Applicant: Elektrotechniek Verno

Inventor: NOENS PHILIPPE

Patent application number: EP3960210

Problem

The invention came into being during a crisis in which there was a shortage of high-quality face masks, when it quickly became apparent that a face mask can only be used safely for a short period of time, after which it must be replaced. The primary purpose of a face mask is to protect the wearer and/or the environment against transmission of microorganisms and viruses. For this purpose the face mask forms a barrier to microorganisms and viruses. This primary purpose of the face mask is only achieved when the face mask is free of biological contamination. Biological contamination builds up due to use of the face mask, after which the face mask must be replaced.

High-quality face masks are not intended to be disposed of after a single use, but to be used repeatedly. For this purpose, a good cleaning is necessary. The cleaning has the primary object of removing the biological contamination from the face mask. Biological contamination is difficult to detect, making it difficult to check whether a face mask is free of contamination. Incomplete or insufficient cleaning can therefore create a false sense of security and should be avoided.

It must be possible to guarantee the quality of the cleaning, which is directly related to the degree to which a face mask has been cleaned fully and sufficiently, over the whole surface of the face mask. In the event that a small part of the surface of the face mask was cleaned to a lesser standard, biological contaminations may still be present on the face mask and contaminate its wearer or a bystander. Inferior cleaning of only a small part of the surface therefore has negative consequences for the whole face mask.

Solution

The invention provides a device and method wherein the quality of cleaning of the face mask can be improved.

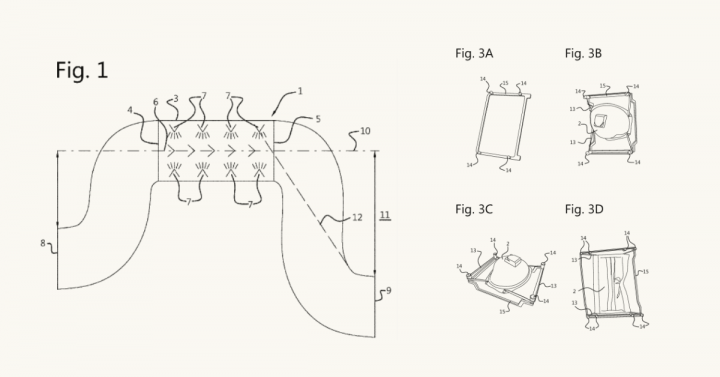

The device comprises a housing with an inlet and an outlet opening, wherein a throughfeed mechanism is provided, wherein cleaning means are provided in the housing all around the throughfeed path in a manner such that the cleaning has an effect from substantially all perpendicular directions of incidence to the throughfeed path.

Because the cleaning means are primarily configured to clean or remove biological contaminations such as microorganisms and viruses, they are harmful to humans and animals. Throughfeed means are provided which carry the face masks from a supply opening, through the housing, to a discharge opening. The supply opening and the discharge opening here lie at a distance from the central axis of the throughfeed path. In other words, the object is for the cleaning means to be able to reach neither the supply opening nor the discharge opening.

The cleaning means preferably comprises at least one UV-C lamp. A UV-C lamp is known as biological cleaning means. Depending on the dose and operating intensity a UV-C lamp will kill almost all microorganisms and viruses so that a biological cleaning is achieved.

The at least one UV-C lamp is preferably mounted movably in the housing such that the UV-C lamp is movable all around the central axis so as to change an angle of incidence of radiation of the UV-C lamp onto the throughfeed path. The N UV-C lamps are preferably mounted on a structure which is bearing-mounted rotatably in the housing, which structure is provided for reciprocal rotation about the central axis between two end positions lying at a mutual angular intermediate distance of at least 360 degrees divided by N.

The housing also comprises a sensor for measuring an operating intensity of the cleaning means, and is operatively coupled to the throughfeed mechanism. By providing a sensor and directly measuring the action of the cleaning means it can be guaranteed that the face masks have also been subjected to a predetermined dose of the cleaning means. Depending on the operating intensity of the cleaning means, the throughfeed speed can here be adjusted in order to guarantee that each face mask has received a minimal cleaning. This makes it possible to offer a quality guarantee. The sensor also allows immediate detection of incorrect operation or malfunction of a cleaning means.