The constantly growing global production of plastics has an enormous impact on the environment. More in particular, the pollution by micro and nanoplastics threatens wildlife and human health. This pollution is caused by the breaking down of plastic items that are discarded into nature into microscopically tiny particles, under the influence of wind, (sea)water, uv radiation and microbiological activity.

The analysis of complex samples (food samples or samples taken from nature) reveal that microplastics tend to be embedded in other materials, requiring time-consuming (bio) chemical purification and separation procedures. Moreover, the use of corrosive chemicals such as KOH, HNO3 or NaOH is dangerous and can lead to the degradation of microplastics.

To resolve this problem, the European Commission has filed a patent (under WO2020/157208) related to the invention of a two-step method to detect nano- or microplastic particles embedded in a heterogeneous matrix material:

- One part of the matrix material comprising nano- or microplastic particles is applied onto the surface of a conductive support to form a first layer (L1) with an average thickness of ≤ 10 pm.

- L1 is irradiated by an ion beam, forming as such an irradiated layer (L2).

- The nano- or microplastic particles are detected in L2 by either mass spectroscopy, Raman nanoscopic or infrared nanoscopic techniques or by a charge dependent detection method or a combination of these techniques.

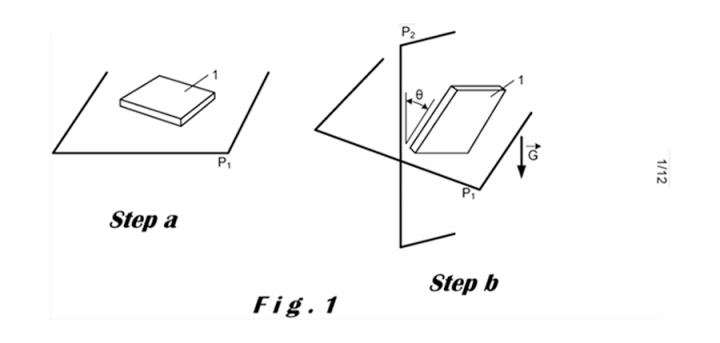

After formation of the first layer (L1), a drying step is preferably performed. During or prior to the drying step, the conductive support is substantially parallel to a first horizontal plane P1. Then, the conductive support is positioned so as to form an angle Q ranging from +60° to -60°, preferably ranging from +45° to - 45°, preferably ranging from +30° to -30°, more preferably ranging from +15° to -15° relative to a second vertical plane P2, even more preferably substantially parallel to the second vertical plane P2.

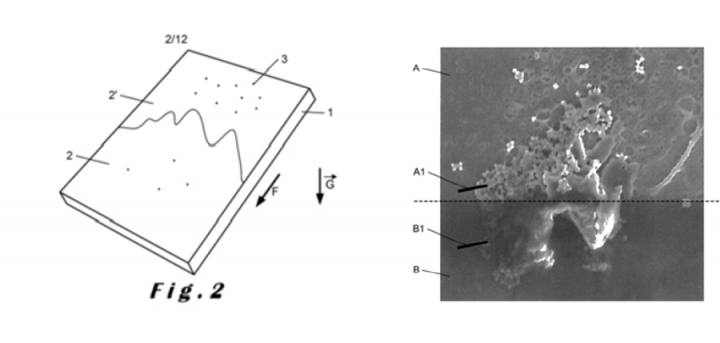

This figure shows the effect of the positioning step shown in Figure 1 on the first layer (L1). Due to the position of the conductive support 1 resulting from said positioning step shown in Figure 1, bottom part 2 of the support 1 is lower than the top part 2’ of the support 1. Consequently, in the layer (L1), gradients of matrix and nano and micro plastic particles 3 are created because of the combined actions of gravity and capillary forces. The concentration of nano and micro plastic particles relative to the total concentration of the heterogeneous matrix material becomes higher on the top part 2’ of the support than on the bottom part 2 of the support. As a result, the nano and micro plastic particles located on the top part 2’ of the support are more easily detected than the nano and micro plastic particles located on the bottom part 2 of the conductive support 1 during the detection step c) of the method according to the present invention.