16 April, 2024

Thermoplastic fibre-reinforced composites, known for their lightweight nature and flexibility, have become an essential component in the field of aviation and aerospace. In fact, some modern aircraft now comprise over 50% of fibre reinforced composites. However, this progress has brought about the pressing concern of recycling these composite materials.

A challenge Centexbel successfully embraced!

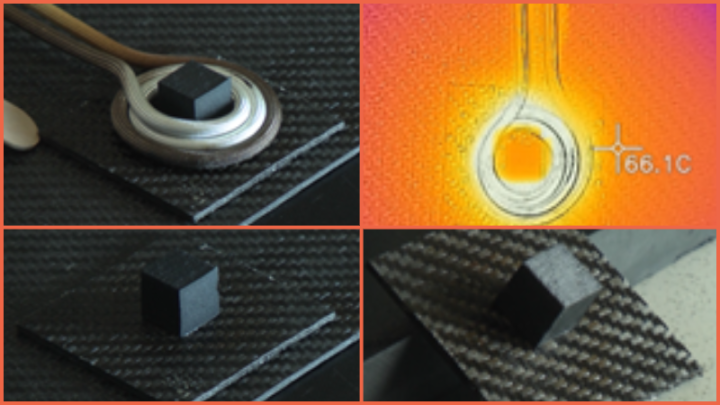

Today, we are honoured with the Techtextil Innovation Award for our development aimed at enhancing the recycling of thermoplastic fibre composites used in aircraft parts. Our innovative process, closely monitored by Airbus, incorporates the use of induction heat to effectively separate and recover thermoplastic, textile-reinforced composite materials.

As a result, the separation and reusability of crucial aircraft components like stringers, wing parts, and other textile-based elements will be significantly improved.

Myriam Vanneste, R&D manager “Textile Functionalisation & Surface Modification” at Centexbel, says:

This Techtextil Innovation Award motivates us to continue working on projects to improve sustainability in various industries such as the aerospace industry.

HELACS has received funding from the Clean Sky 2 Joint Undertaking under the European Union’s Horizon 2020 research and innovation programme under grant agreement Nº 101007871.