Flame retardancy is a sought-after functionality for textiles and polymeric materials.

This month's patent alert highlights eight recently published patent applications that address or improve the burning behaviour of these materials.

Formulation and preparation of flame-retardant silicone polymer material

Patent number: AU2022235642

Publication date: 2024-04-11

Applicant(s): Tahiti

Inventor(s): Liu Guiyu

Summary

The present invention disclosed a formulation and technical process in artificial leather manufacturing to supply variety of industries. It specifically provides a flame-retardant silica gel leather preparation method thereof For years leather has been largely used in furniture, electronics, apparels and interior trim material in all automobiles, however the limitation and risks in safety, wear resistance, antistatic, waterproof; oil- proof; stain resistance, fire resistance and anti-fogging performance etc. have brought more and more attention to the inventor in related industries. In order to improve the safety performance of the automobile, the inner decorative blanket and the sun-shading curtain of the automobile are usually required; the seat fabric and the ceiling fabric have flame retardant performance; most of the flame retardant leather for automobile interior trim is sprayed with a layer of flame retardant on the surface of the leather; the flame retardant effect is limited; and the flame retardant effect is gradually reduced along with the use of the automobile interior trim leather; and the safety performance of the automobile is affected. In comparison with traditional textile base cloth and a finishing layer coated on the textile base cloth, wherein the finishing layer is made of silica gel material, and the silica gel material comprises the following parts by weight: Raw materials: 0-55 parts of vinyl MQ silicone resin, 0.1-0.5 parts of platinum complex catalyst, 1-8 parts of modified aluminum hydroxide, 0-5 parts of polymethyl silicate, 2 silylation reagents -6 parts, butyl titanate 0.2-0.6 parts, filler 8-16 parts, base rubber 100-130 parts, distilled water 1-3 parts, crosslinking agent 0-10 parts, stabilizer 0.1 0.5 parts and coupling agent 0.5-4.5 parts. The silicone leather of the present invention can make leather products have good flame-retardant performance and fire resistance performance, as well as good tear strength, tensile strength and elongation at break without using flame retardants. performance, can be large-scale industrial production.

Use of poly(dimethyl vinylphosphonic acid-vinyl imidazole) copolymer in the making of fire retardant materials

Patent number: WO2024005736

Publication date: 2024-01-04

Applicant(s): Bursa University

Inventor(s): Kara Ali

Summary

The invention relates to the use of poly(Dimethyl vinylphosphonic acid-vinyl imidazole) copolymers in the production of fire retardant materials in areas such as textile, building-construction, cable and wire production, electrical-electronic equipment, transportation and automotive.

Encapsulated flame-retardant compositions, methods of making them, and articles including them

Patent number: WO2024155755

Publication date: 2024-07-25

Applicant(s): Albemarle

Inventor(s): Daniel De Schijver

Summary

In one aspect, the disclosure relates to flame-retardant plastic compositions including a polymeric component and a brominated flame retardant (BrFR), wherein the BrFR includes one or more particles at least partially encapsulated by a thermoplastic toughener. In some aspects, encapsulation can take the form of a core-shell structure wherein the shell has an average thickness of about 5 nm to 10 μm. The thermoplastic toughener can be selected from a styrenic block copolymer, a thermoplastic polyurethane, a nitrile butadiene rubber, an acrylic elastomer, a copolyester elastomer, a thermoplastic polyether ester elastomer, a thermoplastic amide ether elastomer, a chlorinated rubber, an ionomer, a thermoplastic vulcanizate, and combinations thereof. The flame-retardant plastic compositions additionally include a filler and/or a compatibilizer. Also disclosed are methods for making the flame-retardant plastic compositions and articles made from the compositions.

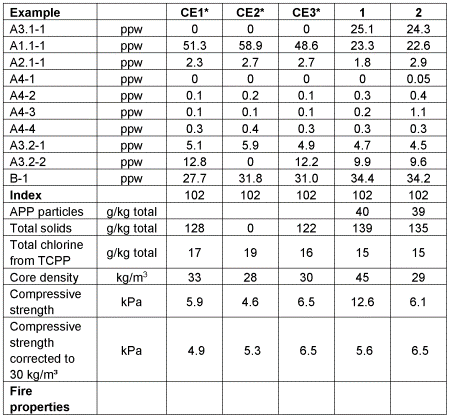

Ammonium polyphosphate particles as a flame retardant in polyurethane foams

Patent number: WO2024189143

Publication date: 2024-09-19

Applicant(s): Universiteit Twente

Inventor(s): Stefan Peil

Summary

The present invention relates to particles comprising a core comprising a water-soluble ammonium polyphosphate and a shell comprising polyphenols, and to the use of these particles as flame retardants, in particular in polyurethane foams.

A burning-resistant thermoplastic composition

Patent number: US20240352255

Publication date: 2024-10-24

Applicant(s): UPM Kymmene

Inventor(s): Barbara Gall

Summary

A burning-resistant thermoplastic composition comprising at least one polymer and a lignin-based filler is disclosed. Further, is disclosed the use of a lignin-based filler for producing a burning-resistant thermoplastic composition and a method for producing a burning-resistant thermoplastic composition. Further is disclosed an article and the use of the burning resistant thermoplastic composition.

Flame retardant textile product

Patent number: US20240318366

Publication date: 2024-09-26

Applicant(s): Perrone Leather

Inventor(s): Bartle Avery

Summary

An improved fire resistant textile product that includes a substrate base layer. The substrate base layer may comprise a needle punched, nonwoven substrate formed from a synthetic material such as a polyetherimide fiber. A first coating is applied to the substrate. The first coating may comprise a mixture including: about 1-65 wt. % aluminum trihydroxide; about 1-33 wt. % polyurethane polymer; and about 1-11 wt. % H2O. An effective amount of pigment may be added to the above composition to produce a desired color. The first coating may be applied in two steps with a first rolling application followed by a spraying application to provide a coated substrate. Finally, a clear top coat may be added to the coated substrate. The finished textile product may have a maximum acceptable two minutes total heat release (HR) of 65 KW min/m2 and a peak heat release of 65 KW/m2.

Fire-resistant compositions

Patent number: US20230374319

Publication date: 2023-11-23

Applicant(s): Hexion

Inventor(s): Daniel Pacheco

Summary

Embodiments of the present disclosure generally relate to fire-resistant compositions and to coated substrates and articles comprising such compositions. In an embodiment, a fire-resistant composition is provided. The fire-resistant composition includes particles having a core-shell structure. The fire-resistant composition further includes an intumescent, a blowing agent, a catalyst, and a binder. In another embodiment, a coated substrate is provided. The coated substrate includes a substrate having a fire-resistant composition disposed thereon. In another embodiment, a fire-resistant article is provided. The fire-resistant article includes a flexible substrate having a fire-resistant composition disposed thereon.

Lightweight fire-resistant plate-like composite material

Patent number: WO2024107053

Publication date: 2024-05-23

Applicant(s): Holland Composites

Inventor(s): Sven Janssen

Summary

The present invention relates to a lightweight composite material suitable for use in the manufacture of fire-resistant insulation panels, comprising a lightweight core layer sandwiched between two com- posite fibre-reinforced resin layers. In particular, but not exclusively, the present invention relates to a composite material suitable for use as architectural insulation panels comprising a first layer compris-5 ing polyfuranyl resin and glass fibres, a core layer comprising an insulation material, and a second layer com-prising a cured polyfuranyl resin and glass fibres. The composite material may comprise one or more additional outer coating and structural layers on one or both sides of the composite material.