3D composite based on copper and graphene filaments with electroconductive properties for textile electrodes and flexible sensors

Patent number: RO135314

Publication date: 2021-11-29

Applicant(s): INSTITUTUL NATIONAL DE CERCETARE DEZVOLTARE PENTRU TEXTILE SI PIELARIE

Inventor: AILENI RALUCA MARIA, CHIRIAC LAURA, TOMA DOINA

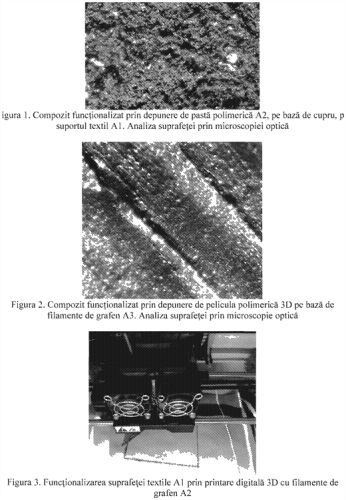

The invention relates to a 3D composite material with electroconductive properties which is meant for manufacturing electrodes for sensors, for technical applications in electronics and electrical engineering, in the medical field or for intelligent textiles. According to the invention, the material consists of three layers: a. the first layer (A1) is represented by a woven textile support of spun yarns of 100% cotton fibers, with a length density of 50 x 2 tex in warp, and of spun yarns of 100% cotton fibers with a length density of 50 x 3 tex in weft, the density ratio of the two yarn systems ranging between 3.22...3.85 and the mass per surface unit of the woven fabric ranging between 410...420 g/m2, b. the second layer (A2) is represented by a polymeric film made by mixing, with a mechanical stirrer, for 5...8 min, 15...20% Cu microparticles with 80...85% polyvinyl alcohol solution based on distilled water, of 99% concentration, magnetically stirred for 30...40 min at a temperature of 80...90°C, the percentage being expressed by mass, polymeric layer (A2) being deposited as a film by scraping or filming on the side 1 of the fabric of the layer (A1), followed by crosslinking at a temperature ranging between 150...170°C for 2...5 minutes, and c. the third layer (A3) is represented by a film deposited by 3D printing from graphene-based filament directly on the fabric of the first layer (A1) on which the polymeric film of the Cu-based layer (A2) was deposited.

Garment having knitted technical wire

Patent number: US20210360984

Publication date: 2021-11-25

Applicant(s): InDHouse Limited

Inventor: Tiffany Williams, Jackson Hoi Fung Chow, Vince Ho

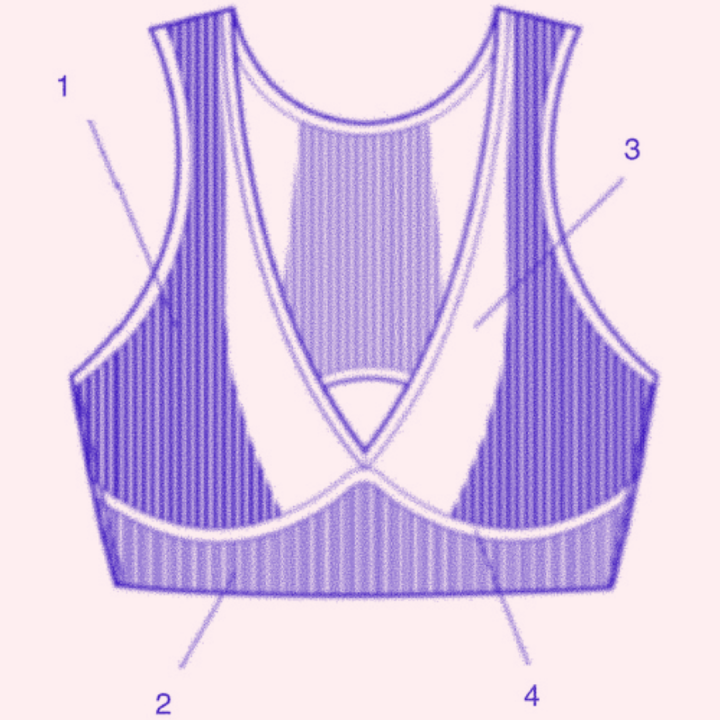

A knit garment having a knit technical wire is disclosed herein. The knit technical wire has two interwoven knit layers, such that they form an exterior or outward surface and an interior or body-facing surface. In between the exterior and interior surfaces and are at least one strand of yarn. The yarn may be a TPU yarn. The knit technical wire is used instead of a conventional underwire. The garment may be a woman's bra or dress that may conventionally be made with an underwire.

