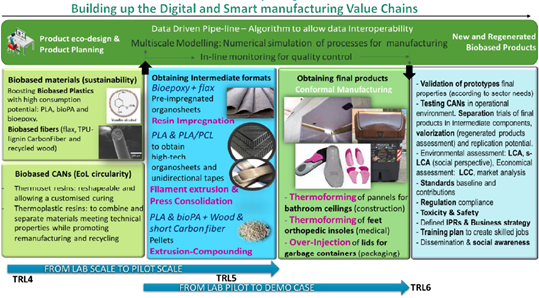

Bio-UPTAKE aims to promote a sustainable adoption (39% increase) of bioplastic composites in the European manufacturing industry through a combined green and digital transformation.

The project will therefore focus its scientific and technological efforts on creating flexible production methods for biobased products for construction, medical, and packaging, using a mixture of biopolymers reinforced with natural and/or biobased synthetic fibers that can be easily adapted to changing market demands.

Bio-Uptake's unique approach is based on modularity and prefabrication, which combines intermediate formats (organosheets, tapes, and pellets) into a final product, overcoming the current technical and environmental constraints to meet the demanding requirements of a specific sector/application where a single biobased material does not.

This synergistic approach to composite materials will encourage the integration and uptake of bio-based materials in mass custom manufacturing.

The project will develop three disruptive manufacturing processes, focused on the plastic manufacturing sector and demonstrated through three demo cases:

- Bathroom ceiling cabinet

- Feet orthosis

- Garbage container lid

Sustainability will be a top priority, with circularity by design being applied from the design phase, resulting in products with over 75% biobased content and a decrease in greenhouse gas emissions by 33%.

Centexbel is charged with

Multifilament extrusion of PLA and PCL

Monofilament extrusion of bicomponent filaments of PLA/PLA and PLA/PCL

Production of self-reinforced and microfibrillar reinforced composites

Consortium

The project is coordinated by

- Fundacion AITIIP – Spain

Project partners

- Centexbel – Belgium

- Fundacion Cidetec – Spain

- Specific Polymers – France

- Asociacion de Investigacion Metalurgica del Noroeste – Spain

- IRIS Technology Solutions – Spain

- SIMCON – France

- PODCOMP AB – Sweden

- COMFIL APS – Denmark

- Moses Productos SL – Spain

- University of Limerick – Ireland

- Polymeris – France

- Asociacion Espanola de Normalizacion - Spain

Acknowledgments

This project is Funded by the European Union under Grant agreement ID: 101057049