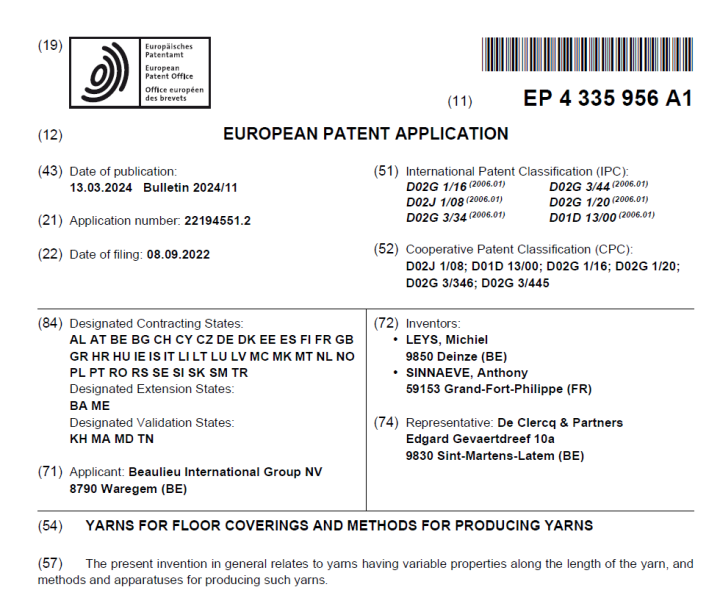

Title: YARNS FOR FLOOR COVERINGS AND METHODS FOR PRODUCING YARNS

Applicant: Beaulieu International Group NV

Inventors: Michiel LEYS; Anthony SINNAEVE

Patent number: EP4335956

Publication date: 2024-03-13

The current innovation pertains to floor covering yarns that display diverse characteristics along their entire length, as well as techniques and equipment for manufacturing such yarns.

The problem

Unlike weaving, tufting involves the implementation of a backing onto which the yarns are tufted. One of the main objectives of the carpet industry is to obtain carpets with a design defined by variations in colour and thickness, resulting in a more or less sophisticated design.

There are three main types of carpet finishes: (1) loop finishes, as they come out of the tufting process; (2) cut finishes, where the loops are cut to create a velvety appearance; and (3) cut loop finishes, where the top loops are cut to create the design. The carpet industry is increasingly divided into two segments: (1) high-volume products, which are structured according to a "volume-price" competitive strategy (e.g. the residential market); and (2) small and medium-volume products, which are customised to target specific markets (e.g. architects, small series for specific customers such as hotels and offices, also referred to as the "contract market").

Apart from the quality of the carpet, the main means of differentiation is the level of design. At this level, there are two main types of process:

- A process using raw white polyamide yarns printed after tufting can be carried out in two ways: a continuous process comparable to screen printing, or a process using digital printing. However, the quality of the final product remains limited: it is essentially a mass-produced product aimed at the low to medium "volume/price" segment, with limited reproducibility and, above all, poor wear resistance (problem of discolouration of the carpet after cleaning). These technologies are not suitable for small and medium quality series. A higher quality product can be obtained using digital printing, but this is very expensive. In addition, screen printing technology is very polluting (significant consumption of water, dyes, problems of waste water to be treated).

- A process using polyamide threads dyed in the mass, which can have a variable degree of deformation. In this case, the yarns can be shaped according to two main types of processes:

- twisting processes, where, for example, in the case of mechanically twisted yarns, the number of twists can vary from 30 to 300 turns per metre, which can include from 1 to 3 threads;

- entangling processes, where the threads are mixed, the mixture being fixed by knots created by punctual pressures of high pressure compressed air. These knots can have configurable frequencies, but with fixed sequences by introducing 1 to 6 yarns.

The design is typically created by varying the thickness, resulting in weaker areas that are more susceptible to wear for the same average thickness. The design can also be created with a level loop using a special tufting technology (also known as Colorpoint), which reduces the production speed by at least ¼. This also results in additional waste (10 to 15%) on the reverse side.

There are significant limitations to the ability to produce carpets with sophisticated designs and, in particular, it is virtually impossible to produce small and medium series of carpets with sophisticated designs under satisfactory industrial and economic conditions. Existing technologies are only suitable for mass production with a limited level of design quality (residential market), but are poorly suited to the contract market (e.g. public buildings, architectural projects, hotels), which consists of small and medium series with a specific level of design and high quality.

The solution

The innovation by Beaulieu International Group introduces a yarn that is now capable of being "programmed". By simply tufting the yarns, the carpet design can be automatically created. This means that the yarns are designed in a specific manner to produce the desired design as the tufting process advances. This advancement allows for complex carpet manufacturing processes to be conducted using basic and cost-effective tufting machines, eliminating the need for intricate designs made from multiple types of yarn spools.

As a result, a significant portion of the challenges faced in producing customized products in small to medium quantities with high design standards can be resolved.

The invention addresses this issue by adjusting the color contrast between 2 to 6 yarn ends, intertwining them in a random or predetermined sequence before undergoing the Air-Twisting process. The resulting yarn can then be utilized in a standard level loop-pile carpet. In certain scenarios, the yarn sections are crafted in a manner that enables a consistent yarn pattern variation to be replicated and tailored to complement a specific carpet design.

The invention describes:

- A device for entangling yarn to create a yarn that possesses varying characteristics throughout its length.

- A technique for manufacturing yarn that exhibits diverse properties along its entire length.

- A computer program or a storage medium containing instructions.

- Yarn with variable attributes throughout its length, which is produced using the aforementioned device and technique.

- A method for manufacturing floor coverings, including carpets, rugs, or artificial turf, with a diverse design on the surface.