Centexbel offers a complete portfolio for PFAS screening and analyses

Screening Fluorine

When a consumer product is screened for risk components, we start by testing for the presence of Fluorine.

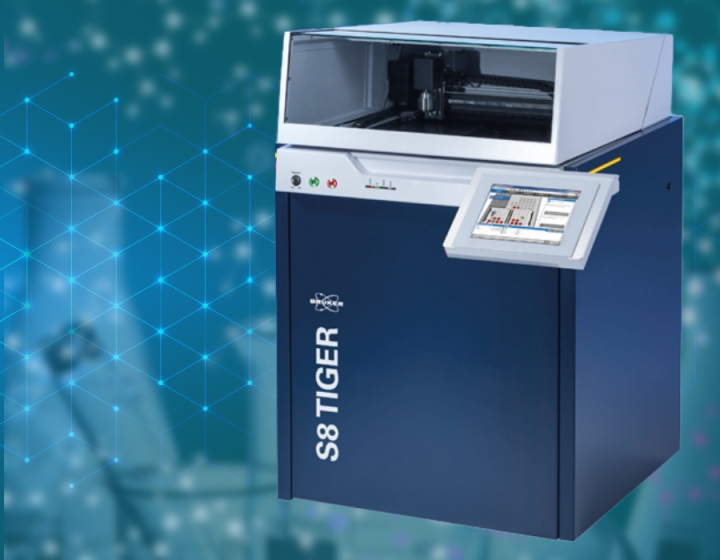

The first step is a WD-XRF analysis. High energy radiation is sent to the sample and excites the electrons in the chemical elements. When the atom relaxes, X-ray fluorescence radiation is emitted in wavelengths that are typical for each element. Fluorine in very low concentrations can be measured with this technique. This surface technique allows a quick selection of samples with fluorine presence.

A second step is analyzing fluorine using Combustion Ion Chromatography (CIC). Depending on the conditions and the pretreatment different parameters can be measured. EOF (extractable organic fluorine) will typically measure extractable organic fluorine substances (part of which are PFAS). A variant is AOF (adsorbable organic fluorine) where organic substances are adsorbed before analysis. Legislation and RSLs (restricted substances list) tend to switch to TOF (total organic fluorine) and/or TF (total fluorine). It is sometimes difficult to differentiate between PFAS and other organic fluorine substances and inorganic substances using this technique. Centexbel is carrying out research in this field.

The presence of Fluorine may indicate the presence of residual PFAS

To check whether the amount of some target PFAS is significant we perform a screening on LCMS of a general solvent extract, which will give us a decisive answer. PFOA and other PFAS are detected together with other substances, such as nonylphenol and nonylphenol ethoxylates, azodicarbonamide and UV stabilizers (REACH SVHC parameters).

Quantitative determination of PFAS

The special feature of the PFAS (e.g. PFOA) determination is that the substance is detected down to a very low limit, while the method itself involves risks of contamination. Teflon is used in the production of high-purity water, analytical standards and chemicals, as well as in the analysis equipment itself. Therefore, a distinction must be made between "background PFOA" and the PFOA from the sample itself.

PFOA, PFOS and other polar PFAS are analyzed using triple quad LCMS. In a health- risk based approach these are the most important PFAS. They are determined at very low levels and are targeted by most of the legislations and RSLs.

Centexbel offers the following test methods according to EN 17681-1 (textiles), EN 23702-1 (leather) or the OEKO-TEX® method:

- C9-C14 substances and their salts (REACH Annex XVII entry 68)

- PFOA substances and their salts, PFHxS substances and their salts & PFOS and its derivatives (POPs Regulation)

- PFHxA substances and their salts (current restriction proposal under REACH Annex XVII)

Quantitative analysis of target PFAS using triple quad GCMS

Telomer-alcohols and -acrylates are more volatile PFAS. Their level will diminish quite quick after production of consumer articles. They may however influence the air quality e.g. in large shops selling outdoor articles. As these substances are more volatile, they are typically analyzed using GCMS techniques (triple quad).

Centexbel offers the following test methods according to EN 17681-2 (textiles), EN 23702-2 (leather) or the OEKO-TEX® method:

- C9-C14 telomer-alcohols and -acrylates (REACH Annex XVII entry 68)

- PFOA telomer-alcohols and -acrylates (POP Regulation)

- PFHxA telomer-alcohols and -acrylates (current restriction proposal under REACH Annex XVI)

Identification of unknown PFAS

As techniques like CIC may lead to false positive results due to presence of other organic fluorine substances like dyestuffs an agrochemicals, it is important to be able to identify unknown fluorinated substances. This will make it possible to know if these substances are really PFAS (several thousands of PFAS exist while typical target analyses only cover 40- 60 target substances). Fluorinates substances (think about the fluoride in your toothpaste) may contain fluorine without being a forever chemical (PFAS). Centexbel hopes to be able soon to identify these unknows using high resolution LCMS (HRAM LCMS).

PFAS substances will also be targeted in USA under the California Law AB1817 (safer clothes & textile act). This is the first state in the USA that will ban PFAS substances on apparel & textile products.

The following limits will apply as from:

- 01/01/25: 100ppm total PFAS, measured via total fluorine (TF)

- 01/01/27: 50ppm total PFAS, measured via total fluorine (TF)

This will be measured via CIC. Results of this measurement can be used to compare legal limits for PFAS in the USA.

With the recent investments described above, Centexbel is now able to screen and quantitatively determine the legislative PFAS-substances in Europe (REACH & POP) and USA (AB1817).