Personal protective riot equipment

Patent number: WO2022/032359

Publication date: 2022-02-17

Applicant(s): ALBERTO FERNANDES CARLOS

Inventor: ALBERTO FERNANDES CARLOS

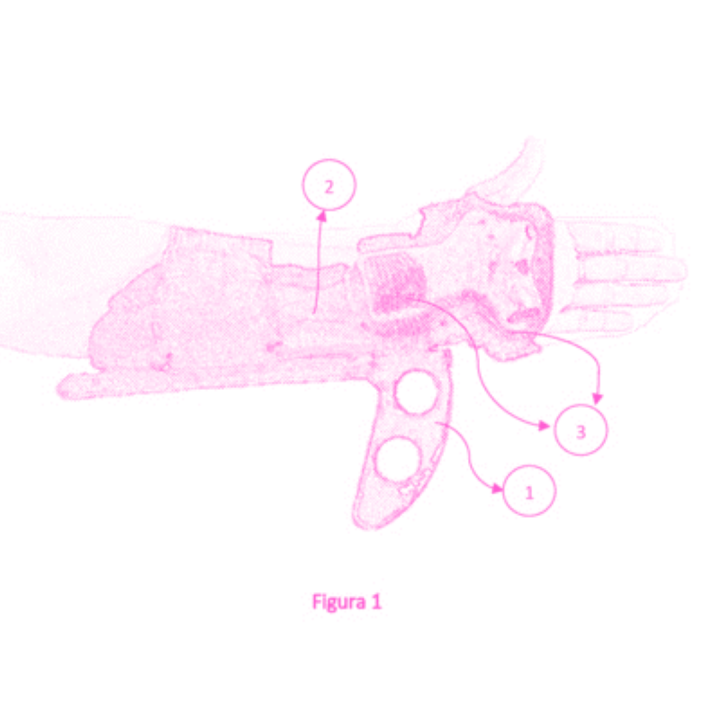

The present technology, which pertains to the technical field of urban personal defence equipment, is tactical personal protective riot equipment that has pressure claws (1) on the outside that are fastened to a fabric portion (2) attached to the forearm and hands of the wearer to block blows and objects during conflicts. Also known as a "stun block", the equipment was developed to help protect security agents in urban confrontations, especially in riots and protests where there are crowds of people, obviating the need to use batons, tonfas, bladed weapons or other items that could be lethal in combat.

Textile fabric, clothing, method for its manufacturing, functionalization of a textile fabric surface and use of a photosensitizer bonded to the surface of a textile fabric

