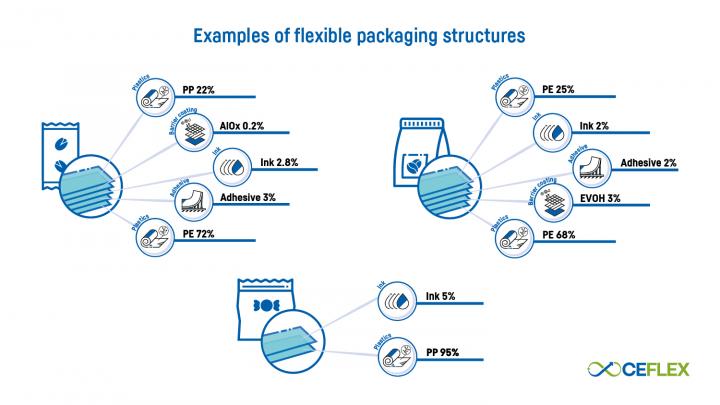

Thanks to the combination of ultra-thin packaging layers and high barrier properties, multilayer packaging are cost-effective solutions to extend food shelf life and to reduce waste. However, these multilayer packages are hard to sort and recycle, so many of them are simply downcycled (into products of lesser value) or incinerated with energy recovery.

Discarded plastic packaging still ends up massively in the environment as litter and are polluting oceans in the form of plastic soup and microplastics.

This led to a growing focus on circular packaging and ambitious targets such as the European 'Plastics Strategy' which states that 55% of all plastic packaging should be recycled by 2030. Fevia, the federation of the Belgian food industry, states that all food packaging should be reusable, recyclable or compostable by 2025. The roadmap "Food packaging of the future" mentions design for recycling as one of the important pillars to realize the transition to circular packaging.

Research shows that while it is possible to simplify packaging materials for some food products, other products still require more complex multilayer packaging to ensure the desired shelf life.

It is therefore very important to develop multilayer packaging that can be fully recycled.

Design to Recycle

Designing packaging to provide the required functionalities with a minimum use of resources, thereby minimizing product and packaging waste, remains key in a circular economy. It is however also important to design packaging that can be correctly disposed of, collected and efficiently sorted into suitable material fractions for recycling.

These sorted material fractions must be recyclable in order to replace virgin material.

Sorting plastic packaging

Near-infrared detection is the most widely used technique to sort waste streams. The disadvantage is that this technique is only able to analyze the outer layer of materials, up to a depth of 10 µm. The degree to which multilayer plastic packaging can be sorted thus depends on the composition of the packaging (i.e. thickness and position of the different material layers). In order to sort plastic waste into more single material flows and less mixed waste streams, it is important to develop packaging that is both suitable for recycling (Design for recycling) and easy to sort (Design for sorting).

Although it is technically possible to sort certain plastic packaging, the waste streams are often too small to make their further processing economically viable. For recycling companies, waste streams are only interesting from 250 ton/year onwards.

Mechanical Recycling

During mechanical recycling, plastic waste is processed into secondary raw materials or products, where the chemical compounds of the plastics are not broken down. The waste is (often first washed and then) mechanically ground and melted by an extruder and converted into granules.

Mechanical recycling is particularly suitable for waste streams consisting of a single type of (non-contaminated) plastic.

In principle, all thermoplastics can be mechanically recycled with little or no loss of quality. However, plastic waste is often a contaminated mix of materials. Because the recycled plastic may contain contaminants, the quality of the end product ultimately decreases. For this reason, strict regulations also apply to the application of granulate in food packaging, for example.

Although mechanical recycling is the most widely used recycling technique, it leads to degradation of the plastic material (e.g. drop in tensile strength), which reduces quality and value. Therefore, mechanical recycling cannot be applied indefinitely.

Chemical Reclycling

When plastics cannot be mechanically recycled according to the required standards from an economic and (environmental) technical point of view (e.g. multilayer structures of polymers with differing melting points), then chemical recycling can offer solutions.

During chemical recycling, the chemical structure of plastic waste is changed and broken down to the original building blocks (polymers, monomers or atoms) which can be used to make products such as chemicals or fuels in addition to new plastics. There are 4 different techniques for chemically recycling plastics:

- Solvolysis (dissolution)

- Depolymerization

- Pyrolysis (cracking)

- Gasification

These processes break down the plastic waste to produce synthesis gas (syngas) and liquid and semi-liquid products. Through new depolymerization processes, some types of plastics can be converted to monomers, for the production of new plastics.