Centexbel-VKC offers a plastic processing platform focused on material compounding, processing and on surface modification.

Compounding

Compounding consists of preparing plastic formulations by mixing and/or blending polymers and additives in a molten state, these blends are automatically dosed with fixed setpoints usually through feeders/hoppers.

The ThermoFisher™ HAAKE™ miniCTW (or mini-compounder) is very appropriate to compound and extrude small quantities. This conical double-screw compounder enables us to test a large spectrum of different materials and to screen a large number of processing conditions or product combinations in an affordable and quick manner. Ideal for tests with nanomaterials or engineered biopolymers.

The optional Force Feeder system enables a continuous material throughput. This screw-feeder is air-cooled to prevent clogging.

In addition to a continuous extrusion mode, the minicompounder allows a backflow mode through a recycle configuration, resulting in a optimised blend. The use of pellets involves that the material dosing is approached from a statistic distribution. However, this is solved by using powders or by partly mixing the blends beforehand.

The co-rotating and counter-rotating configurations guarantee an optimised blending. The heat regulation is limited to one single temperature for the entire barrel and cannot be divided into different zones.

The mini-compounder is computer assisted enabling the online follow-up and graphic display (in function of time) of temperature, screw speed and couple. It is also possible to add an event at a certain point of time.

Temperature can be set between ambient temperature and 300°C, with a heat output of 800W. The screw speed can be set between 10 to 360 rpm - max. couple of 5Nm.

Although it is possible to preset many parameters (temperature, screw speed and couple) it is not straightforward to upscale the process. However, by applying optimised process parameters, it is possible to produce blends with an extremely fine dispersion.

Underwater pelletizer

LPU™ Laboratory Pelletizing System connected to the Leistritz Masterbatch compounder

Underwater pelletizing for thermoplastic compounds

Compared to the “dry-cut pelletizing” systems the underwater pelletizer is less subject to wear and offers more flexibility during the production of thermoplastic compounds. The granules are perfectly spherical and there is no dust emission during the cutting process.

The pelletizing system interfaces with the twin screw compounder. The process is performed in a closed loop system. The pelletized product is conveyed by the process water from the cutting chamber into the centrifugal dryer. During the process, the pelletized product has no contact with the ambient air and there is no risk of gas, dust emission or contamination of the product.

The process water remains in the closed loop tempered water system, another advantage which contributes to the environment.

The Gala’s LPU™ Laboratory Pelletizing System is a small lab pelletizing system, designed for pellet rates up to 15 kg/h. The LPU™ Laboratory Pelletizing System includes an underwater pelletizer, a tempered water system, and a new and simple pellet dryer — all mounted on a single chassis with swivel casters.

Benefits

- Easy cleaning

- Simple & easy operation

- Lightweight, portable

- No movement of pellets against the dryer components

- Long life span of all parts coming into contact with the pellets

- Extremely gentle pellet-handling ensuring high product quality and minimale dust levels

- Reduced energy consumption: no additional heating required

- Wide variety of polymers: including high additive content, high viscosity to very low viscosity materials

This investment was made in the framework of the programme "Circularity in & with New Materials" aiming at optimizing the use of recyclates to promote the circular economy.

Flat Die Pelleting Press - Compactor

Since it is difficult to manipulate and convey low bulk density materials (e.g. fibres), their processing/recycling will often set a challenge. However, these processes can benefit greatly from transforming the material into dense pellets.

The compactor facilitates the production of these pellets by pushing low bulk density material through a die at high pressures. The resulting heat and shear cause the agglomeration of the material, leading to a more processable material.

Functioning

The Kahl 33-390 compactor is fed at the top with low bulk density material.

This material is then compressed by the rollers. When a sufficient amount of material has been collected, the pressure build-up will cause the material to be pushed through the die.

The compactor is equipped with 2 dies with different length/diameter ratios. This ratio has a major influence on the processing pressure and temperature of the material.

A cutter, underneath the die, cuts the compressed strands, and pushes them out.

Depending on the material, the rolls can exert more or less pressure, in order to better control the process.

The main parameters that control the process are the L/D of the die, the feed rate and the set pressure.

Injection moulding

The hydraulic injection moulding machine is available to analyse raw materials, to produce small test run series and to test new moulds.

- Possibility to fit Axxicon mold for the injection moulding of ISO test samples

- Possibility to apply personal inserts

Technical specifications of the Arburg Allrounder 320 S 500 - 150

- Max. clamping force: 500 kN

- Max. open (at min. installation height): 350 mm

- Min. installation height: 225 mm

- Dimensions clamping platen: 498 x 498 mm

- Bar spacing: 320 x 320 mm

- Flange diameter: 125 mm

- Max. ejector force: 30 kN

- Max. ejection stroke: 125 mm

- Srew diameter: 30 mm

- L/D ratio: 20/1

- Max. shot volume: 78 ccm

- Max. Couple on screw: 360 Nm

- Max. injection speed: 112 ccm/sec

- Max. dosing speed: 65 m/min

- Max. nozzle pressure: 50kN

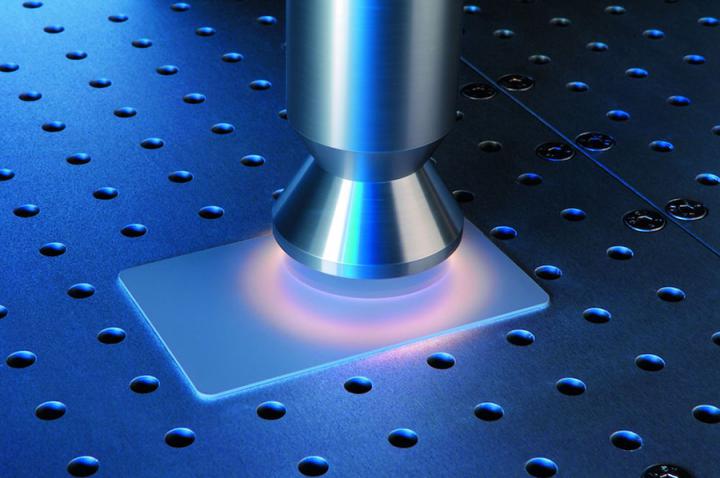

Surface modification

Some polymers contain apolar groups. Their surface is therefore low on energy and not easy to bond or wet. This results in poor adhesions of coating layers. To ensure proper bonding or coating a surface modification is necessary. This is done by oxidising the top layer and so introducing polar groups.

Atmospheric plasma

Plasma is a gas in which the gas molecules disintegrate into individual atoms, free radicals, electrons and photons. They bombard the plastic’s surface and lead to polar groups. In the case of atmospheric plasma, air is used instead of an inert gas.

Plasma technology is based on a simple physical principle. Matter changes its state when energy is supplied to it: solids becomes liquid, and liquids becomes gaseous. If even more energy is supplied to a gas, it is ionized and goes into the energy-rich plasma state, the fourth state of matter.

Method

A process gas such as air, nitrogen or mixed gases is guided through a jet in which a high voltage discharge turns it into Plasma.

This highly reactive plasma is electrical potential fire and will clean, activate or coat surfaces in order to create perfect adhesion or add functionalities (such as hydrophylic, Hydrophobic, anti corossion, ...)

Applications:

- surface cleaning

- plastic surface activation prior to bonding, printing, coating

- plasma coating