1. What are the testing procedures and requirements for FFP respiratory masks?

In Europe, PPE products must comply with the Regulation (EU) 2016/425. Compliance with standard EN149 (Respiratory protective devices - Filtering half masks to protect against particles - Requirements, testing, marking) is the most common way to prove compliance with the Regulation. PPE masks shall have a CE-mark followed by the number of the notified body responsible for the production follow-up.

The Regulation (EU) 2016/425 requires manufacturers of PPE to comply with "essential health and safety requirements”. Within this regulatory framework, Article 3(1) PPE is primarily defined as: "Equipment designed and manufactured to be worn or held by a person for protection against one or more risks to that person's health or safety."

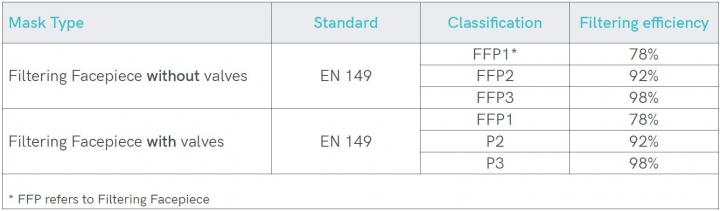

A subset of PPE, Respiratory Protective Devices (RPD) deals with products that provide breathing protection. To allow RPD products in the internal market and apply the CE mark, these products must be compliant with the requirements of the Regulation. European standards (EN) help manufacturers to comply with these requirements. Currently, there are around forty European standards, issued by CEN, and applied according to the type of the product. The table below provides a summary of standardized filter masks.

The European standard EN 149 specifies requirements for filtering half-masks to protect against particles. This standard is commonly used to assess the compliance with the requirements of the PPE Regulation before placing the masks in the European market.

The standard classifies masks according to their efficiency into three levels FFP1, FFP2, and FFP3. FFP3 have the highest filtering efficiency of 98% with 0.3 µm particles.

Only FFP3 and FFP2 are recommended for protection, while FFP1 masks are insufficient for the current situation around the Coronavirus (CoV-19).

Some masks are equipped with valves, while others are not. A valve is a device attached to the filter that allows more comfortable breathing and reduces heating of the filter element. The valve itself is not a filter and does not increase nor enhance protection in any way. Efficiency of the mask is still governed by its classification (FFP1, FFP2, or FFP3). Therefore, a mask with a valve should be certified via the EN 149 standard with a valid CE marking followed by the number of the Notified Body that authorizes its commercialization.

2. What is an FFP mask and what is it used for?

EN 149 describes it as "a particle filtering half mask covers the nose and mouth and the chin and may have inhalation and/or exhalation valve(s)."

The half mask consists entirely or substantially of filter material or comprises a facepiece in which the main filter(s) form an inseparable part of the device.

It is intended to provide adequate sealing on the face of the wearer against the ambient atmosphere, when the skin is dry or moist and when the head is moved.

Air enters the particle filtering half mask and passes directly to the nose and mouth area of the facepiece or, via an inhalation valve(s) if fitted. The exhaled air flows through the filter material and/or an exhalation valve (if fitted) directly to the ambient atmosphere.

These devices are designed to protect against both solid and liquid aerosols.

3. What is the difference between FFP1, FFP2 and FFP3?

Particle filtering half masks are classified according to their filtering efficiency and their maximum total inward leakage (more details in question 5). There are three classes of devices: FFP1, FFP2 and FFP3, the last one offering the highest level of protection.

The protection provided by an FFP2 or FFP3 device includes the protection provided by the device of a lower class or lower classes.

4. What must be tested: finished product or materials?

In the case of respiratory protective devices, standard EN149 imposes specific design requirements. In the process in view of certification, tests are done on the ready-to-use products. In the phase before certification (product development), companies should first evaluate the materials.

5. Which tests are FFP masks submitted to?

Total inward leakage

The laboratory tests shall indicate that the particle filtering half mask can be used by the wearer to protect with high probability against the potential hazard to be expected.

The total inward leakage consists of three components: face seal leakage, exhalation valve leakage (if exhalation valve fitted) and filter penetration.

