Applicant: SPORTS AND LEISURE GROUP NV

Inventor(s): John PENNINCK

Patent number: EP4321685

Publication date: 2024-02-14

Field of invention

Artificial turf installations or synthetic turf mats are known as grass-like artificial surfaces made from synthetic materials such as polyethylene, polypropylene, polyamide, among others. Such artificial turf installations are generally used for sports that are originally or normally played on natural grass. An artificial turf installation is also used on lawns and in landscaping. The invention relates to an artificial turf mat and to a method of manufacturing an artificial turf mat.

The problem

The first artificial turf installations for sports were developed and installed in the early 1960s and had a much harder surface than natural grass. As a result, they caused more injuries when practicing sports. At the beginning of the 21st century, artificial turf installations with a sand and/or rubber infill were developed. Such artificial turf installations are often indistinguishable from natural grass from a distance and are generally regarded as much safer to play on than the first generation of artificial turf installations.

In general, an artificial turf installation consists of at least one type of artificial turf blades or tufts, a tuft cloth, a coating to keep the tufted artificial turf blades in place and, if applicable, an infill material and/or a shock-absorbing layer. The most common type of artificial turf installation uses synthetic grass blades, for example, of polyethylene, polypropylene or polyamide. These synthetic grass blades usually have a length between 10 and 65 mm and are tufted in a tuft cloth. The back of this tuft cloth is coated with a polyurethane or latex or polyolefin medium to fix the tufted synthetic grass blades in place.

The tufted artificial turf blades of the tufted and coated cloth are then filled with an infill material consisting of sand and/or performance infill granulate (e.g., rubber, cork, etc.). This keeps the artificial turf blades upright and improves the shock absorption and deformability of the artificial turf installation. The infill material usually forms a layer with a thickness of approximately 15 to 30 mm. The majority of manufacturers of FIFA-approved artificial turf installations use the technology described above. Known shock-absorbing layers have disadvantages due to a limited ability to drain liquids, such as water, from the artificial turf installation. Adding sand or other infill increases the risk of injuries.

There remains a need for a sports and recreational surface and subsurface that is stable, manages available moisture without degradation by water, is easy to drain, is easy and inexpensive to manufacture, and is hard enough to offer resistance, but is still resilient enough.

The solution

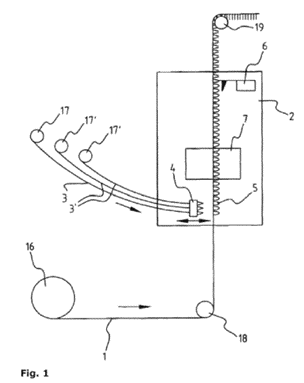

In a first aspect, the invention relates to an artificial turf mat comprising: a primary backing cloth (1), having a top surface and a bottom surface; a plurality of fibers (3, 3') extending above the top surface and that are tufted onto the primary backing cloth; and a primary coating on the bottom surface of the primary backing cloth, configured to fix the tufted fibers, wherein the plurality of fibers comprises a first type of fibers (3) and a second type of fibers (3'), wherein the first type are crimped fibers and the second type of fibers are substantially straight or spiral fibers and wherein at least half of the fibers of the second type extend above the fibers of the first type.

Because the artificial turf mat comprises a plurality of crimped fibers, these fibers act as a shock-absorbing/cushioning layer. These fibers allow water to flow through to the primary backing cloth when it rains. The artificial turf mat is able to drain excess water easily. The many crimped fibers ensure that the artificial turf mat is hard enough to provide resistance, but still resilient enough for an optimal playing experience. The artificial turf mat comprises a plurality of straight or spiral fibers that form a top layer. For example, the top layer ensures a good ball roll and a natural appearance. The artificial turf mat does not require infill to meet the requirements of EN 15330. This way there is no risk of microplastic infill spreading, there is less need for maintenance and there will be less wear on the fiber due to the absence of abrasive sand. Another advantage of the invention is that the shock-absorbing layer has improved shock absorption compared to existing artificial turf mats. In particular, the plurality of crimped fibers ensures a finally strong shock-absorbing layer that is also elastic.

In a second aspect, the present invention relates to a method an artificial turf mat comprising: tufting a plurality of fibers into a primary backing cloth having a top surface and a bottom surface; obtaining tufted fibers, which extend above the top surface and are attached to the primary backing cloth; applying a primary coating to the bottom surface of the primary backing cloth, suitable for fixing the tufted fibers; wherein the tufted fibers comprise a first type of fibers and a second type of fibers, the first type being crimped fibers and the second type of fibers being substantially straight or spiral fibers. This method has the advantage, inter alia, that it is easy to attach the two types of fibers homogeneously to the primary backing cloth. In addition, an optimal distribution and quantity of each type of fiber is achieved.

The higher fiber density also increases the resilience of the fibers, making them better able to recover their original upright position after loads, such as stepping on the mat. This ensures that the artificial turf looks fresh and cared for for a long time, even with intensive use. The combined properties of the bottom layer and the top fiber create an artificial turf mat with a good balance between stability, resilience and aesthetics. This makes the mat suitable for various applications, such as sports fields and playgrounds. The support of the bottom layer ensures that the artificial turf remains flat and stable, while the top fiber provides an attractive appearance and comfort for users. The right balance between the two types of fibers contributes to the overall performance and durability of the artificial turf, making it a suitable choice for a variety of environments and uses.

Advantages

Because the artificial turf mat comprises a plurality of crimped fibers, these fibers act as a shock-absorbing layer.

These fibers allow water to flow through to the primary backing cloth when it rains. The artificial turf mat is able to drain excess water easily.

The plurality of crimped fibers ensures that the artificial turf mat is hard enough to provide resistance, yet resilient enough for an optimal playing experience.

Because crimped fibers are used, a dense, shock-absorbing layer is created. This means that a filling with rubber or sand is not necessary. Sand also has an abrasive effect. The artificial turf field will therefore cause fewer wounds to the players.

Moreover, thanks to the use of crimped fibers, the artificial turf mat does not require infill to meet the requirements of EN 15330. This way there is no risk of microplastic infill spreading, there is less need for maintenance and there will be less wear and tear on the fiber due to the absence of abrasive sand.

Another advantage of the invention is that the shock-absorbing layer has improved shock absorption compared to existing artificial turf mats. In particular, the plurality of crimped fibers ensures a finally strong shock-absorbing layer that is also elastic.