This month’s collection showcases the diverse range of uses for fiber reinforced plastics or composites, spanning from transportation (such as aircraft, automotive, motorcycle) to sustainable energy generation (like wind turbines) and safety applications (such as road barriers).

In addition to traditional injection/compression molding, 3D printing is emerging as a dependable technique for manufacturing composite components. While epoxy resin-based composites continue to be prevalent, alternative resins like polyphenylene sulfide, polyurethane, and polyolefin are also being explored.

Similar to other industries, the concept of circularity is a key focus in the field of composites. Particularly, the emphasis is on recycling these composite structures at the end of their lifespan and repurposing them in the production of new composite parts.

Composite profile and mixed yarn for manufacturing composite profiles

Patent number: BE1030711

Publication date: 2024-02-12

Applicant(s): SIOEN INDUSTRIES

Inventor(s): VAN DAMME JONAS FERNAND HUGUETTE; WILLE JOOST

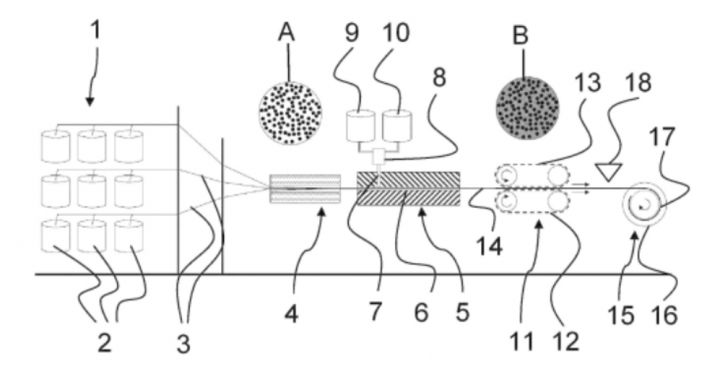

Summary

The present invention concerns mixed yarn for manufacturing composite profiles. The mixed yarn is composed of glass fiber filaments and thermoplastic filaments made from a polymer mixture of a first polyester and a second polymer different from the first polyester. The glass temperature of the polymer mixture is at least 5°C higher than the glass temperature of the first polyester. Alternatively, the blended yarn may be composed of glass fiber filaments and thermoplastic filaments made from the first polyester and thermoplastic filaments made from the second polymer. The weighted average of the glass transition temperature of the thermoplastic filaments is at least 5°C higher than the glass transition temperature of the first polyester.

Polyphenylene sulfide resin composition and molded articles for automobiles manufactured using the same

Patent number: US20240002662

Publication date: 2024-01-04

Applicant(s): HYUNDAI MOBIS CO., LTD.; HYUNDAI Advanced Materials Co., Ltd.

Inventor(s): KANG HYOUNG TAEK; LEE EUN CHANG; LEE SANG GIL; KOO KWON MO; HWANG SANG WOON; KIM DONG JU

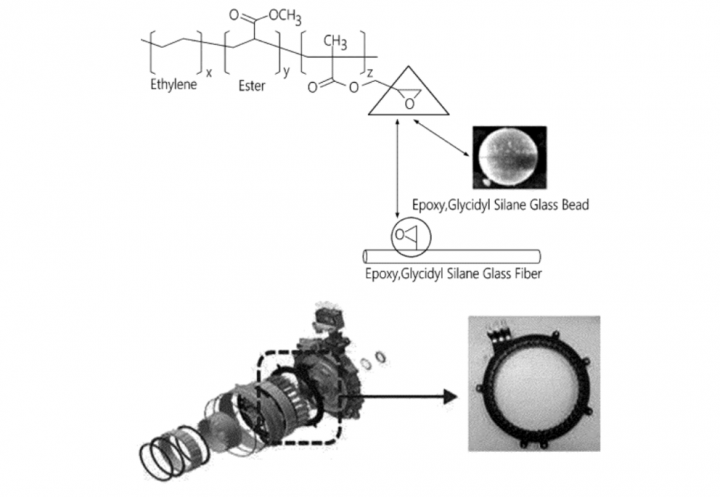

Summary

Disclosed is a polyphenylene sulfide resin composition for an automobile part that includes 30 to 40 parts by weight of a glass fiber, 10 to 20 parts by weight of glass bead, and 5 to 10 parts by weight of a polyolefin resin for each 100 parts by weight of a polyphenylene sulfide resin. The present disclosure provides a resin composition for an automobile that has an effect of improving cracks in parts due to thermal shock and high temperature aging, can secure flattened parts by preventing local shrinkage, and can prevent insulating properties from being degraded due to deterioration. The present disclosure also provides a resin composition capable of reducing the occurrence of cracks in parts and improving long-term durability of a driving motor, and a molded article for an automobile manufactured using the same. The present disclosure also provides a terminal assembly of an automobile driving motor in which low warpage properties and insulating properties are secured at the same time, thereby improving the performance of the automobile. The present disclosure also provides a resin composition for a terminal assembly of an automobile driving motor which has improved flattening properties and suppresses deterioration in insulating properties due to deterioration of the impact modifier prescribed to prevent cracks due to thermal shock.