Patent number: EP3933102

Publication date: 2022-01-05

Applicant(s): ORTNER CLEANROOM ENGINEERING

Inventor : RÖDER BEATE, ARMBRUSTER BIRGIT, KOFLER WOLFRAM

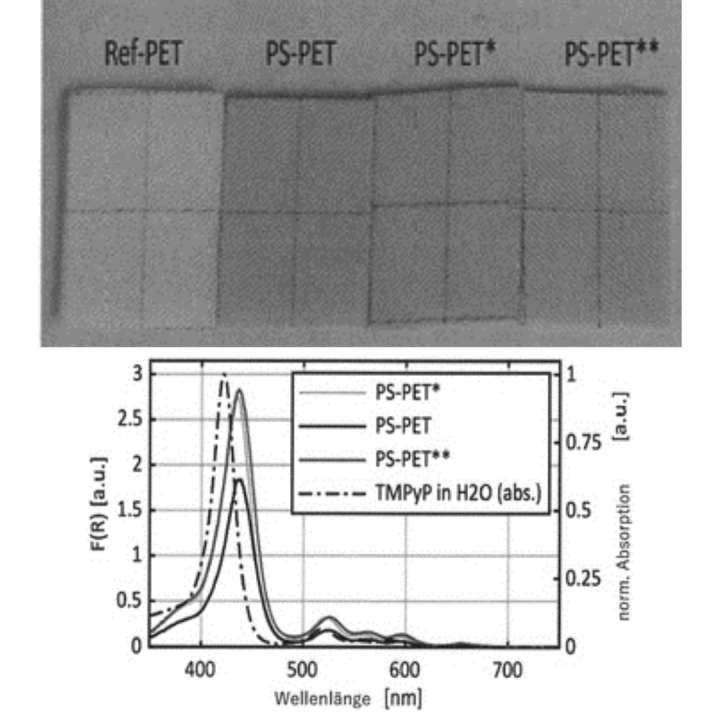

The present invention relates to a textile fabric which contains a woven fabric and/or a nonwoven, wherein the woven fabric and/or nonwoven contains fibres which optionally have at least in part a coating, wherein a dye, which has an antimicrobial effect when activated with electromagnetic radiation, is bonded to the fibres or to and/or in the coating. The present invention also relates to clothing made from the textile fabric, methods for producing and functionalising a textile fabric, and uses of a photosensitiser bonded to a textile fabric.

(From WO2022002489 A1)

