Applicant: ONTEX

Inventors: Eva Staelens, Dries Cobbaert, Lieven Dhooge, Chaminda Koralalage, Roderick Davidson

Patent application number: EP4000570

Problem

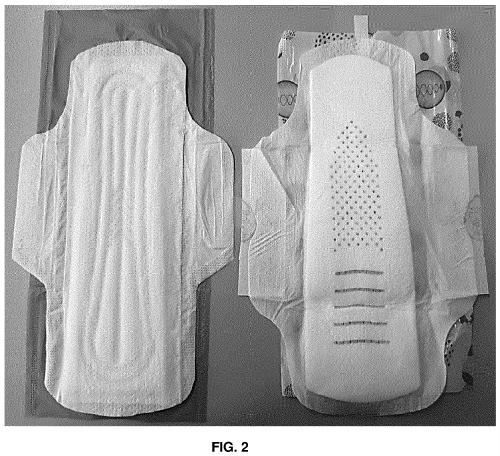

Absorbent articles for personal hygiene are disposable articles such as wound dressings, pads, lactation pads, heel pads, and maternity towels. Disposable personal hygiene absorbent articles typically include a liquid permeable top and an impermeable back sheet, with an absorbent core enclosed in-between both layers.

The present invention relates to these absorbent cores comprising foam material.

The ability of such products to acquire, distribute, and store bodily fluids (urine, sweat, feces, liquid stools, blood and menses) is obviously important to their function. Historically, this has been primarily achieved by using high lofty nonwovens and cellulosic fibers and/or superabsorbent particles. This approach has, however, encountered a number of difficulties in achieving efficient removal of fluid from the body of the wearer and storage away from the wearer, leading to visible stains on the body facing side of the articles, as well as in providing proper flexibility and comfort, i.e. by following the user's movements and the shape of the body when being worn.

In the past decade intensive research and development has been carried out in the development of foams designed for disposable personal hygiene products. However the speed at which the absorbent article absorbs liquid is low.

Therefore it is needed to further optimize the efficient fast absorption of body exudates (to help preventing leaks), and reduced rewet (which offers a drier feeling for the wearer), at a reduced cost.

Solution

The invention relates to an absorbent core for an absorbent article. The absorbent core comprises a foam layer incorporating a nonwoven fabric and a top and bottom surface. The top surface contains one or more indented compressed portions and one or more raised non-compressed portions. The absorbent core includes a nonwoven containing superabsorbent polymers.

A limited amount of superabsorbent polymers, e.g. fibers or particles, may be present in the part of the foam layer between the nonwoven fabric and the foam layer bottom surface. The quantity of superabsorbent polymers is preferably sufficiently low to avoid any curling of the absorbent article, for example less than 20 gsm. Advantageously the SAP included in the foam are selected to be permeable to prevent affecting the acquisition time of the absorbent article, and/or to have a low CRC to avoid a too strong swelling and to reduce the gel blocking effect. The SAP comprised in the nonwoven may on the other hand be selected to have a higher CRC. The SAP included in the foam may thus show a higher permeability and/or a lower CRC than the SAP comprised in the nonwoven.

The foam layer may have a maximum thickness of 5, 4, 3 or 2 mm or less. The thickness of the raised non-compressed portions is preferably between 2 and 3 mm, and the thickness of the indented compressed portions is preferably between 0.7 and 1.5 mm. The foam comprises an open cell polymer foam, more preferably foams selected from the group consisting of polyurethane (PU), poly vinyl alcohol (PVA), polyolefins such as low-density polyethylene (LDPE), ethylene-vinyl acetate (EVA), ethylene butyl acrylate (EBA), open cell silicone foams, natural and synthetic rubbers, and mixtures thereof, most preferred being aliphatic polyurethane foam. These may be either hydrophilic or hydrophobic, at various degrees of hydrophilicity.

