Problem & needs

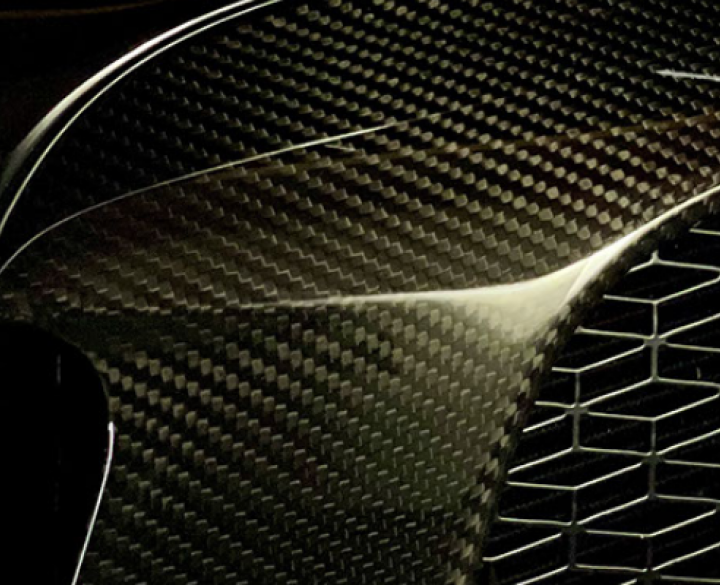

The increasing amount of carbon fibres (CF) that is used in the production of carbon fibre-reinforced plastics (CFRP) for applications in aerospace, transportation and automotive sectors, requires recycling strategies that allow a second life, and preferably a cascade usage of CF.

The market of recycled carbon fibres (rCF) is estimated to grow with 12.0 % until 2025 according to current studies, which indicates the urgent need of new strategies to develop process routes for rCF‐based composites.

Current recycling technologies for CFRP, e.g. pyrolysis or solvolysis, remove polymeric matrices and sizings from the CF. However, during these processes the CF filament surfaces are often damaged, limiting the reuse of rCF as reinforcing structures to increase the mechanical properties in composite materials.

Main objectives

The main objectives of ReCarboSize are the development of a concept for rCF sizing and the adaptation of the sizing itself for selected thermoset (epoxy (EP), polyurethane (PU)) and thermoplastic matrices (polyamide (PA6), polyphenylene sulfide (PPS)).

The rCF with chemically compatible and process adapted sizings are processed to nonwovens, which in combination with the matrices are used to produce lightweight components with improved mechanical properties compared to unsized rCF.

The project aims to achieve the following results:

- adapted sizings in combination with suitable matrix material for improved mechanical properties of rCF reinforced composites

- sizing adaptation for rCF on an industrial scale

- increasing the market acceptance of rCF among manufacturers of composite materials to expand the range of applications

- increasing the competitiveness of rCF compared to primary CF

- cost‐effective production of carbon fibre reinforced composites

- improved resource efficiency and sustainability

Partners

The project partners bring in the necessary, complementary competencies

- development of sizings for thermoplastic and thermoset matrices

- processing of rCF into nonwovens

- application of sizings on rCF and nonwovens

- composite processing and testing

Project financing

Cornet project with the financial support of the Walloon Region