This month, we present a selection of patents that solve current pressing challenges in the plastics and textiles sectors related to the circular economy from a material and process perspective.

Several patents focus on recycling methods that allow to preserve the properties of the source materials (textile fibres, high quality recyclates, selective dissolution) and target both single material (e.g. polyester or PET) and complex multi-layer or mixed post-industrial and post-consumer waste streams.

The present selection includes inventions covering steps from mixed waste sorting and pre-treatment such as deinking to selective recovery of valuable recyclates and reliable determination of the recycled content in materials produced using recycled fractions.

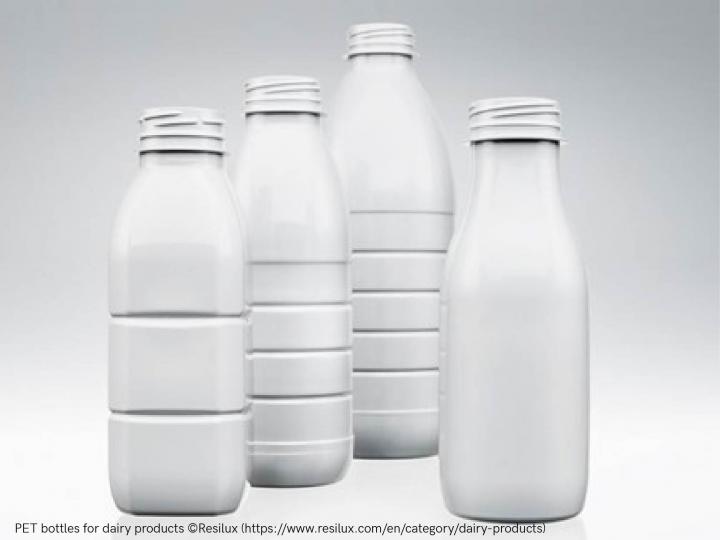

Method for processing dairy bottle recyclate in a new production of dairy bottles (closed-loop, bottle-to- bottle) and product obtained from it

Patent number: WO2023148678

Date of publication: 2023-08-10

Applicant(s): RESILUX NV

Inventor(s): LENAIN PIETERJAN, ANTHIERENS TOM, DE CUYPER DIRK

Motive for inventing

Beverage bottles for which no reuse is possible so far, are milk bottles. Polyolefin milk bottles coloured white are commonly known. PET-based, white-coloured milk bottles with a carbon black-based light barrier are becoming increasingly common. The processing of these milk bottles is problematic. When shredding the bottles, a stream of PET chips of grey colour is created. These is no sales market for this food-contact material. The material is considered waste and is incinerated.

Abstract

The present invention seeks to provide a solution for the sustainable use of polyester, preferably PET, in plastic packaging, in particular in beverage packaging and especially in milk bottles. The invention provides a method for processing dairy bottle recyclate in a new production of dairy bottles (closed-loop; bottle-to- bottle). The invention also provides a multilayer plastic bottle for containing and storing dairy products, obtainable by a method according to the invention

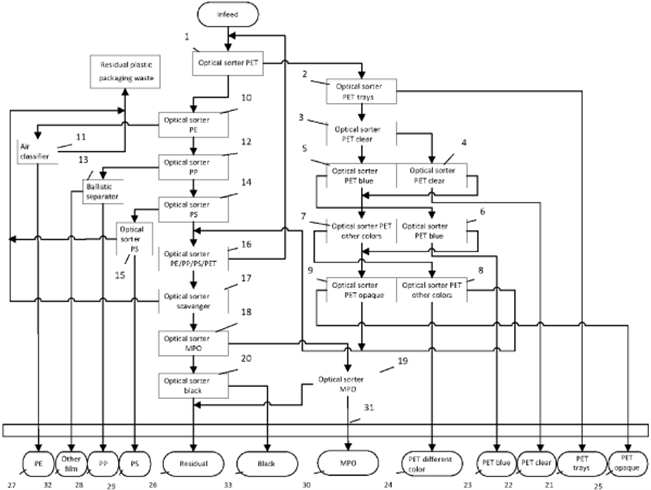

Method and device for sorting mixed plastic packaging waste comprising PE, PET, PP, PS, MPO, and films

Patent number: EP4177032

Date of publication: 2023-05-10

Applicant(s): INDAVER PLASTICS RECYCLING NV

Inventor(s): GODDAERT ERIC, MEYVIS ELINE

Motive for inventing

When recycling mixed plastic packaging waste, the challenge is to be able to distinguish the various types of plastic packaging waste (material) in a reliable and efficient manner.

