Additive Manufacturing (AM) involves a series of techniques to produce objects by adding materials layer per layer. Centexbel-VKC researches the possibilites of AM or 3D printing to functionalize and to customize conventionally produced textile and plastic objects.

To enable a widespread implementation of AM processes in the textile and plastic converting industry, Centexbel-VKC is developing appropriate filaments with customized properties, such as soft and flexible materials with conductive properties for the creation of smart textiles.

The Centexbel-VKC 3D Printing labs (in Kortrijk and Grâce-Hollogne) are also open to the industry for rapid prototyping and R&D purposes.

The Centexbel-VKC 3D platform is composed of different types of 3D printers to cover different processing procedures departing from various types of of raw material: filaments, UV curable resins and direct granulate processing.

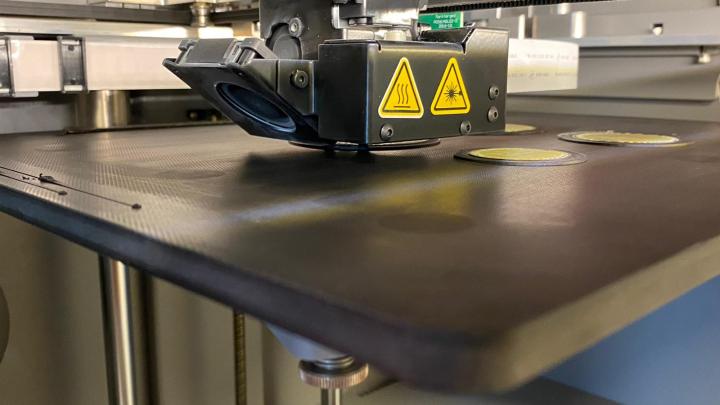

Markforged X7 for Continuous Fiber Reinforcement (CFR)

Principle of Continuous fiber fabrication (CFF):

- The 3D printer is equipped with 2 nozzles.

- The first nozzle functions as in a conventional fused filament fabrication (FFF) process depositing plastic filaments (onyx, onyx FR and Nylon white) to form the outer shell and inner matrix of the part.

- The second nozzle deposits continuous reinforcements (made from Carbon Fiber, Fiberglass, Kevlar, and HSHT Fiberglass) on each layer

More info

The X7 3D is an industrial composite 3D printer, allowing us to print continuous carbon fibre-reinforced parts with fire-resistant, chemical-resistant, energy-absorbing, high-resolution, etc. properties in just a few hours.

Dimensions

B: 584 mm

D: 483 mm

H: 914 mm

Weight: 48 kg

Volume

W: 330 mm

D: 270 mm

H: 200 mm

This industrial 3D printer is installed in Grâce-Hollogne, the other 3D printers are operational in Kortrijk.

Fused Filament Fabrication (FFF) – Ultimaker S5

Raw material:

- synthetic filaments

Principle:

FFF-based 3D-printers use a thermoplastic filament that is pushed through a heated extruder head (including one or more extrusion nozzles) using a drive wheel. The head can be driven both horizontally and vertically, creating one layer at a time before adjusting vertically to begin a new layer.

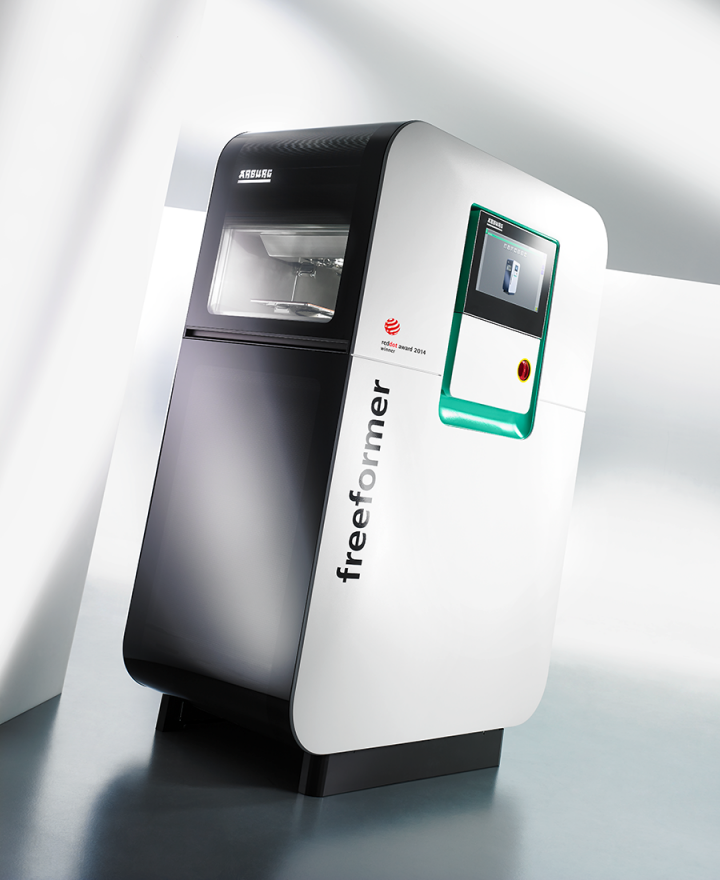

3D Freeformer Technology

Raw material

- polymer granulates

Principle

A key feature of ARBURG Plastic Freeforming (APF) is that the same qualified standard granulates as used for injection molding can be used, enabling us to produce individual parts and small batches from original materials, but also to individualize mass-produced items.

The freeformer system is equipped with a material preparation unit featuring a special plasticizing screw. Plasticizing is followed by freeforming without the use of a mould: a high frequency nozzle closure discharges tiny plastic droplets, which are applied very precisely by means of a moving part carrier. This enables three-dimensional plastic parts to be built up layer-by-layer. This is even possible with multiple-component parts.