Context

Resistance to penetration and permeation are two variables related to the barrier properties of materials.

When determining the penetration resistance, the material is exposed on one side to the test liquid. In general, the test liquid is put under pressure and one visually observes whether the liquid penetrates through the material. Exactly this visual detection is the weakness of this test. The test result is a pass/fail.

A more complex test method is used to determine the permeation resistance.

Whereas in the case of a penetration test, the bulk liquid is forced through the barrier, the permeation test is based on a molecular diffusion of chemicals through the barrier. The sample is exposed to the test liquid on one side. By means of an instrumental method it is then determined when the test liquid breaks through the material on the other side. In such a test one determines the breakthrough time and sometimes also the permeation speed.

Method

The test assesses the permeability of protective clothing and gloves to chemical and biological liquids.

The applied standard is EN 374-3: 2015 – Protective gloves against chemicals and micro-organisms - Part 3: Determination of the permeation resistance to chemicals.

This European Standard specifies the determination of the resistance of protective glove materials to permeation by potentially hazardous non-gaseous chemicals under the condition of continuous contact.

Please bear in mind that the test does not represent conditions likely to be found in service, and the use of test data should be restricted to comparing materials chiefly on a relative basis in broad categories of breakthrough times.

Principle

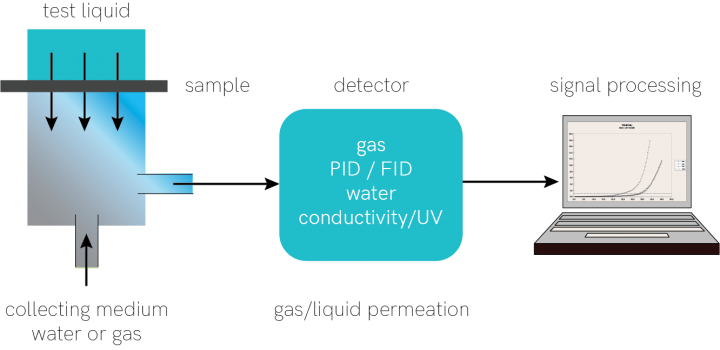

A test cell is composed of two compartments where the material is brought into contact with the test liquid.

The textile to be tested is placed in a test cell. One side of the textile is brought into contact with a test liquid. On the other side of the textile, the collection medium is located, that has to be screened continuously. The collection may be done either with gas (air) or liquid (water).

The detection in the case of gas permeation is performed by means of a PID. It is important that the test liquids are sufficiently volatile. The detection in the case of liquid permeation is performed by means of a conductometric detector. It is important that the test liquids are sufficiently water-soluble.

A test is typically performed during maximum eight hours, by which the performance level of the material is determined by the time a test liquid needs to break through. During this period the sample is continuously exposed to the test liquid.

Send your samples to

Centexbel - Chemical Lab

Technologiepark 70

9052 Gent-Zwijnaarde

Belgium

+32 9 220 41 51

gent@centexbel.be