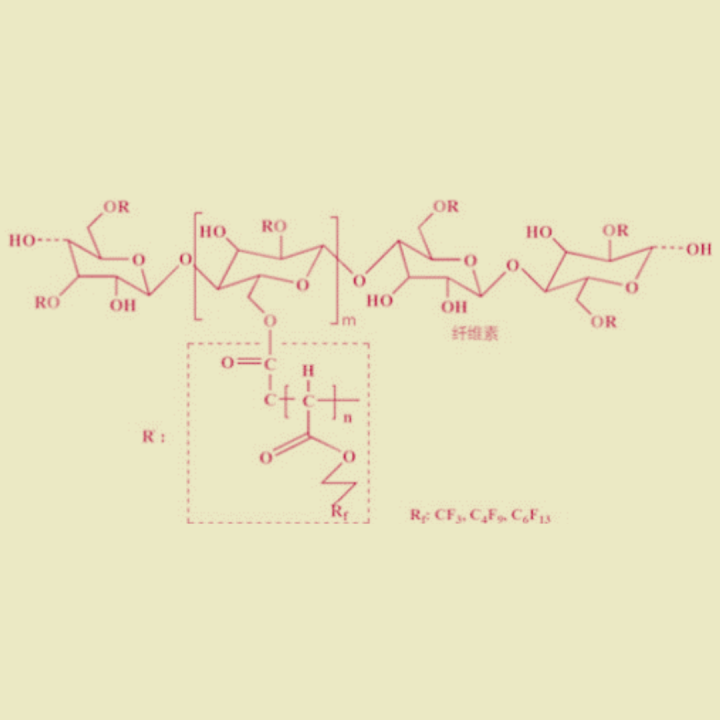

Water-repellent fabric and preparation method

Patent number: WO2022/018138

Publication date: 2022-03-17

Applicant(s): SOOCHOW UNIVERSITY

Inventor: ZONG YAKUN, LI ZHANXIONG, CHEN MINGQIANG, LI WULONG

Disclosed are a water-repellent fabric and a preparation method therefor. A short carbon chain fluoroalkyl alcohol with different fluorine atom numbers used as a starter is firstly treated with an acylation reagent to generate a short carbon chain fluoroalkyl bromoacetate, and is then synthesized with N,N'-bis(p-toluenesulfonyl)hydrazine to form a short carbon chain fluoroalkyl diazoacetate monomer; a fabric is respectively treated with an acylation reagent and N,N'-dimethylbenzenesulfonyl hydrazide in sequence to prepare a diazotized fabric having grafting sites on the surface thereof; and finally, a fluorine-containing polymer having a single carbon repeating unit is grafted to the surface of the fabric via a covalent bond by means of carbene polymerization, and thus a hydrophobic modified fabric is prepared. The entire reaction is carried out at a low temperature/room temperature, the operation is simple, and the process is environmentally friendly. Based on the single-carbon repetition and tridimensional regularity characteristics of a carbene polymer, under different conditions, fluorine-containing polymer roughening structures with different geometrical morphologies and sizes are constructed on the surface of the fabric in one step by self-assembly driven by carbene polymer crystallization induced on the surface of fibers, and uniform morphology and a controllable size are achieved to a certain degree.

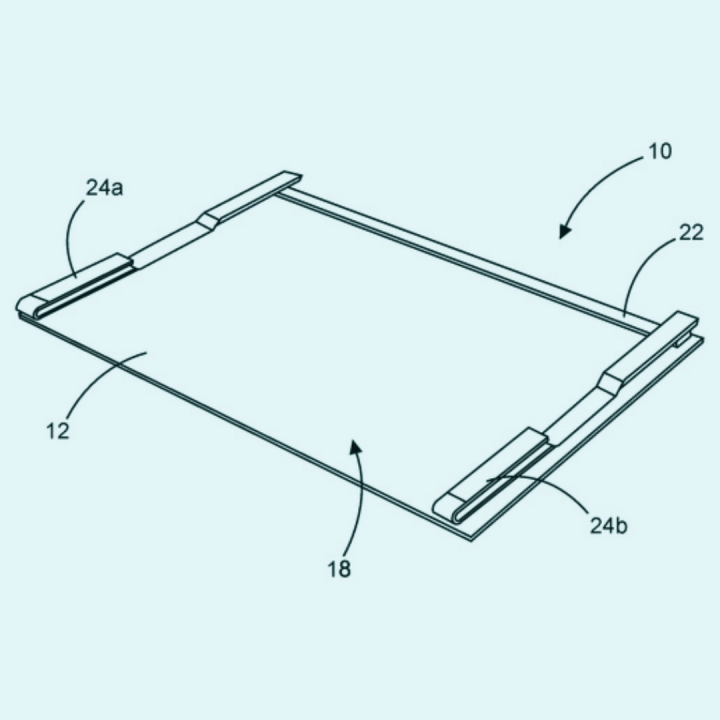

Fire protection packaging

Patent number: DE202021106124

Publication date : 2021-12-30

Applicant(s): KUETEMEIER

Fire protection packaging (10) for electronic devices (100), in particular electrical energy stores, having a foldable multilayer textile composite (12) comprising, arranged one above the other: - a first textile layer (14), wherein the first textile layer (14) comprises a first organic material and is at least partially configured, a second textile layer (16), wherein the second textile layer (16) comprises a second organic material, and - a third textile layer (18), wherein the third textile layer (18) comprises a third organic material, wherein a connecting element (22) is arranged on the side of the third textile layer (18) facing away from the second textile layer (16), which connecting element (22) is configured to function as a second part of a hook-and-loop connection, by folding the foldable multilayer textile composite (12) and connecting the connecting element (22) to the first textile layer (14), can be reversibly and non-destructively released and at least partially adapted in a form-fitting manner to the shape of electronic devices (100) of different dimensions in order to pack them at least partially.

