More and more companies are implementing sustainability policies. One of the elements of this policy is to integrate recycled materials into new products. Not an easy task, because using recycled materials complicates the production process, so they do not offer a cheaper alternative to the original, virgin, materials.

In order to justify any additional price and at the same time demonstrate their sustainable approach and technical know-how, companies like to demonstrate to their customers/customers in black and white that their products contain (a certain amount of) recycled materials.

Unfortunately, it is extremely difficult to detect the presence of recyclate in a finished product. Yet we need a general and conclusive testing method to objectively refute any greenwashing and false claims.

In search of suitable tests

Currently, there is no general method by which we can demonstrate the presence of recycled material in all circumstances.

Although none of the existing test methods can give a definitive answer as to whether and how much recycled material is present in a finished product, some tests do prove their usefulness.

Below we discuss three different tests: one test to detect mechanically recycled cotton fibres and two tests to detect polyester recycled via melt extrusion.

1 - Cotton: microscopic method

Recycled cotton fibres usually come from clothing. They almost always include jeans (denim).

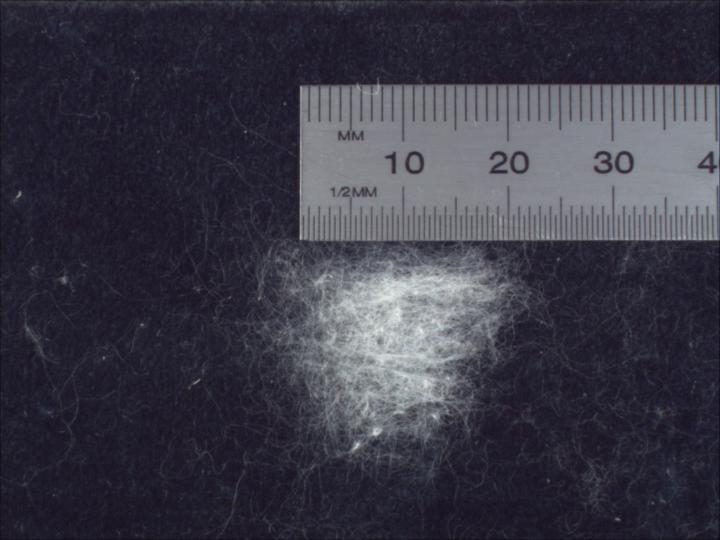

After the textile has been torn into small pieces, the fibres are "combed" out of the fabric and re-spun, either in combination with new fibres or not.

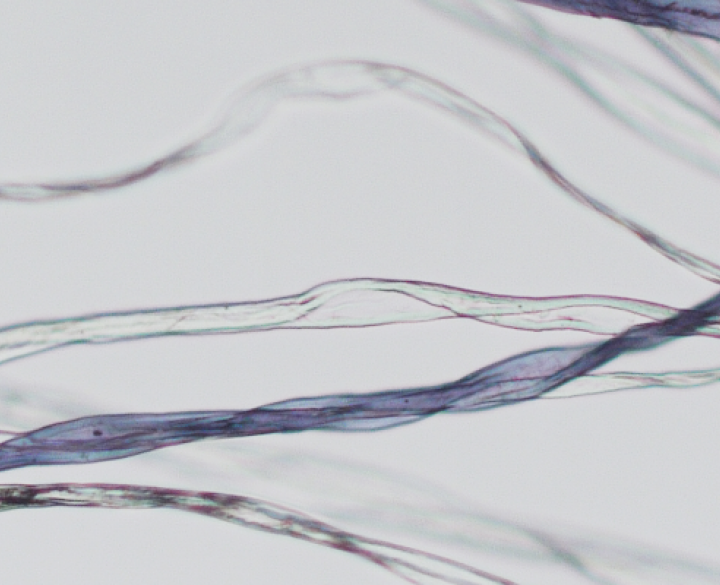

If we look at the newly composed yarn or fabric under the microscope, colour differences, fibre length as well as the frayed aspect of some fibres can give us an indication of the presence of recycled fibres.

(a) Colour differences: Under the microscope, we see blue cotton fibres among other fibres in an undyed or lightly dyed recycled fabric. Clear differences in the colour of fibres in a yarn of a uniformly dyed fabric indicate recycled material with a high degree of certainty.

A yarn contains fibres with different colours.

In the case of cotton, the entire yarn or fabric is dyed. So if we detect different colours (or ecru and colour) in one yarn, it means that the origin is different and at least the coloured fibres have been recycled from a yarn or fabric that was previously dyed.

