A process for manufacturing waste textile fiber reinforced polymer composites and composites produced therewith

Patent number: WO2023/285891

Date of publication: 2023-01-19

Applicant(s): WIJESINGHE AROSH SANDEEPA

Inventor: WIJESINGHE AROSH SANDEEPA

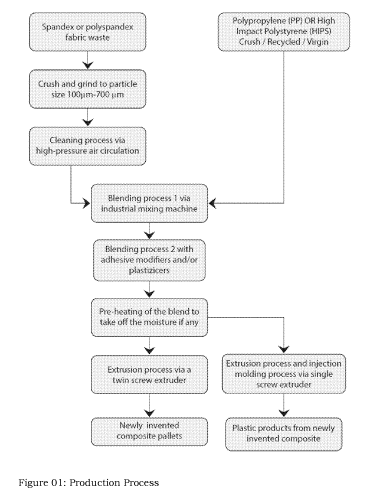

The invention discloses herein is a process for manufacturing waste textile fiber reinforced polymer composites, using spandex or polyspandex fabric waste blending with crushed and/or recycled and/or virgin polypropylene or high impact polystyrene. The fabric waste is crushed in to particles of size 100µm - 700µm and cleaned and blended with crushed and/or recycled and/or virgin polypropylene or high impact polystyrene and also with adhesive modifiers and/or plasticizers in accordance with predetermined ratios depending on the final product requirement. The mixture is pre-heated up to a temperature of 70°C - 90°C to take off the moisture therein and then subject to extrusion via a twin-screw extruder while controlling the barrel temperature between 160°C-220°C and the nozzle temperature increased to 2% to 10% of the moulding machine to achieve waste textile fiber reinforced polymer composite pallets.

Composite filtering material for making fabrics and its manufacturing process

Patent number: WO2022/229828

Date of publication: 2022-11-03

Applicant(s): LINARI MEDICAL

Inventor: LINARI STEFANO

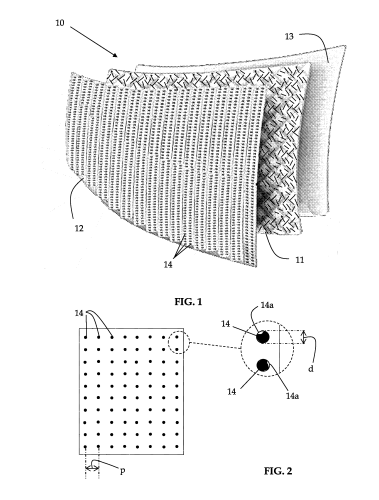

The present invention relates to a composite filtering material (10) comprising at least one intermediate layer made of nanomaterials (11) coupled with two layers of breathable material (12,13), and in interposition therebetween (12,13), the intermediate layer (11) and the layers of breathable material (12,13) being mutually constrained by a plurality of micrometric constraints made along an overlapping surface of the layers (11,12,13), wherein the micrometric constraints have dimensions measurable in terms of a diameter of a circumference inscribing each constraint, with the diameter (d) of such a circumference being less than or equal to 0.5 mm.

Composite sheet for absorbent articles, and composite sheet for waist parts of absorbent articles

Patent number: WO2022/209913

Date of publication: 2022-10-06

Applicant(s): UNICHARM

Inventor: MIYOSHI, Takayuki, MITSUNO, Satoshi, IKEUCHI, Norihito

The present invention provides a composite sheet for absorbent articles and a composite sheet for waist parts of absorbent articles, each of the composite sheets having excellent texture as a whole. A composite sheet 10A for waist parts of absorbent articles, the composite sheet having a first direction, a second direction and a thickness direction, which are perpendicular to each other. This composite sheet 10A for waist parts of absorbent articles sequentially comprises, in the thickness direction, a first nonwoven fabric, an elastic material that expands and contracts in the first direction, and a second nonwoven fabric, while being additionally provided with a plurality of point-like bonded parts where the first nonwoven fabric, the elastic material and the second nonwoven fabric are bonded with each other; and the bending stiffness of the composite sheet in the second direction as determined by a KES method is from 0.02 (N·m2/m × 10-4) to 0.65 (N·m2/m × 10-4).

