The invention by Milliken & Co generally relates to creating magnetic scrims for easier processing for molding applications.

In some molding applications, foams such as polyurethanes are combined with other textile layers such as scrims during the molding process. The scrims can give the polyurethane additional strength and other characteristics such as fire resistance. There is a need for a scrim that is more easily inserted and positioned within the mold to reduce incorrect molding location and operator time to position the scrim.

The invention relates to a magnetically responsive scrim containing a plurality of yarns and a magnetically responsive coating covering at least a portion of the yarns of the scrim. The magnetically responsive coating contains magnetically responsive particulate material and a binder, where the magnetically responsive coating is at least about 40% by weight magnetically responsive particulate material, and where the magnetically responsive coating has an areal density of at least twice the areal density of the scrim.

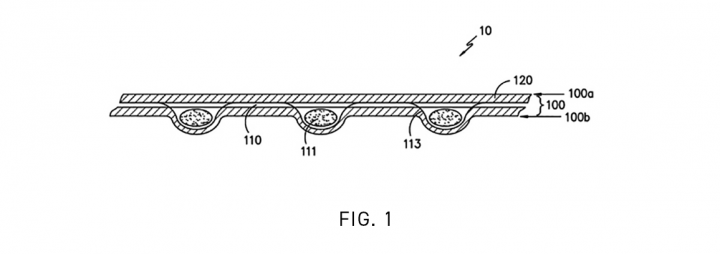

FIG. 1, there is shown one embodiment of the magnetically responsive scrim 10. The magnetically responsive scrim 10 contains a scrim 100 having a first side 100a and a second side 100b. The scrim 100 contains a plurality of yarns. The magnetically responsive scrim 10 also contains a magnetically responsive coating 120 that covers at least a portion of the yarns of the scrim 100.

This magnetically responsive scrim 10 would preferably be placed in a mold with at least one magnet to hold the scrim in place while the mold is prepared and polyurethane (or other moldable material) is introduced and then cured in the mold.

The scrim 100 may be any suitable scrim including any suitable light-weight woven, knit, or nonwoven fabric. Preferably, the scrim layer is a weft inserted warp knit scrim. A weft inserted warp knit scrim 100 contains a plurality of warp yarns 110, weft yarns 111, and stitching yarns 113. The stitching yarns 113 may have any suitable stitching pattern, including tricot stitches or pillar stitches, or other stitches. The weft yarns 111 can be laid in every course (every row of stitches from the stitching yarn), every second course (every second row of stitches from the stitching yarn), every third course (every third row of stitches from the stitching yarn) or more. How open or closed (how close together the yarns are within the scrim 100, is determined by the types and sizes of the yarns and the desired properties of the scrim 100 and magnetically response scrim

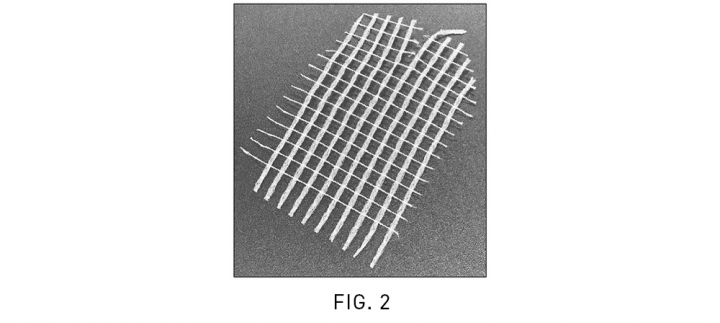

FIG 2. Some suitable materials for the yarns include polyamide, aramid (including meta and para forms), rayon, PVA (polyvinyl alcohol), polyester, polyolefin, polyvinyl, nylon (including nylon 6, nylon 6,6, and nylon 4,6), polyethylene naphthalate (PEN), cotton, steel, carbon, fiberglass, steel, polyacrylic, polytrimethylene terephthalate (PTT), polycyclohexane dimethylene terephthalate (PCT), polybutylene terephthalate (PBT), PET modified with polyethylene glycol (PEG), polylactic acid (PLA), polytrimethylene terephthalate, nylons (including nylon 6 and nylon 6,6); regenerated cellulosics (such as rayon or Tencel); elastomeric materials such as spandex; high-performance fibers such as the polyaramids, and polyimides natural fibers such as cotton, linen, ramie, and hemp, proteinaceous materials such as silk, wool, and other animal hairs such as angora, alpaca, and vicuna, fiber reinforced polymers, thermosetting polymers, blends thereof, and mixtures thereof. In a preferred embodiment, the yarns comprise polyester yarns. In another embodiment, the yarns of the magnetically response scrim 10 consist essentially of polyester yarns (defined to be mean at least 98% of the yarns are polyester yarns).

In this application “magnetically responsive” is defined to mean the particles present in the coating are only magnetically responsive in the presence of external magnets. Once the magnetic field is removed from the vicinity, the particles will become non-magnetic. The magnetically responsive behavior or responsive magnetic behavior falls broadly under paramagnets or superparamagnets (particle size less than 50 nm), or weak ferromagnets. Iron oxide, steel, iron, nickel, aluminum or their alloys that are not included in ferromagnets are some of the examples that can be applied in the coatings. In a preferred embodiment, the magnetically responsive particulate material comprises iron oxide particles, such as Fe2O3 particles and Fe3O4 particles. Iron oxide particles are generally preferred over iron particles because iron particles may rust in high humidity environments, and such rusting can discolor one or more components of the system (particle size of about 50 microns or less).