Endless-fibre-reinforced 3d-printing filament and method for the production thereof

Patent number: DE102022115439

Publication date: 2023-12-21

Applicant(s): Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung eingetragener Verein

Inventor(s): WILHELM MICHAEL; ROSENBERG PHILIPP; HENNING FRANK

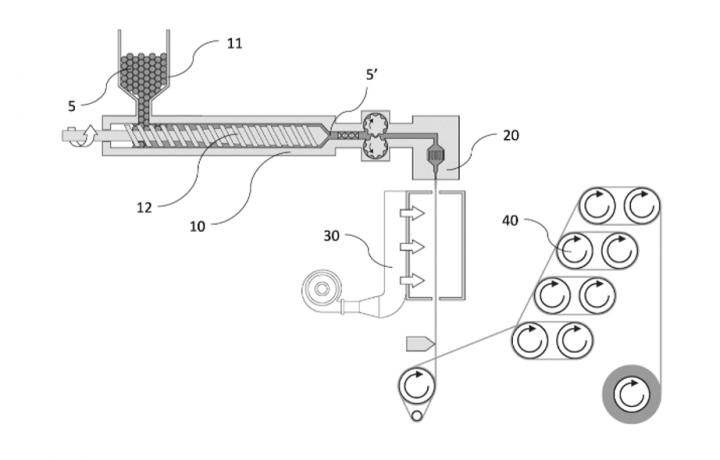

Summary

The invention relates to a method for producing continuous-fiber-reinforced 3D printing filaments comprising a thermoplastic matrix polymer with a plurality of continuous fibers extending in the longitudinal direction of the 3D printing filament. According to said method, a plurality of continuous fibers are oriented according to the arrangement thereof in the 3D printing filament and are impregnated with the thermoplastic matrix polymer. The continuous strand thus obtained is then cut into lengths to form the continuous-fiber-reinforced 3D printing filament. According to the invention, the plurality of aligned continuous fibers is impregnated with a liquid reaction mixture which contains a liquid monomer, di- and/or oligomer suitable for polymerization to form the thermoplastic matrix polymer and an initiator and/or catalyst suitable for initiating the polymerization. The monomer, di- and/or oligomer is then polymerized in situ to form the matrix polymer. The invention further relates to a continuous fiber-reinforced 3D printing filament produced in this way.

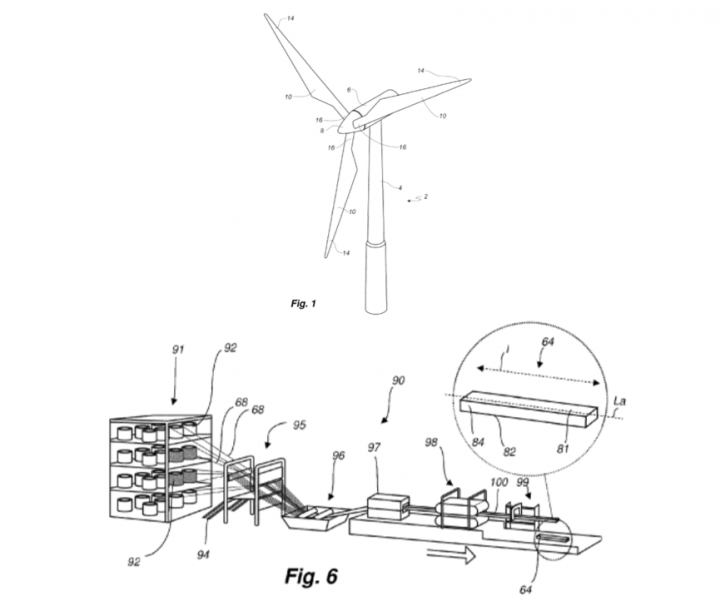

Multicomponent resin system for manufacturing pultruded wind turbine blade components

Patent number: EP4144514

Publication date: 2023-03-08

Applicant(s): LM WIND POWER AS

Inventor(s): BAVILOLIAIE MAHDI

Summary

The present invention relates to a method of manufacturing a wind turbine blade and to pultruded blade components used in said method. One or more pultruded blade components can be manufactured in a pultrusion process comprising contacting a fibre material (68) with a multicomponent resin system, and curing the multicomponent resin system to form a fibre-reinforced vinyl ester urethane composite. The pultruded blade component (64) comprising the cured vinyl ester urethane resin can be arranged within the blade shell component (38).

