Applicant: HYLER

Inventor: Niels Baert

Patent application number: WO2023/002345 A1

The problem

Over time, many different machines have been developed to pick (harvest) and process fibre plants. Some picking machines are suited to pick relatively short fibre plants (such as flax), others are made for relatively long fibre plants (such as hemp). These picking machines lay the picked fibre plants flat on the ground in rows (swathes) in order to be retted. So-called turners will pick them up and turn them over.

Since fibre length and plant composition may differ, each processing step and each fibre plant requires a separate processing machine.

Useful components of fibre plants are fibres, wood-like parts and seed. The seed is located in the top portion or the Cannabidiol (CBD). Some picking machines will pick, collect, and process the fibre plants as a whole, in order to separate the seed from the fibres and wood-like parts. A drawback of these machines is that the fibre plants are then particularly used to extract seed, the other components such as fibres and wood-like parts do not undergo a retting process and are thereby less useful for certain applications.

The above-described picking machines place the picked fibre plants flat on the ground (in swathes) to undergo a retting process on the ground. A drawback of these picking machines is that the seed on the fibre plants placed on the ground is lost.

There is a need for a processing machine and a method to process fibre plants where these and other drawbacks are reduced.

The solution

The present invention relates to a processing machine for fibre plants, such as hemp or flax, and to a method for processing fibre plants with such a processing machine.

The processing machine comprises:

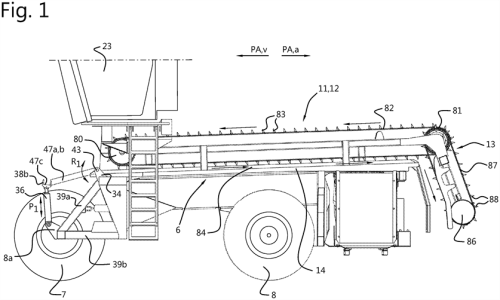

- a self-propelling vehicle; comprising a vehicle chassis with arranged thereon a number of wheels and a drive motor for driving at least one of the wheels, wherein the vehicle chassis is provided with at least one fibre plant conveyor which is configured to transport at least parts of the fibre plants from a first outer end of the vehicle chassis to an opposite, second outer second end, and with at least one delivering unit provided at or close to the second outer end and configured to deliver and place on the ground surface the fibre plants coming from the at least one conveyor;

- a seed part removing unit which is mounted on the self-propelling vehicle and is configured to remove seed parts (such as bolls) from the fibre plants to be picked;

- a picking unit which is mounted on the vehicle and is configured to pick fibre plants from which seed parts have been removed, wherein the picking unit is further configured to transport the picked fibre plants to the conveyor of the self-propelling vehicle. The seed part removing unit can for instance be a stripper for stripping the seed parts from the fibre plants.

It is another object to provide a processing machine which is suitable for altemataly performing different combinations of processing operations, particularly picking, placing on the ground and deseeding of fibre plants. It is another object to provide a processing machine which is suitable for processing fibre plants of different lengths, particularly flax and hemp.

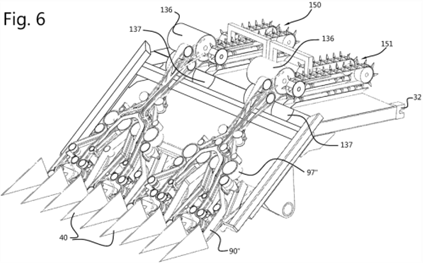

The processing machine is preferably suitable for use in a method wherein picking and deseeding of fibre plants are combined in a less objectionable manner. The processing machine should further be suitable to be able to place the fibre plants onto the ground in at least two swathes adjacently of each other when processing relatively long fibre plants.

Advantages

A dosing unit makes it possible to discharge a desired quantity of seed parts within a desired period of time in controlled manner.

The use of a flexible hose 502 has the advantage that placing of the removing unit 300 relative to the other components of processing machine 1 need not be very precise, so that it need not be set beforehand and the setting could even still be adjusted during use.

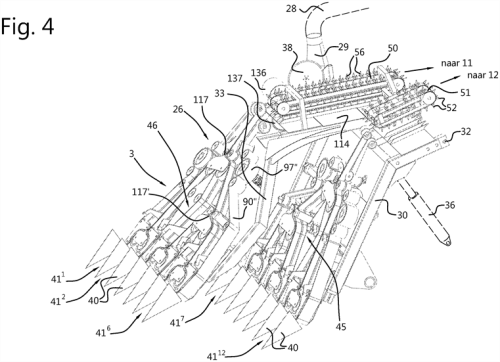

Their object is to make it possible to be able, when the vehicle and the picking unit 3 mounted thereon are advanced, to push the hemp plants (h) to the side and guide them into a number of, in figure 4 six per hemp picking unit (although this can also be a greater or smaller number in other embodiments), passages 411 16 for the upper hemp picking element 26 and passages 417-4112 for the lower hemp picking element 25, all configured to receive and grip the hemp plants.

The shown construction is particularly suitable for guiding and clamping seed parts, particularly the relatively large bolls which are difficult to deform and any material which may be attached thereto, and for removing these seed parts from the fibre plants by rotation of the rotatable removing element 220, particularly by scraping, cutting and/or ripping them off.