Avec le soutien du Fonds européen de développement régional

Met steun van het Europees Fonds voor Regionale Ontwikkeling

More information

Context

The RECY-COMPOSITE project addresses the problems related to the mechanical and chemical recycling of composite materials (pyrolysis and solvolysis) and the energy recovery if recycling is not possible. The applied research is conducted on the production waste stream of thermo-curing composites and of end-of-life in thermo-curing and thermoplastic composite materials.

Aim

This innovative global approach is facilitated by uniting the complementary competences of five RECY-COMPOSITE partners, who will create a genuine added value in cross-border developments.

In the perspective of an industrial shift, the economic aspect (material and transformation costs) will be reckoned with, as well as with the LCA during the selection of the technology for industrial applications.

The partners will focus on specialised chemical processing to offer products with an added value instead of mere fillers for plastics.

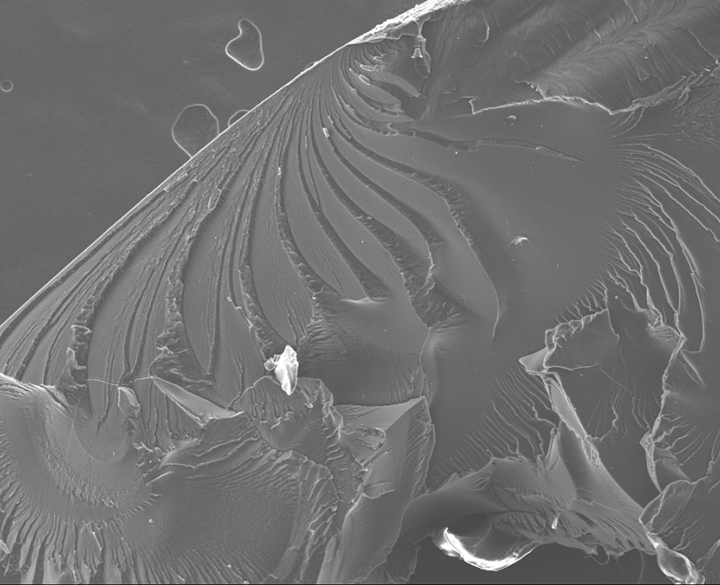

The first phase of composite recycling is the fragmentation of the material by for example cryogen moulding by cooling the material with liquid nitrogen. The different components can then be separated (classification, dimensions, electrostatic, density…) to create a specific valorisation and the highest added value.

New recycling techniques such as solvolysis and pyrolysis are further developed and evaluated. The best fibre recovery techniques will be selected to upgrade the material.

Another innovative route is chemical recycling by which the materials are converted through carbonisation and used as raw materials in fireproof swelling agents. Different formulations will be examined in respect of their fire retardant properties and compared to the valid standardisation to rapidly place them on the market. The markets that will be examined are interior applications in trains and airplanes and construction products.

The collection of the complementary competences will have a maximum impact on the industry located in the cross-border region. The exchanges of knowledge and best practices will stimulate the development of new products from recycled materials. The consortium will also collaborate in a constructive manner with the regional structures, competence pools and clusters to optimally support the composite recycling sector.

The cross-region activities in the field of applied sciences, awareness campaigns, dissemination, guidance and support are included in the project and will promote the collaboration between the companies and research institutes to create an optimal technology transfer across the borders.

Partners

- Certech

- Crepim

- Centexbel-VKC

- CTP

- IMT Lille Douai - Armine

The Recy-composite partners are located in each of the three area of the France-Wallonie-Vlaanderen territory. They have complementary skills adapted to their respective industrial base. Beyond a recognized knowledge of plastics processes, those centers have a useful expertise into waste processing and sorting, thermochemical recycling processes, fire resistance, formulation and shaping of composite materials. Each center, with its own specificity, brings a real added value to the common development of the cross-border actions.

Budget

Total: 3 179 531,30 EUR

European Regional Development Fund: 1 589 765,63 EUR