Nous sommes fiers de vous présenter une sélection de brevets déposés par Centexbel au fil des ans.

Use of a dispersion for textile coating

Patent number: EP3875545

Date of publication: 2021-09-08

Applicant: Centexbel

Inventors: DEMEDTS BRECHT, DE SMET DAVID, UYTTENDAELE WILLEM, VANNESTE MYRIAM

Abstract

Use of a dispersion for coating textiles, said dispersion comprising a powder dispersed in an aqueous medium, said powder comprising a thermoplastic biopolymer plasticized with an ethoxylated fatty acid and a plasticizer different from said ethoxylated fatty acid.

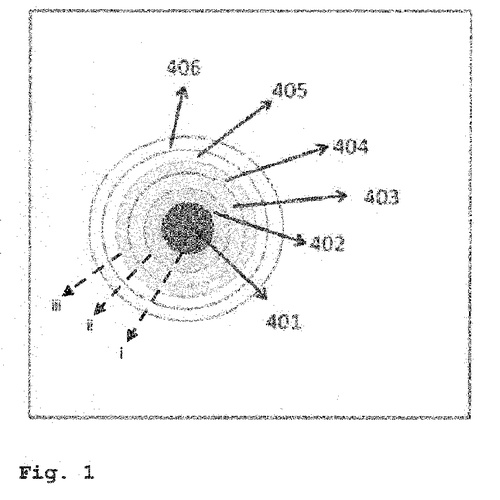

A wire shaped coaxial photovoltaic solar cell

Patent number: EP3168877

Date of publication: 2017-05-17

Applicant(s): BONAR, BRUNEL UNIVERSITY, CENTEXBEL, CENTITVC, ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE (EPFL) TTO, FUNDACIÓ EURECAT, LINDSTRAND TECHNOLOGY, OHMATEX, PEERLESS PLASTICS & COATINGS, SEFAR AG, VDS WEAVING, CENTITVC CENTRE FOR NANOTECHNOLOGY & SMART MAT, EPFL - ECOLE POLYTECHNIQUE FEDERALE DE LAUSANNE, TWI

Abstract

A wire shaped coaxial photovoltaic solar cell comprising: a conductive core wire shaped support (401), a nanostructured semiconductor scaffold layer (402), one or more successive perovskite layers (403), an optionally provided hole transporting material layer (404), an outer conductor layer (405), an outer protective layer (406), characterized in that said outer conductor layer (405) comprises dispersed nanoparticles and said perovskite layers (403) are composed identically or wherein two or more of said layers have a different molecular structure and/or composition. The invention also relates to methods and apparatus for the fabrication of said wire shaped coaxial photovoltaic solar cell.

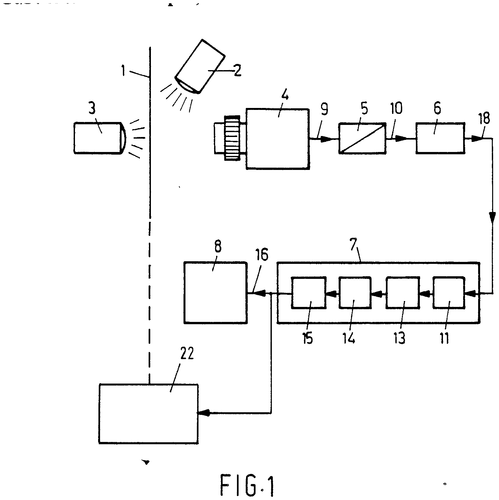

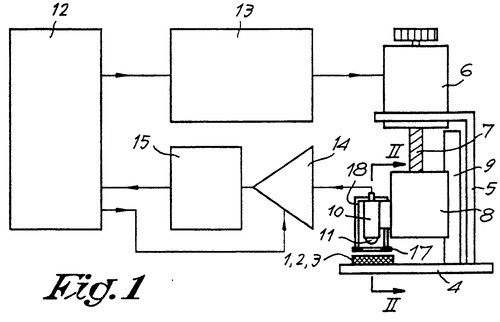

A method of measuring the yarn density of a woven fabric or the stitch density of a knit fabric for readjusting the production machine in question

