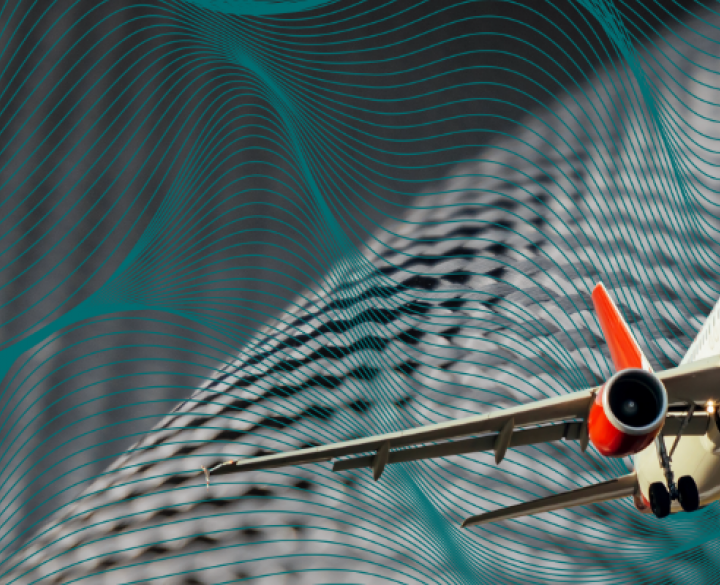

Currently, aeronautical composite material manufacturers produce 20 to 30% of waste after production. This waste consists of unimpregnated carbon fibres and carbon fibre prepreg that is pre-impregnated with polymer resin. In the Walloon region, this production waste, including fold scraps and expired rolls, is estimated to be 5t/year and could increase to over 35t/year by 2030-2040.

Unfortunately, most of this waste is currently either buried or incinerated because there are no technologies available to recover or utilize it. The focus has mainly been on recycling carbon fibres from polymerized waste generated during production or at the end of the product's life cycle. However, it is crucial to also consider recovering carbon fibres from the manufacturing stage, such as offcuts and expired rolls, as these materials still hold significant value.

In light of this, Centexbel, a specialist in fibrous materials, textile reinforcement, and composites, and UCLouvain, a specialist in resin behaviour studies, materials chemistry, and composites, are collaborating to develop environmentally friendly and cost-effective recycling methods for post-production scraps that are based on carbon reinforcement.

Aim and approach

The main goal of the REPREC project is to investigate and create recycling techniques that can effectively recover waste based on its specific characteristics. The project aims to design, develop, and evaluate a recycling method that utilizes the patchwork technique to reintegrate these scraps into industrial manufacturing processes. This method will be particularly suitable for applications that require high added value but have lower mechanical performance compared to aerospace applications.

In cases where the polymerized scraps cannot be reused in the patchwork structure, a chemical recycling method will be employed. Additionally, the project emphasizes waste collection, documentation, and raising awareness among producers regarding the new management approach.

The objectives of the project are

- To recycle high value post-production carbon fibre prepreg and dry carbon fabric waste from the aerospace industry.

- Ensure information management on the status of these wastes

- Raise awareness among the producers of this waste about the new management of these production scraps

- Adapt existing composite manufacturing techniques to these wastes with multiform geometries

- Environmental analysis of this recycling route and comparison with the current incineration process

- Design and testing of a demonstrator

The innovative aspects of the project are

- Recovery of post-production waste based on carbon fibres in the form of patchwork

- Development of new composite materials with a patchwork structure and controlled properties, using design software

- Reduction of environmental costs

- Chemical treatment of scraps that do not fit into the patchwork constitution

Consortium

Users Committee

Financing

This project is fully in line with the Strategic Innovation Areas favored by the Walloon Region which are DIS1 (Circular Materials-Recycling) and DIS3 (Agile and safe design and production modes).