The PlasmaSol project will develop more innovative and sustainable adhesion and functionalisation technologies for various materials through atmospheric plasma.

Context

In the past, durable adhesion on a broad range of substrates has been achieved using conventional wet chemical surface treatments. These wet chemical surface treatments come with several ecological and health – related issues. It is well-known that solvent-based technologies are hazardous and highly flammable.

However, also water-based processes, although being a safer alternative for solvent-based processes, come with ecological disadvantages. As such, a vast amount of waste water is generated, whereas the need for an additional drying step leads to a high energy consumption. Within the aim of reducing energy and (hazardous) chemical usage, atmospheric plasma technology is proposed as an eco-friendly alternative for surface activation and modification, while offering properties that are not always within the reach of conventional processes. Meanwhile, conventional process steps (i.e. cleaning steps, primer application) can be eliminated leading to reduced process time and energy- and chemical usage.

This project focuses on plasma functionalisation as a promising technology to improve adhesion, anti-bacterial and flame-retarding properties.

Actions

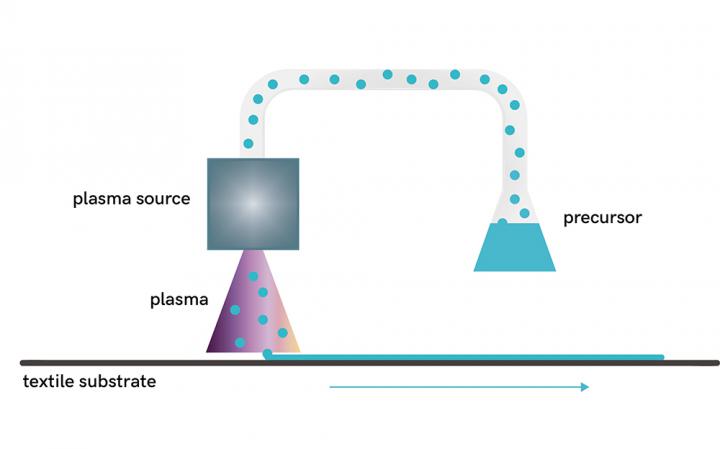

This project focuses on retrieving fundamental physical and chemical insights in plasma polymerization and modification mechanisms as well as modelling of the plasma process. Considering its applicability in industrially relevant environments, the plasma reactor design will be optimized to obtain homogeneously deposited functionalised coatings. Furthermore, efforts will be taken to automise this new technology to make it industrially viable for a broad range of applications.

Within the project Centexbel is investigating the possibilities of plasma functionalisation to confer antimicrobial, flame-retardant or fluorine free hydrophobic properties to textiles.

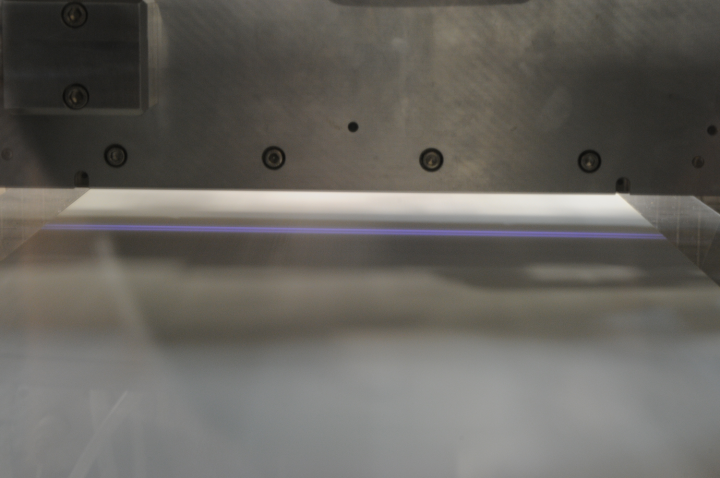

To this effect, we are using the PlasmaLine of project partner Molecular Plasma Group to gain fundamental insights and to develop chemical and physical knowledge about the plasma functionalisation of a broad range of textile substrates. The R&D plasma device is designed to treat the surface of any material in a semi-industrial setting, ensuring an easy industrial upscaling in a later stage.

By looking into the effect of several plasma process parameters such as plasma power, precursor type/concentration, treatment time, etc. on the surface properties of the treated samples, Centexbel expands its expertise in using plasma technology for the textile sector.

From Innovation to Business

With a broad range of industrial partners working together throughout the value chain and new fundamental insights and innovations in atmospheric plasma from the knowledge institutions, the PlasmaSol partners will maximize the potential to discover new industrial applications.

Project Details

| Project type: | ICON |

| Approved on: | 24/10/2019 |

| Duration: | 01/11/2019 – 31/10/2022 |

| Total budget: | €3.371.978 |

| Subsidy: | €2.325.748 |

Partners