Flat flexible composite material and method for the production thereof

Patent number: WO2023/011834 A1

Date of publication: 2023-02-09

Applicant(s): NUO

Inventor: ANTONELLI MARCELLO, ANTONELLI MARTA

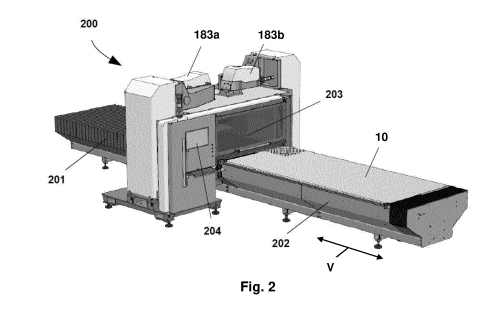

The invention relates to a method for producing a flat flexible composite material comprising a support layer made of a textile material and a cover layer made of wood veneer connected thereto. a groove structure is engraved into the wood veneer of the cover layer by means of laser engraving. In this case, the structure to be engraved is produced and read into a control device of a laser engraving apparatus, the composite material is placed on a work table and a laser head connected to the control device is activated in order to engrave the structure into the wood veneer of the covering layer. The invention provides that at least two laser heads of the laser engraving device connected to the control device are activated in order to simultaneously engrave the structure by means of the laser beam of a respective laser head into adjacent regions of the wood veneer of the cover layer of the composite material assigned to a respective laser head, wherein the laser heads are controlled in such a way that, in an overlap section of the adjacent regions of the composite material, the structure is engraved randomly by the laser beam of in each case one or the other laser head into the wood veneer of the covering layer.

Polylactic acid composite yarn, preparation method therefor and use thereof

Patent number: WO2022/242512

Date of publication: 2022-11-22

Applicant(s): HONG KONG RESEARCH INSTITUTE TEXTILES & APPAREL

Inventor: HUA TAO, HU HONG, YANG YADIE, JU ZIXIN

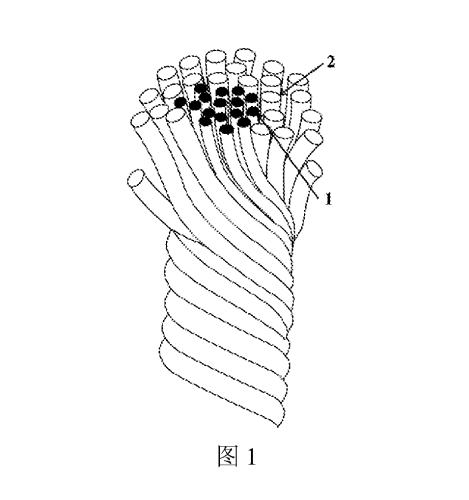

A polylactic acid composite yarn, a method for preparing the composite yarn and the use of the composite yarn. The polylactic acid composite yarn comprises two kinds of polylactic acid short fibers having different finenesses and/or lengths, such that on the one hand, the natural characteristics of biodegradability, renewability, skin-friendly and bacteriostatic properties and ecological and environmental protection properties of a polylactic acid are maintained, and on the other hand, the moisture absorption performance and quick-drying performance are improved. The method for preparing the composite yarn is simple and convenient to operate, easy to implement and suitable for large-scale industrial application.