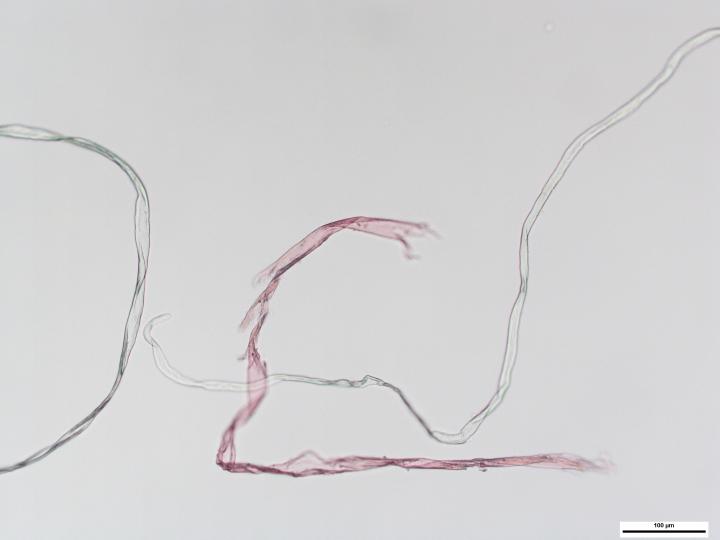

(b) Mechanical defects: The microscopic images show very clearly the effects of tearing or shredding. Torn fibres typically have frayed ends caused by this strong mechanical action.

The fibres have many mechanical defects, due to the fact that the fabric is first shredded (torn into pieces) to be recycled.

Nevertheless, we should be careful in our conclusions: it is not because we do not detect these typical characteristics of recycling that recycled material was not deployed. Several companies are trying to develop better and better processes, which no longer require mechanically destroying the fibres.

So: the better the quality of recycled fibres, the harder it becomes to recognise them.

(c) Fibre length: The length of the fibres present can also tell us something more: cotton fibres typically have a length of 2.5 to 4 cm. During recycling, fabrics are often cut into smaller pieces, which shortens the length of the fibres. A large amount of short fibres may therefore indicate recycled material.

Recycled polyester

2- Measuring via quality parameters

During thermal recycling (extrusion) of PET material into textile fibres, a quality loss always occurs, manifested for example by a reduction in intrinsic viscosity, a discolouration or change in crystallisation temperature.

These changes can be monitored in the form of quality control by comparing the raw material (collected polyester materials) and the final product during recycling.

However, these quality parameters are not suitable for determining the recycled content of a product present on the market, due to the fact that we do not know the starting material. That starting material may consist of fractions of different origins whose original quality we do not know.

With recycled material, we can therefore only measure the quality parameters at the end of the process. For example, a high viscosity may indicate a non-degraded product, but could equally mean that the virgin polymer had an even higher viscosity.

With recycled PET, as with cotton recycling, producers are increasingly in control of their production and quality losses are decreasing.

British Standard BSI Flex 6228: v2.0 - Plastic packaging. Assessment of recycled content within polyethylene terephthalate (PET) virgin material and recycle blended packaging materials produced from mechanical recycling methods. Specification and test methods - (published April 2022) is an example of a test method for determining recycled content in plastic packaging materials based on these quality parameters.

3 - Measuring by determining the IPA content

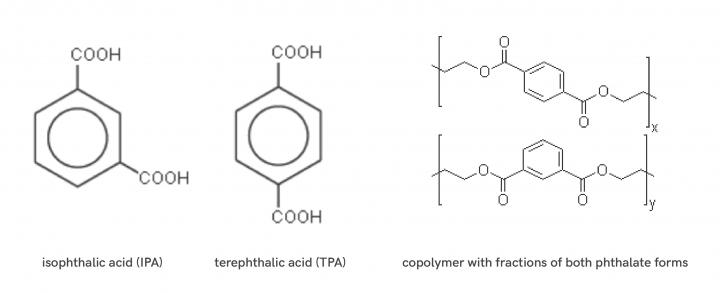

Polyester is the abbreviation for poly(ethylene terephthalate). In the production of PET, two monomers are condensed into a polymer: ethylene glycol and terephthalic acid. A copolymer is also usually used in the production of PET bottles. In that copolymer, a small fraction of the terephthalic acid is replaced by isophthalic acid (IPA). In textile materials, this copolymer is never used as a raw material for yarns.

PET bottles are the main source of post-consumer waste streams for recycling. Thus, many recycled polyester fibres contain components from PET bottles. As a result, unlike virgin fibres, these fibres will contain IPA.

The presence of IPA can be measured by various techniques (chromatography, NMR). Detection of IPA almost certainly indicates that material from PET bottles is present in the fibre.

Here, too, we have to be careful: the absence of IPA does not indicate that no recycled polyester is present. Indeed, other sources of waste streams may be used in which the copolymer is not present.

IPA is also used to calculate the percentage of recycled material. For this, it is assumed that PET bottles worldwide contain a constant content (± 2.3%) of IPA. So if we measure the ratio of IPA to normal terephthalic acid and arrive at a fraction of that 2.3%, we know the fraction of copolymer used in bottles. This assumes that this is also the fraction of recycled material.

However, we should point out that there are two preconditions that could lead to an incorrect conclusion: Not every PET bottle producer uses an IPA fraction of 2.3% and, in addition, there is the possibility that not the entire fraction of recycled polyester comes from PET bottles. Both these factors could lead to significant errors in the quantitative determination of rPET.

Currently, the IPA test is the only test on the market that offers a certain degree of reliability for the determination of recycled PET, although the results should always be interpreted with caution.

We continue to search for the ultimate test method

Centexbel is currently working on several research projects on recycled materials, including one project dedicated to the detection and evaluation of recycled materials with different techniques.

If you would like to have the recycled content of your materials determined, we are happy to refer you to the chemical or plastics lab.

You can also always contact your adviser with your questions.