Biofouling

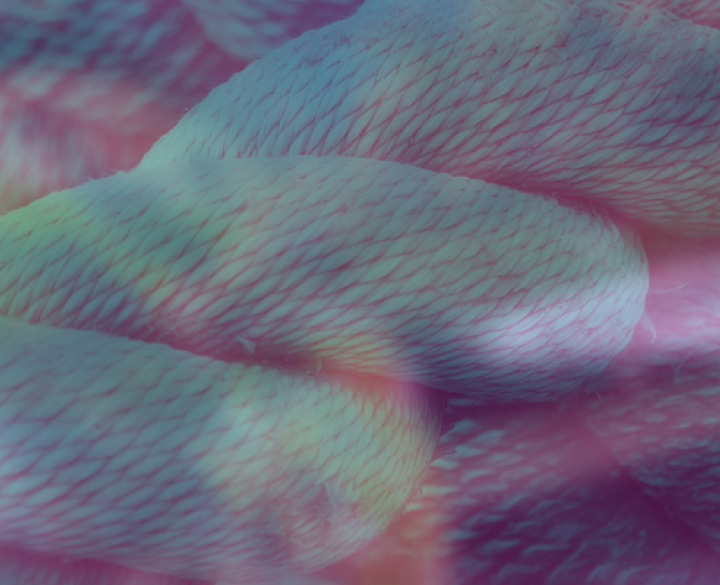

Some products spend most of their lifetime outdoors: from ship hulls, mooring lines, and fish farm nets to outdoor wall cladding and terrace tiles. These kinds of products are subject to the whims of nature. Over time, their surfaces accumulate microorganisms, algae or moss. This process, known as biofouling, degrades the surface material and negatively impacts product performance.

Coatings keep it clean!

Tackling biofouling is a costly endeavour. Therefore, companies prefer preventive measures, such as treating outdoor products with coatings to fend off fouling. Traditionally, these fouling restraining coatings were based on toxic metals such as tributyltin (banned since 2008) and copper.

A sustainable solution?

In their search for a sustainable and non-toxic coating technology, companies have been looking into bio-based coating agents for over a decade. Today, such agents are available, but their commercial use is limited due to poor performance.

Abundant and adaptable

The intercluster project FResCo seeks to overcome these limitations by developing novel bio-based coating agents that can be used commercially in both marine and terrestrial applications. To this end, the project will investigate several suitable biopolymers such as chitin, chitosan, pectin and alginate. These biopolymers are abundantly available on our planet. However, the commercial availability of these biopolymers is rather limited and they should be altered to meet specific coating requirements. Modification and formulation of these biopolymers, and finally their applications represent the core focus of FResCo.

Looking ahead

By the end of the project, industries will have access to novel, non-toxic and bio-based fouling restraining agents that can be used commercially in both marine and terrestrial applications. This way, FResCo will support companies in making their products more durable, and thus more sustainable.

Partners

FResCo is an innovation project supported by Catalisti, Blue Cluster and Flanders Innovation & Entrepreneurship (VLAIO). The project spans the full value chain of fouling restraining coatings: starting from a biopolymer platform (ChemStream), a coating developer (I-Coats), to two end-users of coated materials (Bexco for mooring ropes and Deceuninck for wood-plastic composites).

Research partner Centexbel brings in its expertise in bio-based coatings.