Patent number: EP0277694

Date of publication: 1988-08-10

Applicant(s): CENTEXBEL, WETENSCHAPPELIJK EN TECHNISCH CENTRUM VAN DE BELGISCHE TEXTIELNIJVERHEID, WETENSCHAPPELIJK EN TECHNISCH CENTRUM VAN DE BELGISCHE TEXTIELNIJVERHEID AFGEKORT TOT CENTEXBEL

Inventors: BOSSUYT, FILIP OKTAAF PIETER

Abstract

A method of measuring the yarn density of a woven fabric or the stitch density of a knitted fabric by recording a video image of the woven or knitted fabric to be examined by means of a video camera, converting the video image by an analog-to-digital converter into digital video information, storing the digital video information in a digital image memory and converting said information by a central processing unit into the yarn density or stitch density. The digital video information is converted by a digital band filter (14) with central circle frequency (omega 0) into a yarn or stitch density, and that the digital band filter (14) is arranged in such a manner that it operates according to the formula: Yk= An.Xk-n+An-1.Xk-n+1.... + A0Xk-B1.Yk-1-B2Yk-2...-B.nYk wherein: Yk represents a series of points of the digital information characteristic at interspace T before the digital filtering; Yk represents the said series of points k of the filtered digital information characteristic via digital filtering at the same interspace T; the coefficients A and B are a function of the quality Q, the central circle frequency omega 0 and the interspace T.

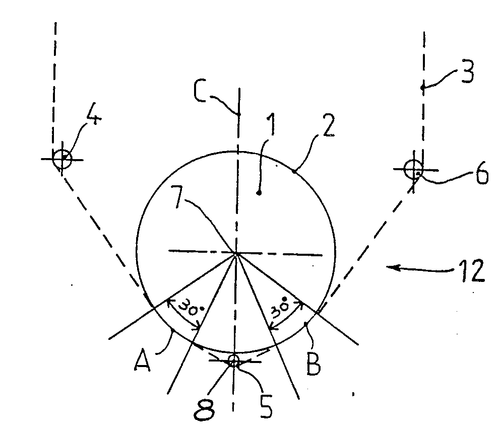

Device for measuring the yarn consumption of a textile machine

Patent number: EP0169766

Date of publication: 1985-12-27

Applicant(s): CENTEXBEL, FRANCE INSTITUTE TEXTILES, CENTRE TECHNIQUE INDUSTRIEL STYLED INSTITUT TEXTILE DE FRANCE, INSTITUT TEXTILE DE FRANCE, SANTEKUSUBERU

Abstract

his invention relates to an improved device for measuring the length of yarn absorbed by a textile machine, comprising in known manner a rotating member driven by the yarn during displacement thereof. It presents three fixed guides over which the yarn passes and which are positioned near the rotating member so that the yarn is in contact with the rotating member along two substantially equal arcs of low value, for example from 20 DEG to 50 DEG and advantageously 30 DEG . The device is more particularly applicable to measuring the length of yarn absorbed per stitch on flat knitting machines.

(From US4574598 A)