Method and device for producing a textile fibre composite

Patent number: EP4067543

Date of publication: 2022-10-05

Applicant(s): MASCHINENFABRIK RIETER

Inventor: GRÜN THEO, BAUMANN MARKUS

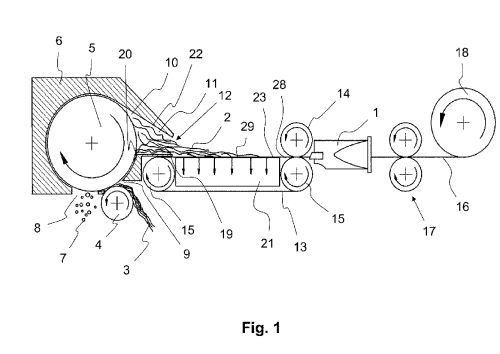

The invention relates to a method for producing a textile fibre composite. According to said method, a fibre mass (3) is separated into individual fibres (2) by means of an opening roller (5) integrated into a housing (6). The fibres leave the housing through a fibre outlet opening (10) by being detached from the opening roller at the latest at a knock-off edge (20) of the fibre outlet opening (10) and entering a fibre feed channel (11). The fibre feed channel is oriented towards a fibre collecting surface (23) and has a mouth (12). The fibres are then fed to the rotating, evacuated fibre-collecting surface (23) having a Perforation, deposited there, compacted and transported away. No negative pressure is applied to the mouth (12) of the fibre feed channel (11) and the fibres are thereby released from the opening roller without negative pressure and reach a fibre guide surface (19) of the fibre feed channel (11). In a corresponding device, the end of the cover surface (22) facing away from the opening roller (5) is at a distance (A) from the fibre collection surface (23), so that the opening (12) of the fibre feed channel (11) is free of negative pressure.

Method for automatically generating an artificial image of the reinforcement of a composite material

Patent number: FR3122273

Date of publication: 2022-10-28

Applicant(s): SAFRAN AIRCRAFT ENGINES

Inventor: SCHNEIDER JULIEN PAUL, FIXY TEDDY, WIELHORSKI YANNECK

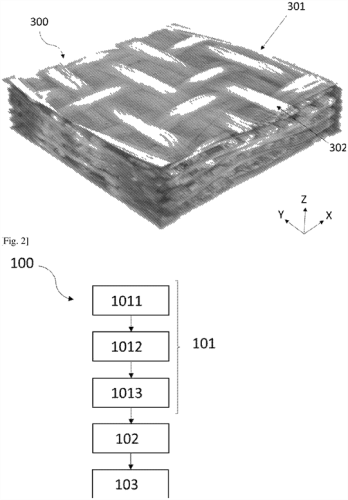

Method for automatically generating an artificial image of the reinforcement of a composite material One aspect of the invention relates to a method for automatically generating an image of the reinforcement of a composite material, comprising the following steps : Obtaining a set of data relating to the textile geometry of the reinforcement of the composite material, comprising for each reinforcement axis, a subset of data comprising for each section plane of a set of section planes perpendicular to the reinforcement axis, parallel and not coincident with each other, the barycenter and a set of points of the circumference of each section of reinforcing thread of the composite material included in the section plane, each barycenter and each point of the set of points of the circumference of a section of reinforcing thread corresponding to a reinforcing thread being assigned a label corresponding to the reinforcing thread, each section plane of the set of section planes being associated with a position on the reinforcement axis ; Generating an image of the reinforcement of the composite material from the set of data and the position on a reinforcement axis associated with each section plane of the set of section planes, and assigning each pixel of the image included in a reinforcing thread to the label associated with the reinforcing thread.

Formable and tear resistant polymeric composite

Patent number: WO2022/263585

Date of publication: 2022-12-22

Applicant(s): CANCO HUNGARY INVEST

Inventor: TEATHER ERIC, ELFERING BERND, HAUSMANN JOHANNES

A formable and tear resistant polymeric composite is both formable, such as through thermal forming, and tear resistant, wherein the composite has a high resistance to cut propagation. This combination of properties is achieved by combing an inner formable portion with a tear resistant outside portion and an inside portion, which may also be configured to be tear resistant. The inner formable portion includes a plurality of oriented polymer layers that are bound together by a lower melting temperature inner adhesive and enables thermal forming of the composite. The outside portion includes a woven fabric including polymeric strands, such as tapes, that are preferably oriented to increase strength and tear resistance. The separation of the woven fabric layers from the inner portion enables the composite to be formed into a shape, such as a shell for luggage, while having improved tear resistance.