In Europe, the standard EN 388 is used to regulate protection classes of cut restistant safety gloves. To achieve a high level of cut protection, several technical materials – known as high performance fibres – are used.

Testing procedures and product classifications are adapted to reckon with this continuous process of product and material developments.

Rotating cut resistance test : Coupe test

The samples are cut with a counter rotating blade with an alternating movement and specific load.

- sampling area: palm of the glove

- linear movement of a rotating knife over the sample until the fabric is cut through

- introduction of reference material (typically cotton)

- altenration of sample and reference material until at least 5 results are registered

- loss of sharpness of te knife is compensated by cutting the reference material before and after the sample

- cut resistance is determined by the number of cycles needed to cut trhough the sample related to the reference material

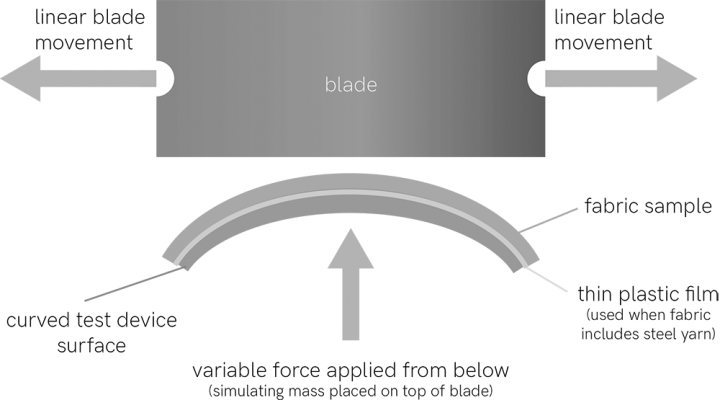

Linear cut resistance test (TDM-100) method

The ISO 13997 cut resistance test has been added to the revised standard EN 388 to reckon with the novel materials (high performance fibres) for protective gloves.

- a fabric sample is fixed on a curved testing device and a force from beneath is applied

- the knife sharpness is calibrated after each completed cycle or when the knife has cut through the sample

- the cut-through is established when an electric contact is observed between the knife and the curved testing device

- if the sample contains any metallic yarns, a plastic film is placed between the testing device and the fabric to prevent electric contact initiated by the fabric

- the sample is submitted to a minimum of 20 cutting movements applied with variable forces

- the distance that is covered to cut through the material is measured

- the data are used to establish the force that is needed to cut through the fabric

Marking

Send your samples to

Centexbel - Physical Lab

Technologiepark 70

9052 Gent-Zwijnaarde

Belgium

+32 9 220 41 51

gent@centexbel.be