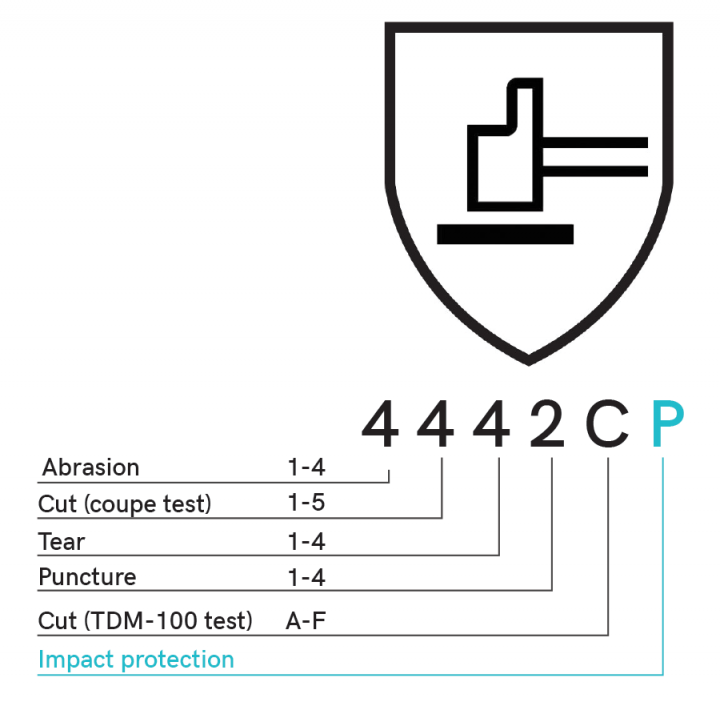

In a matter of seconds, a situation can escalate from a small bump on the hand to a life-altering injury. To meet the newest materials used in the manufacturing of protective gloves, the range of standard test methods has been updated (EN 388:2016) and extended to include the impact test as described in EN 13594, to enable workers to make an informed decision about the performance levels of the gloves they need.

More transparent information leads to safer work environments and fewer injuries.

Principle

The impact protection on the back of the hand of protective gloves is tested according to EN 388:2016 that includes an impact resistance test in accordance with clause 6.9 of EN 13594.

The marking will include a ‘P’ to indicate the glove has passed the impact test.

The impact test will only be included for gloves that claim specific impact-resistant properties.

Testing procedure

The impact test shall be performed in a way that the centre of the falling weight hits directly the zone where the glove covers the centre of one of the four knuckles.

Number of samples and tests:

- 4 sample gloves, each one to be hit once;

- as far as possible the 4 sample gloves shall be of different sizes;

- each one out of the 4 single tests shall be carried out on a different knuckle.

Test spot on gloves without a visible impact protection element:

The glove sample shall be donned by an assessor with appropriate hand size who shall then firmly grip a cylindrical bar of diameter 32 mm ± 5 mm and length ≥ 120 mm and the position of the most prominent points of the knuckles to be tested shall be marked on the back of the glove. The same procedure shall be repeated with 2 other assessors. The triangle between the 3 marked points on the chosen knuckle will be the area to be placed onto the centre of the testing anvil.

Test spot on gloves with a visible impact protection element:

Once the correct position of the protection element has been confirmed, the most prominent part of the shield over the chosen knuckle shall be marked as the point which will have to be placed onto the centre of the anvil.

The impact test

- A piece of soft split leather (0,8 – 1,0 mm, e.g. chamois leather) is placed over the 100 mm radius dome of the anvil. The sample is positioned with the previously marked impact point onto the centre of the dome.

- A 2,5 kg striker with a flat impactor face is then raised to a height that will provide the required impact energy of 5 J ± 0,1 J when touching the test piece.

- After releasing the impactor the peak force detected by the load cell or other sensor beneath the anvil is recorded.

- It is also checked and recorded whether the soft split leather is torn or holed.

- This test is repeated four times in each impact protection area that has been sampled from four different gloves.

A 2,5 kg striker with a flat impactor face is raised to a height that will provide the required impact energy of 5 J ± 0,1 J when touching the test piece.

After releasing the impactor, the peak force is recorded.

Test results

Impact protection is one of the requirements of protective gloves according to EN 388:2016

To pass the test, the transmitted force shall be less than or equal to 7 kN (kilonewton) and no result shall be greater than 9 kN. When a glove has passed the test, it means that the protective material successfully and safely dissipates the forces away from back of the hand.

Marking

When the requirements are fulfilled by the gloves, the marking code “P” is added after the five performance levels number.

Please note that the impact test can also be used to test the impact resistance of knee protectors!

Send your samples to

Centexbel - Physical lab

Technologiepark 70

9052 Gent-Zwijnaarde

Belgium

+32 9 220 41 51

gent@centexbel.be