Recently we have witnessed a huge progress in understanding the nature of accidents due to electric arcs and the risks they pose to people working in their vicinity. Electricians are not only exposed to the risk of electrocution or physical shocks but also to the less obvious risk of thermal heat generated by the electric arc. The arc may indeed create a huge proportion of radial heat and - although invisible to the human eye - it may have severe and even lethal consequences by causing second to third degree burns of the human skin.

Therefore, methods have been developed to analyse the behaviour of clothing faced with electric arcs. However, these tests need the creation of a real-life arc, necessitating huge amounts of energy and the evacuation of possibly toxic fumes due to the flame-redartant products used in the textiles. Moreover, the test must be duplicated many times to obtain statistically significant results. The variation in obtained data may lead to sometimes slightly different conclusions on the efficiency of the garment.

To develop garments, the textile producer wishes to compare different technical solutions without having to resort each and every time to a "full scale" test method costing thousands of euros.

The aim of this study was to develop a new method to evaluate the level of protection offered by garments to electric arcs that is less expensive and burdensome, less energy consuming, and less toxic (in the event of inhaling fumes).

This "indirect method" can be incorporated into normalization if the correlation with the standard methods can be shown. Anyhow, the possibility to classify production processes without having to resort to direct methods will already be a major breakthrough for the manufacturers of this type of garments.

Result

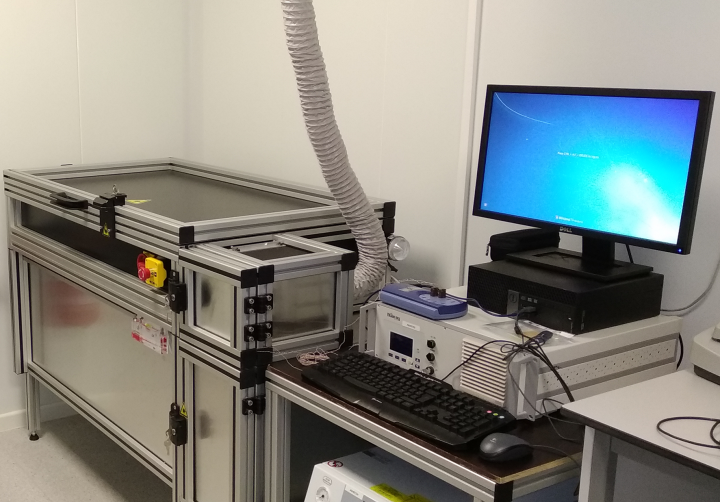

Centexbel developed a new method to evaluate the resistance of a protective garment against electric arcs

During the pre-standard study PN-ATPV, Centexbel developed a reproducible and easy to operate method based on the use of laser beams. We were able to prove a good correlation between the existing standard as well as a reliable repeatability.