Applicant: SEYNTEX

Inventors: Filip Ghekiere, Pol Speleers

Patent application number: WO2022/228924

The problem

Zippers, buttons or hook-and-loop systems are used to close garments. For some applications, however, the closure of a textile product is more critical and has more requirements than joining two textile surfaces.

For firemen jackets, the closure of the jacket at the front side of the jacket must be reliable, watertight and fire resistant. A simple zipper system does not suffice. A strip of textile is used to cover the zipper, to couple the left and right front part of the jacket one to the other. The strip of textile, once provided in front of the zipper system, may be held in place by, for instance, a hook-and-loop system, better known as a Velcro system. Closing and keeping the closure closed ensure the jacket fulfils its function of protective wear also along the zipper part. If for whatever reason the closure is not correctly closed or kept close, the fireman's safety is put in danger.

For soldiers and policemen jackets, in particularly for soldiers of special forces, it might be deadly important that a textile closure, e.g. a closure of a pocket, opens and closes without any sound. A sound may give away information on their presence. However, in order to keep the stored equipment in a pocket of such jacket or battle dress, the pocket needs to be kept close with certainty at all times.

Therefore, there is a need for a textile closure which gives a.o. certainty as to its closed position at all times, and/or which is silent to open and/or close. The closure is to guarantee a closed position and/or should return to a closed position without intervention of a person.

The solution

The present invention generally relates to closures of textile products, such as garment, e.g. jackets, in particular protective garment.

The invention further relates to the use of the closures in garments, particularly protective garment, such as jackets and double jacket systems.

The invention relates in particular to suits and jackets for firemen, soldiers, policemen and persons working in potentially hazardous environments such as on chemical and petrochemical plants.

The present invention aims to provide a closure for a textile product which overcomes one or more drawbacks of the prior art. According to a first aspect of the invention, a closure of a textile product is provided.

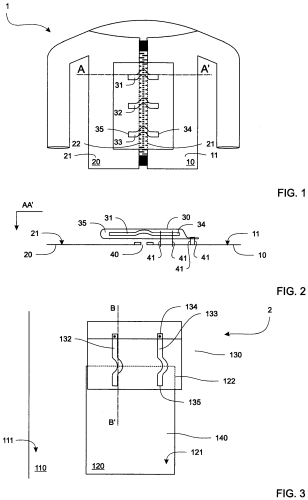

The textile product comprises a first and a second textile surface, both the first and the second textile surface having a first side facing the same direction. The second textile surface has an edge. A first textile strip is coupled to the first side of the first textile surface and extends up to or beyond the edge of the second textile surface over the first side of the second textile surface. The first textile strip is provided with at least one resilient means holding the first textile strip in front of, possibly against the first side of the second textile surface.

Preferably, the at least one resilient means presses the first textile strip to the first side of the second textile surface. It means that, when the first textile strip contacts the first side of the second textile surface, the resilient means is not in a stable position and still exercises a force to the first side of the second textile surface.

The first side may typically be an outer side of a textile product in use, such as the outer side of a garment or a functional textile product, e.g. a door or valve from textile material, e.g. in a tent or shelter surface or alike. The textile surfaces both have also a second side, being typically the inner side of the textile product in use.

Between the two edges, a space may be provided which space needs to be bridged by the textile strips. The two edges of the first and second textile surface may be mutually parallel, even being equidistant one to the other along part or the whole of the length of the edges.

The closure further may comprise a second textile strip coupled to the first side of the second textile surface and extending under the first textile strip beyond the edge of the second and first textile surface. The second textile strip may extend under or over the first side of the first textile surface.

The use of a spring, in particular a torsion spring or bistable spring, is preferred as it is fairly easy to install in the textile product and is reliable as to the force it provides on the first side of the second textile surface by the first textile strip.

This bistable spring may be a bistable hinge and may comprise a metal or polymer ribbon. This ribbon may be a bistable spring band or bistable spring blade. The bistable spring may, at its both sides, be provided with a polymer or metal plate, enlarging the dimension of the bistable spring.

The use of bistable springs has the advantage that the first textile strip can be pressed against the first side of the second textile surface in a first of its two stable positions, preferably its stable position, thereby possibly closing a gap defined by the edge of the second textile surface. In its second position, possibly being its metastable position, the first textile strip is not pressed against the first side of the second textile surface but can leave the edge of the second textile surface accessible. Changing the bistable spring from the first to the second position can be done easily by moving the bistable spring from one of the two positions towards the second of its two positions. Once the bistable spring, being in a given open or closed position, is moved sufficiently far, i.e. one has exercised a sufficiently large amount of work to the bistable spring, the bistable spring will further change to the other position by itself. If no such amount of work is applied, the bistable spring will return to its staring position if the force is taken away. As such, these embodiments of the invention provide closures which have a certitude to be in either the open or closed position.

The number and dimension of the resilient means depends largely on the properties, like the weight, of the first textile strip which is to be brought in front of the second textile. The distance between adjacent resilient means may e.g. be in the range of 10 to 60 cm centre-to-centre, such as every 15 or 35 cm centre-to-centre.

Advantages

The closure according to the invention has the advantage that it may close very silently and smoothly.

The use of bistable springs has the advantage that the first textile strip can be pressed against the first side of the second textile surface in a first of its two stable positions, preferably its stable position, thereby possibly closing a gap defined by the edge of the second textile surface.

Therefore, there is a need for a textile closure which also gives certainty as to its closed position at all times, and/or which is silent to open and/or close.