coveralls ambient into the longitudinal hollow body. The surrounding air suction tube is connected to the coverall textile by an air inlet means which is situated on the outer side of the coverall. This air inlet is an open means, i.e. there is not necessarily a filter present between the coverall ambient and the inner side of the inlet, once coupled between the coverall ambient and up to the one way valve. Hence contaminants present in the passageway from the ambient, passing the ventilator up to the one-way valve may form a potential contamination when the coverall is used inside a cleanroom. This in particular if, for whatever reason, a counter airflow from the one-way valve back to the ambient is generated.

If for whatever reason the air suction tube gets disconnected from the air inlet, an open channel is created between the inner side of the cleanroom garment and the ambient of the cleanroom garment. This is a severe risk for contaminating the cleanroom atmosphere.

The solution

The invention relates to cleanroom garments, like cleanroom coveralls, and to the use of such cleanroom garments in cleanroom environments. The cleanroom coveralls have a reduced risk in contaminating the ambient of the cleanroom, while being safe and/or comfortable to wear.

The cleanroom coveralls have a well-controlled inside environment creating good and controlled working conditions for the user wearing the cleanroom coverall.

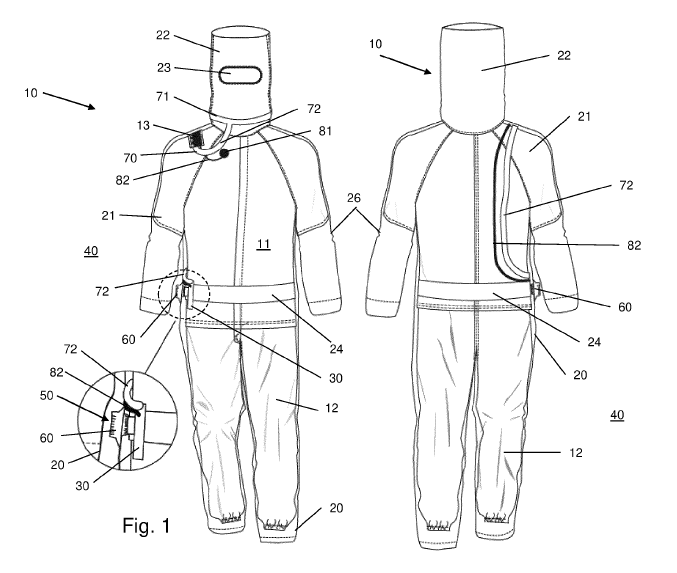

The cleanroom coverall comprises a coverall suit and a ventilator positioned inside the coverall suit. The ventilator is fluidly connected to the ambient of the cleanroom coverall, such that between the ambient of the cleanroom coverall and the ventilator, a one-way valve is present, which one-way valve opens when the ventilator is active. A one-way valve is also known as check valve, non-return valve, reflux valve, retention valve, or foot valve.

The coverall suit is provided from textile material, which textile material is adapted for use for cleanroom garment. Typically, the textile material is a relatively dense, possibly polyester (PES), filament woven fabric being provided with antistatic properties. The textile material preferably has a surface weight in the range of 40 to 220 g/m2, such as in the range of 50 to 200 g/m2. The textile material preferably meets the requirements of IEST-RP-CC003.4 and the anti-static clothing standard EN1149.

This cleanroom garment according to the first aspect of the invention has the advantage that upon interruption of the ventilator activity, upon blockage of the ventilator output or upon malfunctioning of the one-way valve, the risk on contamination flowing back to the ambient of the cleanroom coverall, is reduced or even brought to zero. As the one-way valve is situated before, upstream the ventilator, and preferably as close as possible to the coverall suit, the volume of possibly contaminated air which may flow back to the cleanroom environment, i.e. the ambient of the cleanroom coverall, is restricted.

As the one-way valve opens only upon activation of the ventilator, it means that in case of inactivity of the ventilator, either before or during use, no contaminated air can flow to the cleanroom coverall ambient. In case of a back pulse, this valve will close before the back pulse pressure has passed the valve, thus before it has had the opportunity to pass beyond the valve towards the ambient.

The one-way valve is present in the fluid guiding means present between the ambient of the coverall suit and the intake side of the valve.

Also, during use of the cleanroom coverall in the cleanroom, there is less danger to contaminate the ambient in the cleanroom in case the coupling of the coupling means to the fluid guiding means or ventilator is broken. In this situation, the one-way valve will immediately close, and the risk of contaminated air to flow back into the ambient is virtually nihil.

A cleanroom coverall comprises a coverall suit and a CO2 measurement device, also referred to as CO2 sensor, being present inside the coverall suit. Possibly, the CO2 measurement devices or "sensor", are based upon spectrometric principles, such as nondispersive IR sensors. The CO2 measurement device may be part of a measurement system, measuring, next to CO2, also the humidity, the temperature, the oxygen content, possible CO content and/or any other relevant component in the atmosphere inside the coverall suit. Optionally, more than one measurement device per measured criterion may be provided, e.g. two or more CO2 measurement devices.

Preferably the CO2 measurement device may be located near the chest of the user or near the neck of the user, such as near the upper part of the chest, e.g. near the left or right clavicle of the user or at the level of the thyroid gland of the user. This position was found to be most efficient and reliable to measure the content of the environment inside the coverall suit.

In general, the flow rate of the ventilator may at maximum be 150 l/min, such as in the range of 0l/min to 150 l/min, such as in the range of 50 l/min to 150 l/min.

The cleanroom coverall may further comprise an alarm system. The alarm system may generate an alarm signal, such as a visual, tangible and/or auditive signal, when the CO2 value measured by the CO2 measurement device exceeds one or more threshold values.

Advantages

- The one-way valve being present in the coupling means which is part of the coverall suit, has the advantage that, as long as the coupling means is not coupled to the fluid guiding means present between the ambient of the coverall suit and the intake side of the ventilator, or to the intake of the ventilator itself, there is no opening in the coverall suit itself.

- The provision of air supply from the ventilator into the hood portion of the cleanroom coverall, in particular directly near the nose, mouth and/or cheeks of the user, has as an advantage that the occurrence of steaming up the goggle, or even the creation of condensation liquid on the goggles, can be partially or completely avoided.

- This cleanroom garment according to the first aspect of the invention has the advantage that upon interruption of the ventilator activity, upon blockage of the ventilator output or upon malfunctioning of the one-way valve, the risk on contamination flowing back to the ambient of the cleanroom coverall, is reduced or even brought to zero.

- There is no open channel between the two sides of the coverall suit, which may be problematic if the cleanroom coverall is already in use in the cleanroom itself.

- The one-way valve being present in the coupling means which is part of the coverall suit, has the advantage that, as long as the coupling means is not coupled to the fluid guiding means present between the ambient of the coverall suit and the intake side of the ventilator, or to the intake of the ventilator itself, there is no opening in the coverall suit itself. This means that, from the moment the coverall suit is worn by the user, there is no opening anymore between the "dirty" side inside the coverall suit, and the clean side outside the coverall suit, independent whether or not the coupling is coupled to the fluid guiding means or the ventilator. The user can safely enter the cleanroom even with a coupling means uncoupled, because dirty side and clean side are not in communication with each other except through the cleanroom garment textile itself. There is no open channel between the two sides of the coverall suit, which may be problematic if the cleanroom coverall is already in use in the cleanroom itself. So, the coupling can be made, and this coupling will not create an open channel between the two sides of the coverall suit. And even in case the user forgets to make the coupling, there will not be an open channel between the two sides of the coverall suit. The cleanroom coverall according to the present invention hence provided certainty of use in cleanroom environment, even in case of mistake of the user.