For particle filtering half masks fitted in accordance with the manufacturer’s information, at least 46 out of the 50 individual exercise results (i.e. 10 subjects x 5 exercises) for total inward leakage shall be not greater than

- 25 % for FFP1

- 11 % for FFP2

- 5 % for FFP3

and, in addition, at least 8 out of the 10 individual wearer arithmetic means for the total inward leakage shall be not greater than

- 22 % for FFP1

- 8 % for FFP2

- 2 % for FFP3

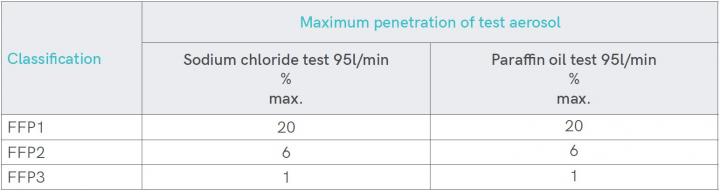

Penetration of filter material

The penetration of the filter of the particle filtering half mask shall meet the following requirements:

Compatibility with skin

Materials that may come into contact with the wearer’s skin shall not be known to be likely to cause irritation or any other adverse effect to health.

Flammability

The material used shall not present a danger for the wearer and shall not be of highly flammable nature. When tested, the particle filtering half mask shall not burn or not to continue to burn for more than 5 s after removal from the flame.

The particle filtering half mask does not have to be usable after the test.

Carbon dioxide content of the inhalation air

The carbon dioxide content of the inhalation air (dead space) shall not exceed an average of 1,0 % (by volume).

Head harness

The head harness shall be designed so that the particle filtering half mask can be donned and removed easily. The head harness shall be adjustable or self-adjusting and shall be sufficiently robust to hold the particle filtering half mask firmly in position and be capable of maintaining total inward leakage requirements for the device.

Field of vision

The field of vision is acceptable if determined so in practical performance tests.

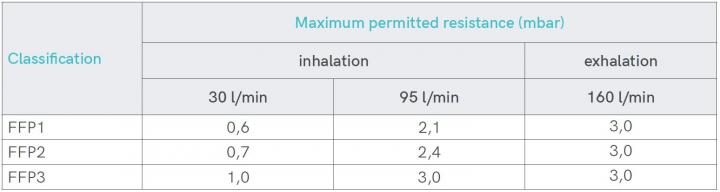

Breathing resistance

The breathing resistances apply to valved and valveless particle filtering half masks and shall meet the following requirements:

Clogging

For single shift use devices, the clogging test is optional. For re-usable devices the test is mandatory. Devices must be resistant to clogging (shown by a slow increase of breathing resistance when loaded with dust). The breathing resistances specified below shall not be exceeded before the required dust load of 833 mg-h/m3 is reached.

Valved particle filtering half masks

After clogging the inhalation resistances shall not exceed

- FFP1: 4 mbar

- FFP2: 5 mbar

- FFP3: 7 mbar

at 95 l/min continuous flow;

The exhalation resistance shall not exceed 3 mbar at 160 l/min continuous flow.

Valveless particle filtering half masks

After clogging the inhalation and exhalation resistances shall not exceed

- FFP1: 3 mbar

- FFP2: 4 mbar

- FFP3: 5 mbar

at 95 l/min continuous flow.

Penetration of filter material

All types (valved and valveless) of particle filtering half masks claimed to meet the clogging requirement shall also meet the requirements for the penetration test according to EN 13274-7, after the clogging treatment.

Demountable parts

All demountable parts (if fitted) shall be readily connected and secured, where possible by hand.

6. Does Centexbel perform tests according to EN 149?

Yes.

7. Does Centexbel issue the EU Type Examination Certificates?

Yes we do, we have recently been audited and accredited so that the certification scope of Centexbel (notified body 0493) is now extended to include respiratory protection. This means that we will be able to issue EU Type Examination Certificates according to EN 149.

Please note – only valid during the COVID-19 crisis:

For now, we only accept "certification applications" from customers who already dispose of all test results from an accredited lab. You must be able to prove this by sending the test scope of the lab under ISO 17025.

We are currently over-demanded, meaning that we do not have enough staff members to guide you through the necessary tests. This means that we can only respond to questions from customers who are already familiar with the standard.

