Centexbel Grâce-Hollogne specializes in circular textiles and plastics, with a strong emphasis on sorting and recycling.

Research

To ensure effective recycling, it is crucial to properly sort the incoming feed before processing. We actively participate in various projects aimed at developing sorting systems and evaluating the composition of post-consumer textile flows.

PLASTICE: The aim of this European project is to develop technologies that can effectively incorporate plastic waste into the circular economy. One of the key technologies being developed focuses on recycling cotton/polyester post-consumer textiles.

In this regard, Centexbel, in collaboration with De Kringwinkel, is responsible for upgrading their sorting line and sorting several tons of post-consumer textiles. As part of the PLASTICE project, Centexbel has thoroughly researched the available commercial solutions in the market and has created a reference library of textiles with known compositions. This library serves as a valuable resource for testing and selecting the most efficient sorting system. Additionally, Centexbel has the capability to accurately determine the composition of textiles, ensuring the purity of the sorted flow. This comprehensive approach ensures the successful integration of plastic waste into the circular economy.

DESEPTEX is a project funded by Wallonia that aims to develop a process for detecting and automatically removing trims (such as rippers, buttons, and prints) from post-consumer textiles.

The initial step involves distinguishing between textile and non-textile materials. To achieve this, the textiles will undergo scanning using both visual and infrared cameras. Subsequently, an algorithm developed specifically for this project will be utilized to identify and segment the various components.

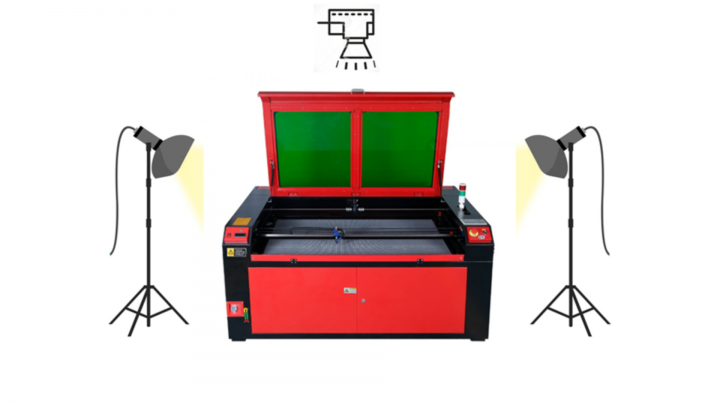

In the second phase, laser cutting, an industrial technique commonly employed in the textile industry, will be employed to separate the trims from the textiles. Centexbel will construct a prototype for DeSepTex, which will be made available for trials.

Companies and organizations interested in joining our steering committee are encouraged to participate.

CISUFLO: The primary objective of this European initiative is to establish a comprehensive framework for the production of sustainable and circular floor coverings, including carpets, resilient floor coverings, and laminates.

The ultimate goal is to minimize the overall environmental impact of this industry.

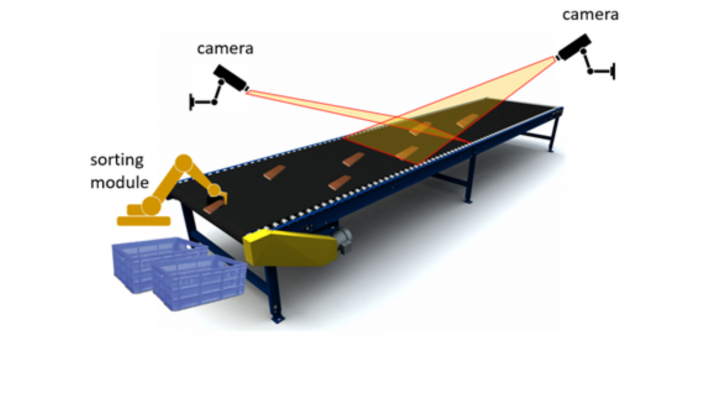

As part of the CISUFLO project, a pioneering sorting and identification facility will be implemented at Centexbel in collaboration with Rina, an Italian organization. This sorting line comprises various components such as a conveyor belt, a visual camera for object localization, a near infrared detector to determine object composition, a QR code and RFID reader, and a vacuum gripper system for effective sorting.

Initially, the focus will be on sorting floor coverings, but there is potential for expansion to include other materials in the future.

REPREC: This Walloon initiative aims to investigate and develop recycling techniques for unimpregnated carbon fibers and carbon fiber prepreg that is pre-impregnated with polymer resin.

The primary goal of this project is to design, test, and assess a recycling method that allows for the incorporation of these scrap materials into industrial manufacturing processes using the patchwork technique.

The focus is on applications that have high added value but lower mechanical performance compared to aerospace applications.

In cases where the polymerized scraps cannot be reused in the patchwork structure, a chemical recycling method will be employed.

Additionally, the project emphasizes waste collection, documentation, raising awareness among producers about the new management approach, and conducting a life cycle assessment.

Circular Wallonia

Centexbel is the coordinating body for the "Textiles" Task Force, which was established by the Walloon Region as part of Wallonia's recovery plan to promote economic development through the circular economy.

Within this framework, Centexbel has been assigned various responsibilities.

Our first task is to sort textile waste based on its composition, using user-friendly and easily accessible technology such as a near infrared spectrometer. In order to carry out this case study, Centexbel has subcontracted the sorting and collection sector through a public contract.

The second objective is to remove lint and other foreign objects from the waste, which could hinder the recycling process of textiles. The aim is to develop industrial solutions by leveraging the skills of employees and available technology. To achieve this, unloading lines will be established in sorting centers using a field research approach. Integrating this new activity into a sorting center necessitates adjustments to processes, staff training, workspace modifications, logistics, and other related aspects.

Equipment

Centexbel Grâce-Hollogne is also involved in recycling textiles, plastics and composites.

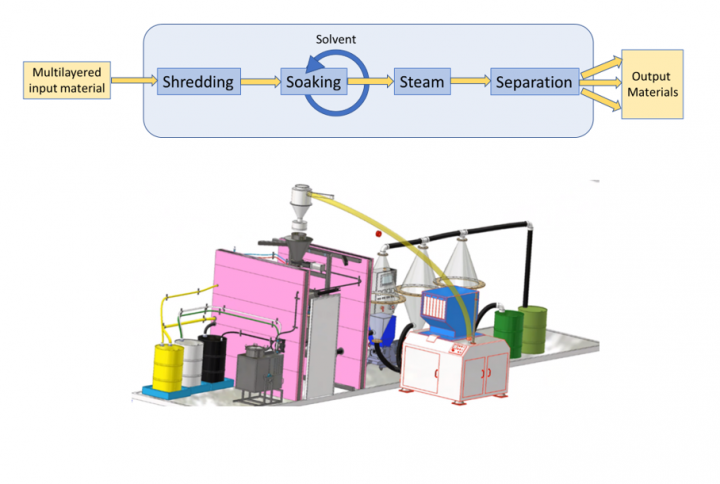

Initially, the POLYSEP technology was developed specifically for PET/PVC materials. However, ongoing investigations are now focused on expanding the range of materials that can be treated using this method.

- The process begins by shredding the input material, which is then soaked in a solvent. This causes the PVC fraction to swell.

- Next, steam is injected, triggering a rapid evaporation of the solvent. As a result, the PVC coating separates from the PET substrate. To obtain different individual streams, the materials can be separated using conventional methods like zig zag air separation.

- The solvent is recovered through a distillation process and reused in a closed loop system.

This equipment is now available at Centexbel Grâce-Hollogne.

PolySep is a patented batch process for the separation of multi-layered materials (EP3504037A1)