Abstract

The present invention relates to a method for sorting mixed plastic packaging waste comprising PE, PET, PP, PS, MPO and films, wherein the mixed plastic packaging waste is first sorted by means of air classifiers, wherein the air classifiers sort the mixed plastic packaging waste into a lower-density fraction, comprising films, and a higher-density fraction, wherein the higher-density fraction is sorted on the basis of differences in reflection of electromagnetic radiation, resulting in a PE, PET, PP, PS and MPO fraction and residual mixed plastic packaging waste, wherein the PET fraction, comprising PET trays and colored PET, is sorted on PET trays by means of an optical sorter, wherein the PET fraction is then further sorted by color.

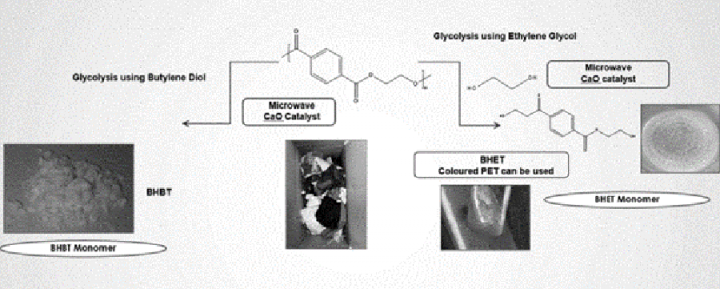

A method of recycling plastic waste

Patent number: EP4194490

Date of publication: 2023-06-14

Applicant(s): University College Cork-National University of Ireland Cork, Loughborough University

Inventor(s): ZANGANA KARZAN, FERNANDEZ-MATO ANTONIO, HOLMES JUSTIN

Motive for inventing

Chemical recycling has the potential to be able to recycle mixed plastic waste and more difficult to recycle packaging. Chemical recycling could solve the problem of downcycling by retaining the value of the monomers in plastics such as PET. However, current methods of chemical recycling, such as the widely studies glycolysis of PET, are often energy intensive and employ homogeneous catalysts that are difficult to recover and recycle, reducing chemical recycling as an economic and environmental viability process. Consequently, current chemically technologies for recycling PET cannot compete in price with virgin PET.

Abstract

The invention provides a method for recycling plastic products, such as low-value polyester and PET sources, e.g., mixed plastics, textiles, carpet fibres or similar, and the optional subsequent conversion of the chemical species formed during the recycling process into plastics of higher value (upcycling). The method involves depolymerising PET by microwave irradiation in presence of an heterogenous metal oxide catalyst and a solvent into its basic components (monomers) and optionally re-polymerising the components back into PET or into plastics of higher value. These higher value plastics may be polybutylene adipate terephthalate (PBAT) and polybutylene terephthalate (PBT).

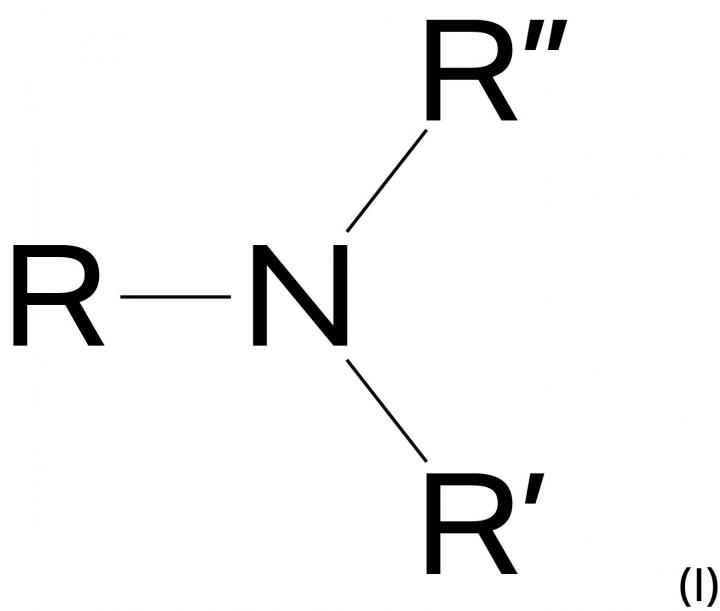

A method to deink and/or to delaminate plastic material using an amine

Patent number: WO2023111231

Date of publication: 2023-06-22

Applicant(s): UNIVERSITEIT GENT

Inventor(s): DE MEESTER STEVEN, ÜGDÜLER SIBEL, ROOSEN MARTIJN

Motive for inventing

Plastic packaging is typically heavily printed with inks, for example to provide information about the content and for marketing purposes to make them more appealing to consumers. Although inks are necessary components of plastic packaging, they are a significant source of contamination in plastic recycling. As all printed plastic films are generally collected and processed together, a low quality brownish, grayish, or black recyclate is obtained, making it only suitable for downcycled products. Thus, a need to deink packaging waste streams to enhance their application potential. Deinking of monolayer or multilayer plastic material, for example monolayer or multilayer plastic waste remains challenging and there is a need for improved methods to delaminate. Furthermore, there is a need to provide a method allowing to delaminate and deink in one step.