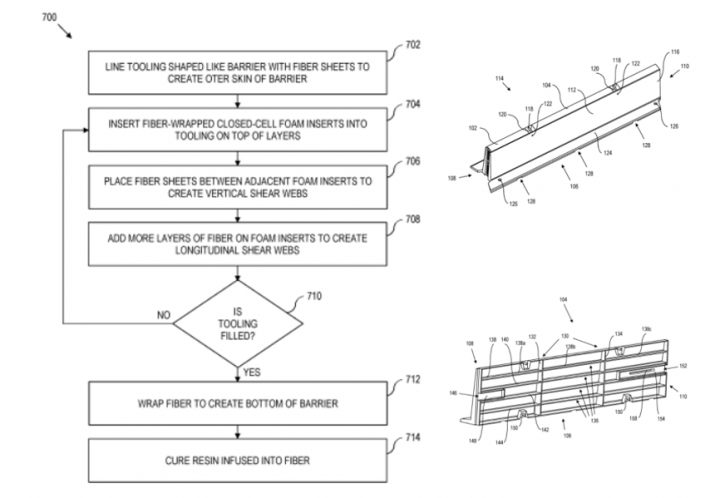

Fiber reinforced resin-based temporary road barrier

Patent number: US20230083017

Publication date: 2023-03-16

Applicant(s): ASYNT SOLUTIONS? LLC

Inventor(s): SCOTT III ARCHIE

Summary

A resin-based barrier comprises a body having a skin of fiber-reinforced resin. The body includes a top, a bottom, a front end, and a back end. A vertical shear web runs between the top and the bottom and is substantially perpendicular to the top and the bottom. Moreover, spaces between the vertical webbing and between the longitudinal webbing are filled with a high-density closed-cell foam. The barrier may be used as a temporary traffic barrier during road construction.

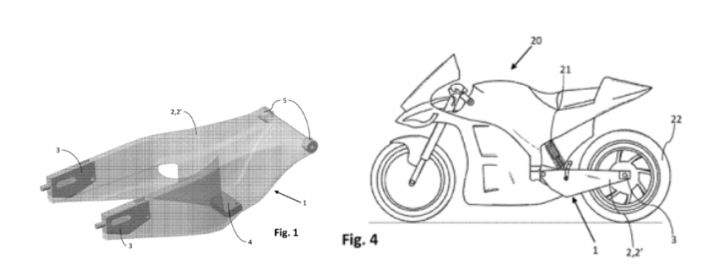

Motorcycle rear swingarm, motorcycle with swingarm and manufacturing method

Patent number: WO2023/052911

Publication date: 2023-04-06

Applicant(s): PIAGGIO & C. S.P.A.

Inventor(s): AGUGGIARO ANDREA

Summary

An assembly (1) for a motorcycle comprising: • - a first element (2) consisting of a first composite material comprising one or more fabrics of carbon fibers linked together by means of a polymeric resin; and a second element (3,4,5) consisting of a second composite material comprising chopped and randomly arranged carbon fibers linked together by means of a polymeric resin; wherein: the first element (2) is bonded to the second element (3,4,5) by means of a structural adhesive; the first element (2) is a swingarm (21) and the second element (3,4,5) is constrained to the swingarm (21) and comprises one or more of: a slider (3), a support (4) of a suspension (21) of the motorcycle, a bushing (5). The present invention further relates to a motorcycle comprising an assembly (1) as described above, and a method of manufacturing said assembly (1).

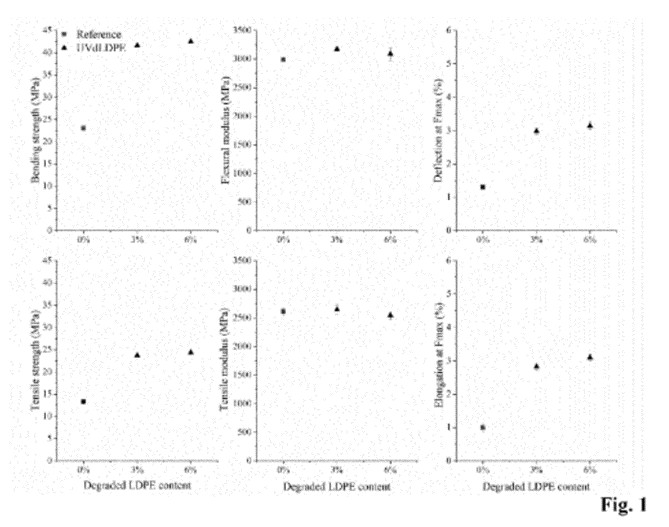

Fiber-reinforced composite material containing photodegraded polyolefin as bonding agent

Patent number: EP4223488

Publication date: 2023-08-09

Applicant(s): Universität Hamburg

Inventor(s): DE ANGELIS MARCO; SCHMIDT GORAN; KRAUSE ANDREAS

Summary

The invention relates to a fiber-reinforced composite material comprising reinforcing fibers embedded in a thermoplastic matrix, wherein the composite material comprises a bonding agent for bonding the reinforcing fibers to the thermoplastic matrix, the bonding agent being or comprising a photodegraded polyolefin. The invention relates to a fiber-reinforced composite material containing photodegraded polyolefin as bonding agent, a method of preparing the composite material, the use of a photodegraded polyolefin as a bonding agent, and an article of manufacture comprising the fiber-reinforce composite materials.