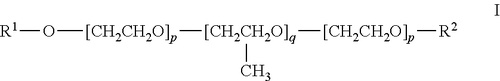

Methods and compositions for textile layers and coatings

Patent number: EP2567009

Date of publication: 2010-06-23

Applicant(s): UNIVERSITEIT GENT, WETENSCHAPPELIJK EN TECHNISCH CENTRUM VAN DE BELGISCHE TEXTIELNIJVERHEID

Inventor: HEBBRECHT GEERT, DUBRUEL PETER, VANNESTE MYRIAM, LAPERRE JAN, SCHACHT ETIENNE, SCHELFHOUT JORG

Abstract

A method for preparing a solid composite material comprising a structural polymer matrix and a thermo-responsive hydrogel involves: i) providing the structural polymer as monomer, oligomer or polymer particles, ii) providing a cross-linkable compound comprising reactive moieties which are mutually cross-linkable to form the thermo-responsive hydrogel, iii) forming a substantially homogeneous blend of the cross-linkable compound and the monomer, oligomer or polymer particles of structural polymer in a blended aqueous liquid, iv) inducing the cross-linkable compound to cross-link by a first induction means whereby the thermo-responsive hydrogel is formed, and v) forming the structural polymer matrix from the structural polymer by a second induction means. The resulting solid composite material provides a textile or membrane which presents a thermally insulating layer, through which air and/or liquid water cannot easily pass at low temperatures, but which also provides a more open structure at higher temperatures so that air and moisture vapour can pass through the textile or membrane allowing a wearer to be cooled by evaporation of sweat from the skin, to improve comfort. The membrane or textile permits water vapour to pass out through it even at low ambient temperatures, but water vapour permeability increases at higher temperatures, in order to prevent an active user from generating a layer of undesirable, un-evaporated sweat against the skin of the wearer.

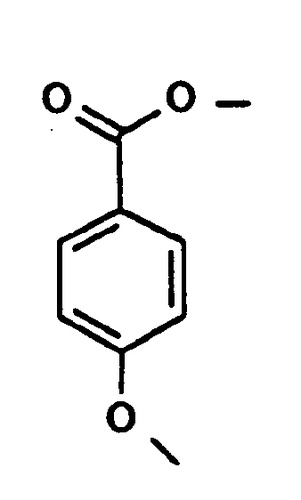

Dyeable and printable polypropylene composition and products manufactured thereof

Patent number: WO97/47684

Date of publication: 1997-12-18

Applicant: WETENSCHAPPELIJK EN TECHNISCH CENTRUM VAN DE BELGISCHE TEXTIELNIJVERHEID

Inventor: RUYS LUC, GODEFROIDT FRANK

Abstract

Polypropylene composition showing a good affinity for dispersion dyes and containing an isotactic polypropylene basic polymer and at least a copolyamide as dyeability additive, characterized in that it: a) comprises 80 to 99 % isotactic polypropylene basic polymer; b) comprises 1 to 10 % copolyamide component, consisting of the polycondensation products of at least two materials from the group, formed by: lactams, containing 6 to 12 carbon atoms, aminocarbonic acids, containing 6 to 12 carbon atoms, and equimolar quantities of a diamine, containing 4 to 12 carbon atoms, and a diprimary carbonic acid with 6 to 36 carbon atoms; and c) comprises 0 to 10 % ethylene/vinyl acetate (EVA) copolymer which contains 18-33 % (calculated on the basis of the EVA copolymer) vinyl acetate units, whereby all % are weight percentages.

Procedure for recognition of fibres in a group of chemically similar fibres and the determination of the quantity of such fibres in mixtures

Patent number: BE1004506

Date of publication: 1992-12-01

Applicant: WETENSCHAPPELIJK EN TECHNISCH CENTRUM VAN DE BELGISCHE TEXTIELNIJVERHEID

Abstract

Procedure for recognition of fibres in a group of chemically similar fibres and the determination of the quantity of such fibres in mixtures that contain such fibres. The procedure is characterized by the use of the analytical technique of near infrared spectrophotometry, in which light of various wavelengths is shone onto a sample of the fibres or mixture of fibres, the reflected light is captured, the captured light is quantified at these various wavelengths and used as the basis for recognizing the fibre or determining the quantity to be measured; this is done making allowance for the calibrations, which are measurements made on known fibres or mixtures of known composition.

Method and device for evaluating the quality of a layer of supple polymer foam.

Patent number: EP0457412

Date of publication: 1991-11-21

Applicant: WETENSCHAPPELIJK EN TECHNISCH CENTRUM VAN DE BELGISCHE TEXTIELNIJVERHEID

Inventor: BAETENS EDISTE,EDUARD JOSEPHIN

Abstract

Method for evaluating the quality of a layer of supple polymer foam (1), according to which method impression is made in the layer (1) with an impression body (11) and how the layer (1) reacts to this impression is verified, characterised in that with a pre-established constant in time impression in the layer (1) with the assistance of a dynamometer (10) the development of the force on the impression body (11) is registered in function of time and from this development in function of time a characteristic is calculated which depends upon the quality of the layer (1) and of which the relationship with the quality is already known via another method.