Abstract

The invention relates to a method to deink and/or to delaminate plastic material, preferably to a method to deink and delaminate plastic material in a single step. The method comprises the step of contacting the plastic material with an amine or a composition comprising said amine, wherein the amine comprises a nitrogen atom having at least one hydrocarbon substituent comprising an acyclic or cyclic alkyl group. The total number of carbon atoms of all hydrocarbon substituents of the nitrogen atom is at least five. The invention provides a method to deink and/or to delaminate and deink a wide variety of plastic material having different types of inks and/or including different types of multilayer plastic films, plastic material having ink on an outer surface as well as plastic material having ink covered by one or more layers, for example one or more polymer layer(s) in a single step without causing neither dissolution nor degradation of the main plastic components of the polymer material. The invention allows removing any type of inks from plastic material such as solvent-based inks, water-based inks and UV-based inks, either from monolayer or from multilayer plastic material, and is efficient in removing annoying odours. It is an object of the invention to provide an economic viable method to deink plastic material or to delaminate and deink plastic material, in particular plastic waste.

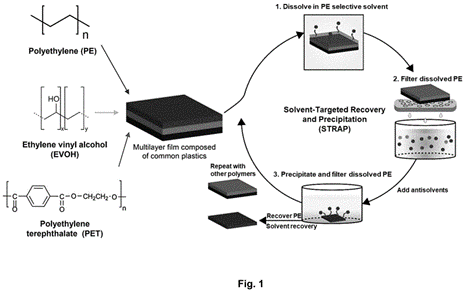

Recycling of plastics by solvent-targeted recovery and precipitation (strap)

Patent number: WO2023091639

Date of publication: 2023-05-25

Applicant(s): WISCONSIN ALUMNI RESEARCH FOUNDATION

Inventor(s): HUBER GEORGE, SÁNCHEZ-RIVERA KEVIN, VAN-LEHN REID, WALKER TED, ZHOU PANZHENG

Motive for inventing

Multilayer plastic films are ubiquitous in the flexible and rigid plastic packaging industry. These complex materials consist of distinct layers of heteropolymers such as polyolefins and polyesters, with each layer selected to contribute a corresponding property advantage to the bulk material, depending on the application. Technologies exist to recycle single-component plastics based on mechanical or chemically assisted methods, but no strategies exist to process multilayer films in closed-loop primary recycling schemes. Further technology development is needed for the more efficient collection, sorting, separation, and recycling of these multilayer packaging materials, as they represent an increasing amount of postindustrial and postconsumer waste.

Abstract

Disclosed herein is a method to recover constituent polymers in multilayer plastic films or mixed plastic wastes. The method comprises selectively dissolving a polymer in a solvent at a temperature, wherein the polymer is soluble, but other polymers in the multilayer plastic film or mixed plastic waste are not. The solubilized polymer is then separated from the multilayer plastic film or mixed plastic waste by mechanical filtration and precipitated by changing the temperature and/or adding a cosolvent. The process is repeated for each of the polymer component, resulting in a number of segregated streams that can then be recycled. The method further comprises (1) using computational tools including Hansen solubility parameters and molecular dynamics simulations to select the solvent and the temperature that selectively dissolves a polymer from among all of the components present in the multilayer plastic film or mixed plastic waste; (2) a deinking step to remove ink from the multilayer plastic film or mixed plastic waste before dissolving the polymer, and (3) cutting the multilayer plastic film or mixed plastic waste into stamps ≤1 cm2 or shredding the multilayer plastic film or mixed plastic waste before the polymer dissolution.

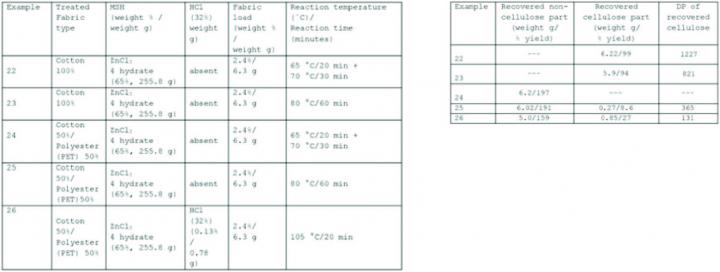

Method for reclaiming fibers from textiles waste

Patent number: WO2023194994

Date of publication: 2023-10-12

Applicant(s): BROMINE COMPOUNDS LTD

Inventor(s): RAPAPORT ELLA, BEN DAVID IRIS, BEN DANIEL REVITAL, MIASKOVSKI GERSHON, EDEN EYAL, HAKIMI ELAD, CHERNOMORDIK YURI, SHALEV ITZHAK, EPSHTEIN ASSOR YELENA, AMAR OREL, RACHMILEVITCH YAAKOV

Motive for inventing

There has been success on a smaller scale to effectively separate natural and synthetic blends, such as cotton/polyester blend, using chemical pathways. There are various enzymatic, solvent and hydrolytic methods to dissolve cellulose, polyester or both. However, scaling up these technologies to an industrial scale has proved to be technically and economically challenging. Moreover, none of these approaches leave both the cellulosic and the polyester components unaffected, nor do they provide any concepts for direct upcycling. Therefore, there exists a need for new recovery methods of blended waste textile products.