To speed up the process, we are now working according to the 'COMMISSION RECOMMENDATION (EU) 2020/403' allowing us to use an Alternative Test Procedure. Certification during the corona health crisis will therefore take place on the basis of:

8. What information must be provided with and on the mask?

Marking on the packaging

The following information shall be clearly and durably marked on the smallest commercially available packaging or legible through it if the packaging is transparent.

- The name, trademark or other means of identification of the manufacturer or supplier.

- Type-identifying marking.

- Classification

- The appropriate class (FFP1, FFP2 or FFP3) followed by a single space and then:

- "NR" if the particle filtering half mask is limited to single shift use only. Example: FFP3 NR, or

- "R" if the particle filtering half mask is re-usable. Example: FFP2 R D."

- The appropriate class (FFP1, FFP2 or FFP3) followed by a single space and then:

- The number and year of publication of this European Standard.

- At least the year of end of shelf life.

- The sentence ‘see information supplied by the manufacturer’, at least in the official language(s) of the country of destination, or by using the appropriate pictogram as shown in the standard.

- The manufacturer’s recommended conditions of storage (at least the temperature and humidity) or equivalent pictogram, as shown in the standard.

- The packaging of those particle filtering half masks passing the dolomite clogging test shall be additionally marked with the letter "D". !

- This letter shall follow the classification marking preceded by a single space.

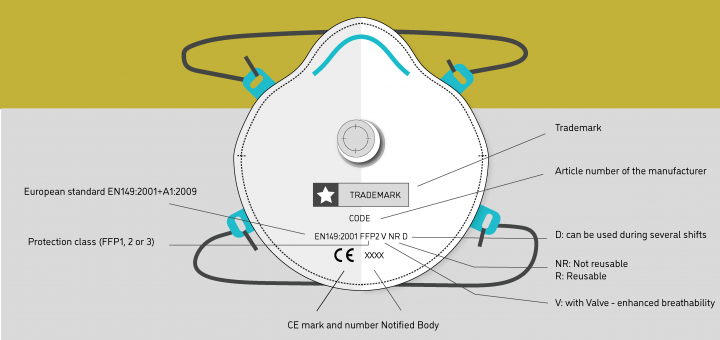

Marking on the Particle filtering half mask

Particle filtering half masks complying with this European Standard shall be clearly and durably marked with the following:

- The name, trademark or other means of identification of the manufacturer or supplier.

- Type-identifying marking.

- The number and year of publication of this European Standard.

- Classification

- The appropriate class (FFP1, FFP2 or FFP3) followed by a single space and then:

- "NR" if the particle filtering half mask is limited to single shift use only. Example: FFP3 NR

- or "R" if the particle filtering half mask is re-usable. Example: FFP2 R D.

- The appropriate class (FFP1, FFP2 or FFP3) followed by a single space and then:

- If appropriate the letter D (dolomite) in accordance with clogging performance. This letter shall follow the classification marking preceded by a single space. Examples FFP3 NR D, FFP2 R D

- Sub-assemblies and components with considerable bearing on safety shall be marked so that they can be identified.

Information to be supplied by the manufacturer:

- Information supplied by the manufacturer shall accompany every smallest commercial available package.

- Information supplied by the manufacturer shall be at least in the official language(s) of the country of destination.

- The information supplied by the manufacturer shall contain all information necessary for trained and qualified persons on

- application/limitations;

- the meaning of any colour coding;

- checks prior to use;

- donning, fitting;

- use;

- maintenance (e.g. cleaning, disinfecting), if applicable;

- storage;

- the meaning of any symbols/pictograms used of the equipment.

- The information shall be clear and comprehensible. If helpful, illustrations, part numbers, marking shall be added.

- Warning shall be given against problems likely to be encountered, for example:

- fit of particle filtering half mask (check prior to use);

- it is unlikely that the requirements for leakage will be achieved if facial hair passes under the face seal;

- air quality (contaminants, oxygen deficiency);

- use of equipment in explosive atmosphere.

- The information shall provide recommendations as to when the particle filtering half mask shall be discarded.

- For devices marked "NR", a warning shall be given that the particle filtering half mask shall not be used for more than one shift."