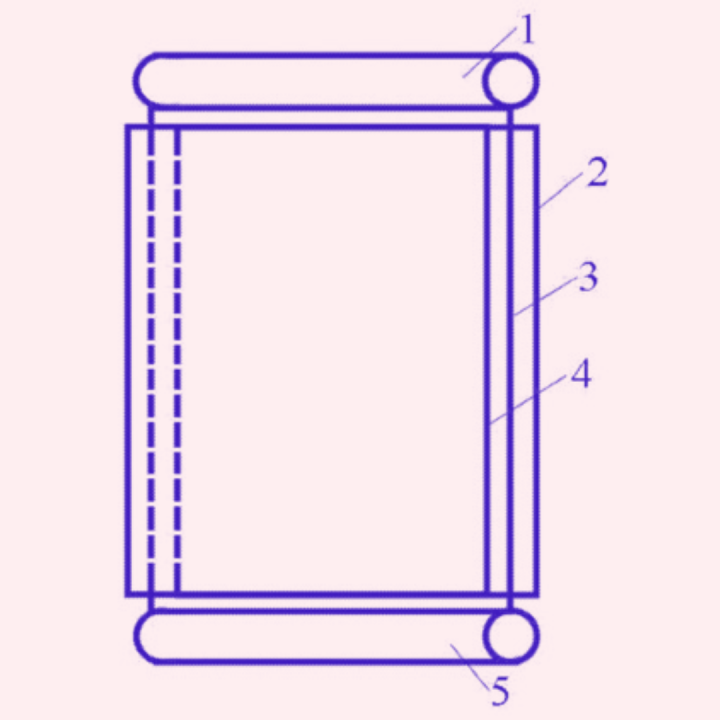

Bacterial cellulose-based air filter screen and use

Patent number: WO2021/237679

Publication date: 2021-12-02

Applicant(s): BAODING GUANGYU FRUIT PROC FOOD, HAINAN GUANGYU BIOTECHNOLOGY, HAINAN YEGUO FOODS

Inventor: ZHONG YUGUANG, ZHONG CHUNYAN

A bacterial cellulose-based air filter screen and a use. The bacterial cellulose-based air filter screen is of a three-layer structure, i.e., a layer of bacterial cellulose-based filter screen is sandwiched between two layers of polymer fiber filter screens; the polymer fiber filter screens are grid filter screens having a uniform size and formed by weaving polymer fibers by means of blended yarns; and the bacterial cellulose-based filter screen is formed by means of in situ synthesis of bacterial cellulose on a non-woven fabric by bacteria by means of fermentation. The bacterial cellulose-based air filter screen has a good particle filtering effect, large formaldehyde adsorption capacity, good antibacterial property, and a good static electricity bearing capability, can be used in manufacturing a window screen, an air conditioner filter screen, an air purification filter screen, and the like, and has a wide range of uses.

Removable self-adhesive fabric

Patent number: ES1286394

Publication date: 2022-02-10

Applicant(s): TORREGROSA PASCUAL VICENTE JAVIER

Inventor: TORREGROSA PASCUAL VICENTE JAVIER

Removable self-adhesive fabric characterized by it is obtained by: a) a first step (1) of choice of a cotton, polyester, acetate, rayon or material with equivalent characteristics, and/or its possible combinations; b) a second stage (2) of choice of decorative motif and subsequent computer treatment of adequacy of said image to large-scale or high definition format; c) a third stage (3) of large-format digital printing, with inks that use scattered dyes, pigments or reagents; d) a fourth step (4) of introduction of the product printed in an oven, at a temperature of the order between 15-200ºC for an estimated time between 1 and 3 minutes; e) a fifth stage (5) of washing the fabric eliminating excess ink, and subsequently, immersion in a fireproof product to prevent fire from falling, returning to be subsequently introduced into the oven, for drying; f) a sixth step (6) of support and body to the obtained fabric, through the work of an entertainment, where, by means of a "foulard", is submerged in removable adhesive and subsequently, it is squeezed to get the Excess adhesive, at the output of the "Foulard" the interlodel is already impregnated with adhesive by the two parts, and finally protecting itself by a protective role waxed by the two parts, thereby removing the list it ready to adhere to any surface or material; g) and finally, a seventh stage (7) where the fabric is placed a special laying table for this process, with built-in cutting blades, and where one of the protective papers of the interlining is removed, uniting the fabric on the part the reverse with the interlodel; and by a pressure roller, the two fabrics and the second protective paper are plated, leaving the coves joined perfectly in a uniform way; And where later, cuts are made, if necessary, between 70 and 80 centimeters for three meters.