Abstract

A method for reclaiming fibers from a textile made of cellulose/ synthetic fiber blend, comprising adding the textile to a solution comprising molten salt hydrate (MSH) and an acid catalyst to form a reaction mixture in which cellulose fibers are fibrillated and depolymerized, terminating the reaction to obtain fibrillated and depolymerized cellulose, recovering the cellulose from the reaction mixture, and recovering the synthetic fiber.

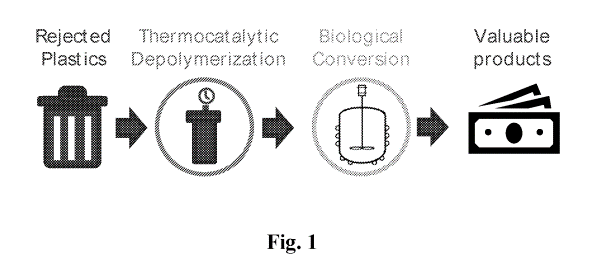

Upcycling mixed waste plastic through chemical depolymerization and biological funneling

Patent number: EP4263688

Date of publication: 2023-10-25

Applicant(s): ALLIANCE SUSTAINABLE ENERGY

Inventor(s): BECKHAM GREGG TYLER, ELLIS LUCAS DELANO, SULLIVAN KEVIN P, WERNER ALLISON JEAN ZIMONT

Motive for inventing

The provided methods and systems describe the breakdown of plastic materials into valuable products, thereby both eliminating waste and providing reusable materials.

Abstract

The described systems and methods utilize catalytic depolymerization and biological funneling via bacteria, which may reduce the costs of recycling plastics in terms of expensive catalysts, energy, and time. Advantageously, some embodiments may target mixed plastic streams, which due to having multiple chemical compositions, may not be easily recycled via conventional recycling techniques. Such mixed plastic streams are currently often discarded (e.g., landfilled) rather than recycled due to the cost and effort required for separating the various compositions present.

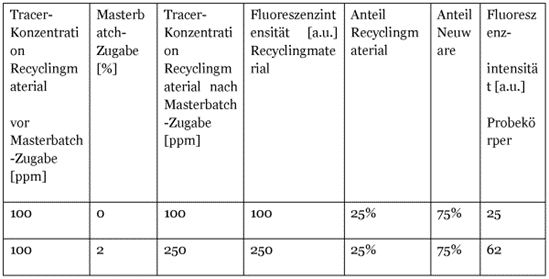

Method for producing a material with verifiable proportion of recycled material

Patent number: WO2023174487

Date of publication: 2023-09-21

Applicant(s): POLYSECURE GMBH

Inventor(s): KIRCHENBAUER DANIEL, MOESSLEIN JOCHEN

Motive for inventing

The recycling of recycled materials, i.e., of materials which originate from waste products, is essential to save raw material resources and to reduce production costs of new products. In the production of such products, it may be necessary to use a defined proportion of recycled material and be able to determine the fraction of recycled material in the new product.

Abstract

The method according to the invention serves to produce a material with a verifiable proportion of a recycling material. The material produced by means of the method thus comprises a proportion of recycling material and optionally a proportion of further material, for example a new material. The proportion of recycling material in the material produced can be checked to the effect that the proportion of recycling material can be reliably determined without knowledge about the parameters of the production process, in particular without knowledge about the amounts of recycling material and optional further material used in the production. The invention relates to a method for producing a material with a verifiable proportion of a recycled material. The method comprising the following steps: (1) providing a first material, the first material consisting of a recycled material and optionally a tracer; (2) identifying the tracer in the first material; (3) determining a signal intensity of the identified tracer in the first material; (4) setting a target signal intensity by (4.a) adding a further amount of the identified tracer to the first material depending on the determined signal intensity if the determined signal intensity is less than the target signal intensity, or (4.b) adding further recycled material or a mixture of further recycled material and tracer, the signal intensity of the mixture being lower than the target signal intensity if the determined signal intensity is greater than the target signal intensity, so as to obtain a second material which comprises the recycled material and the tracer and has the target signal intensity; and (5) optionally, combining the second material with a third material in a defined ratio, the third material being a material that does not contain the identified tracer, so as to obtain the material with verifiable proportion of recycled material.