To boost the production volume from recycled bituminous roofing materials, it is necessary to separate the historical presence of tars which today prevent their recycling because of their high content of polycyclic aromatic hydrocarbons (PAHs), which are harmful to human health (carcinogenic agent). These products present in the tar have been banned since 2010. As a result, roofing waste containing these tars can no longer be reused and is now sent directly to class I landfill, where it only adds unnecessarily to the mass of non-recycled products. In order to transform this waste into a new raw material that can be incorporated into roofing membrane production lines, a number of important technological challenges have to be solved.

Aim

Once identified, how can the tar-polluted fractions be separated and decontaminated? The answer to this question would enable the industry to partially free itself from the difficulties of supplying virgin bitumen to the European market.

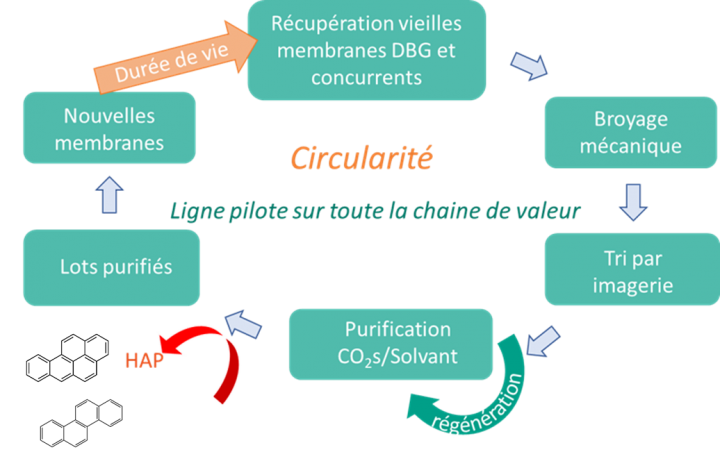

The BitumClean project therefore aims to develop an industrial process that would separate the bituminous tar fraction from discarded roofing membranes at low cost and without environmental consequences.

Note that only the PAH part of the tars will be extracted. This project is both a technological and environmental challenge. The solutions envisaged include the separation of the different fractions by solvent extraction with regeneration of the latter and/or by supercritical CO2. The expected results consist of the recovery of the separated noble fractions and the manufacture of new membranes from the decontaminated fraction.

A circularity-oriented project

Expected results

The benefits of this project are many and varied. From an environmental point of view, the recycling of this waste is a real added value and will make it possible to limit the use of petroleum products. In terms of image, this added value will be exploited by the participating companies to differentiate themselves from their competitors, who to date do not implement recycling, and to put a product with a positive environmental impact on the market.

It should be stressed that solvents and/or CO2 used to decontaminate end-of-life membranes will be recycled, which will further increase the environmental balance of the new membranes. Only tar will not be reused and converted into a product of interest in this project, although potential solutions do exist. A study may be devoted to this issue in the future, while the BitumClean project focuses on the feasibility of decontamination.

The creation of a new recycling channel for roofing membrane waste will lead to an increase the production volume. An increase in turnover is expected, both nationally and internationally, as the Scandinavian market has a strong demand for products with a positive ecological balance.

Positive effects on employment are also expected in the company to develop and operate the new recycling unit and ensure the increase in production volume.

Project partners

The BitumClean project is led by a consortium of 7 partners covering the entire value chain:

- a large company (Imperbel S.A.), project coordinator and manufacturer of roof waterproofing membranes

- an SME active in the manufacture of sorting control machines (Rovi-Tech)

- a university research laboratory with expertise in supercritical CO2 extraction (ULiège - NCE)

- a research centre labelled for its expertise in the field of textiles and solvent chemistry (Centexbel)

- an SME recognised for the development of solvent regenerators (Eco-Dec)

- an SME (Jadition) with recognised expertise in high-pressure gaseous media.

- a complete life cycle analysis of pre-existing and future waterproofing membranes will be carried out by ULiège-PEPs for each direction envisaged by the project.

All these partners are complementary in terms of know-how and expertise and have all the analytical tools, equipment and infrastructures enabling them to cover and carry out all aspects of the research.