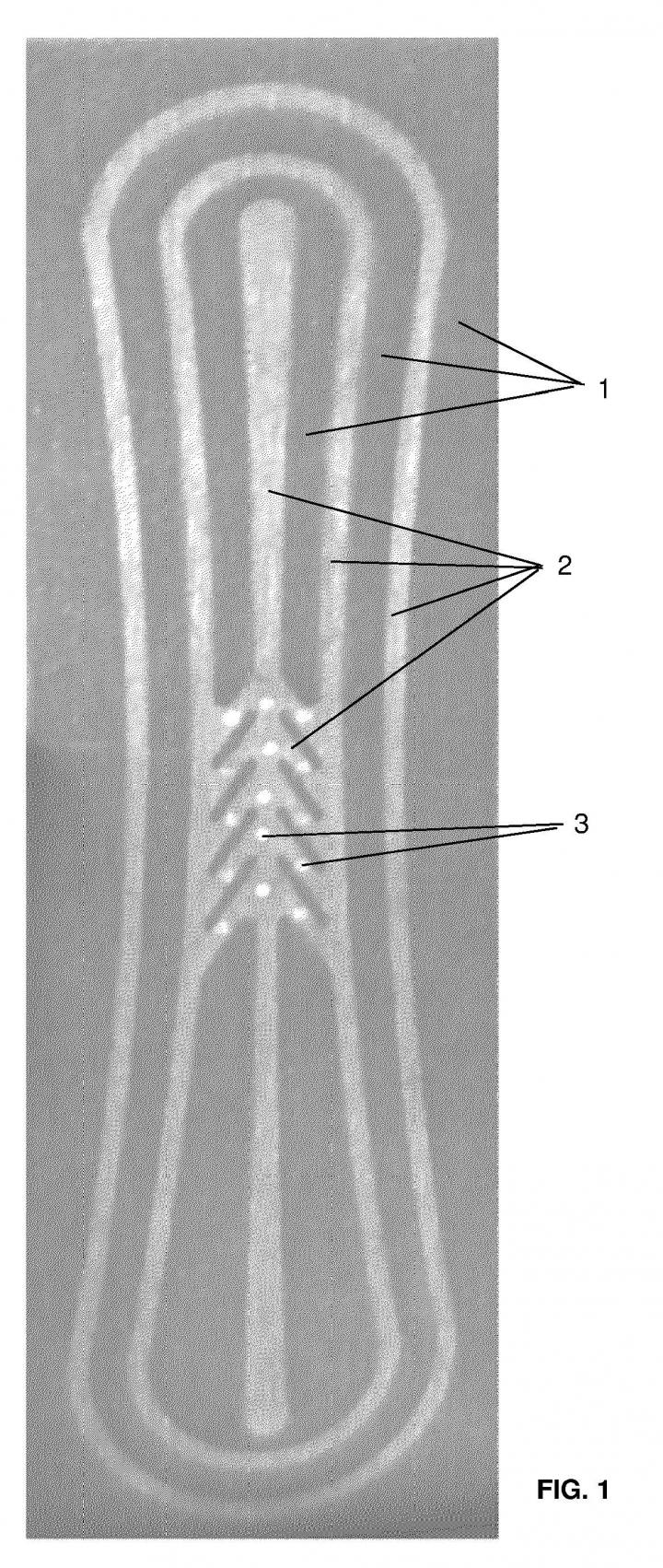

The profiled surface of the foam layer according to the present invention may be in any compressed, relief pattern or shaped design. However, certain shapes and designs are described below as being associated with particular technical advantages.

The profiled surface may comprise a pattern of connected or interconnected indentations (compressed portions) formed into said surface to provide one or more, such as a plurality, of raised portions (non-compressed portions or hills). The raised (non-compressed) portions may be discrete raised portions. A pattern of connected or interconnected indentations may comprise a first indentation formed into said surface in a first direction and a second indentation formed into said surface in a second direction that is different from the first direction. Optionally a third or even more indentations may be formed into said surface in a third or other directions that are different from the first direction and the second direction. The various indentations may meet or intersect to create the interconnection. The indentations may be in the form of a pattern of connected indentations being non-linear, for example non-linear across their entire length. The pattern of connected indentations may cover more than 10%, 20%, 30%, 40% or 50% of the foam layer surface.

The indented compressed portions may have a width of greater than 1 mm, preferably greater than 2 mm. An advantage of this configuration is that liquids can more effectively and quickly be distributed over the foam layer and also to account for deformation of the foam upon swelling in wet conditions so as to retain its general overall shape and limit excess deformation that could lead to discomfort when worn by a subject.

The openings may be of any shape, e.g. circular, ellipsoidal, rectangular, slit, slot, preferably circular. They are preferably present in the indented compressed portions to compensate for the reduced capability of penetration of liquid in these portions. Their maximal dimension, e.g. their diameter in case of circular openings, is advantageously equal or smaller that the width of the indented compressed portions. The openings are preferably present in the central portion of the absorbent core, close to the exudate inlet point, for a rapid intake of fluids towards the bottom surface of the foam layer and the further nonwoven layer joined to the bottom surface of the foam layer. There may be more than 3, 5, 8 or 10 and/or less than 30, 25, 20 or 18 openings.

Suitable top sheets may be manufactured from a wide range of materials including, but not limited to nonwoven materials, apertured formed thermoplastic films, apertured plastic films, and hydroformed thermoplastic films; reticulated thermoplastic films; thermoplastic scrims; and film/nonwoven laminates. Suitable nonwoven materials can be comprised of natural fibers (e.g., wood or cotton fibers), synthetic fibers (e.g., polymeric fibers, such as polyester, polypropylene fibers, and polyethylene, or polyvinylalcohol, starch base resins, nylon, and rayon fibers) or from a combination of natural and synthetic fibers. Apertured formed films and film/nonwoven laminates are generally preferred for the topsheet because they are pervious to liquids and, if properly apertured, have a reduced tendency to allow liquids to pass back through and rewet the wearer's skin. Films may also show better results in terms of run-off. Polyethylene (PE) films and laminates comprising a nonwoven and a PE film are most preferred.

Advantages

- In an embodiment of a sanitary napkin, the quantity of superabsorbent polymer particles may advantageously be between 20 and 50 gsm, preferably between 25 and 45 gsm.

- The herringbone or V-shaped design advantageously provides an in situ drainage system for fluid and/or exudate. The profiled surface may also comprise at least one, advantageously two, generally circular or elliptic indented compressed portion extending substantially around the central elongate indented compressed portion and optional additional elongate indented compressed portions.

- The product of the present invention overcomes the problems of prior art products, as it provides a fast acquisition of body exudates within the product and a good liquid retention capacity, by providing at the same time a combination of low acquisition time and low rewet.