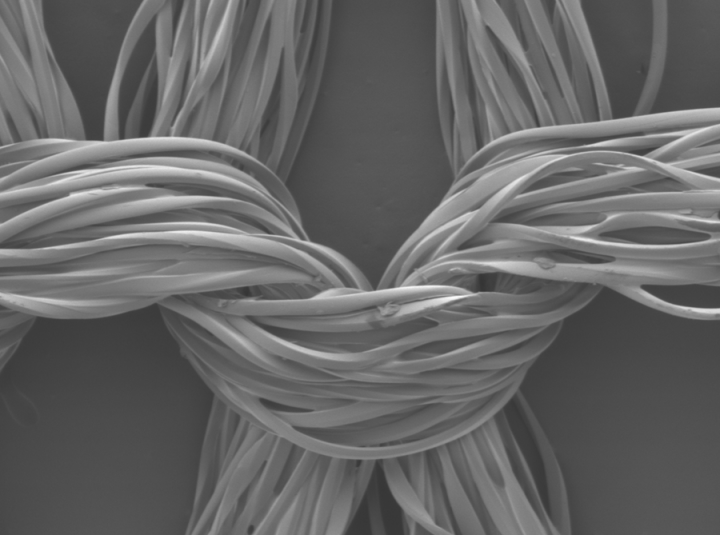

Verifying the manufacturing quality of advanced, high-strength textile materials and fibre reinforced polymers (FRP) is crucial, as it directly impacts the mechanical properties of the materials and the structural behaviour of its constituents.

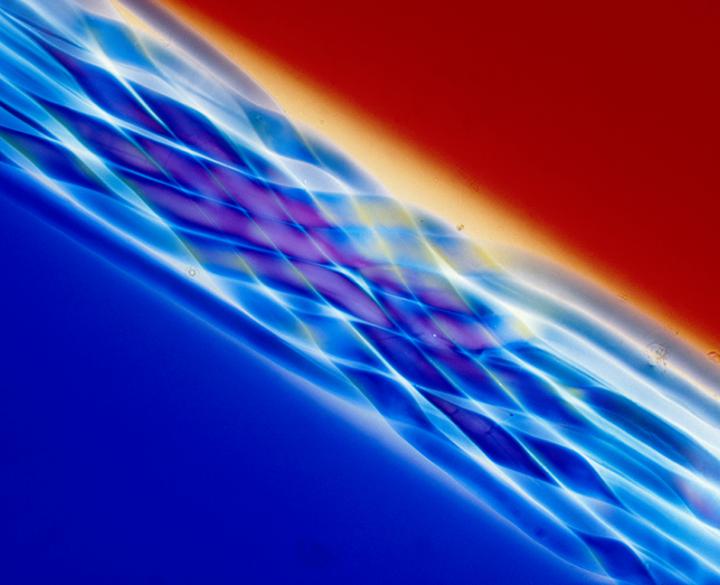

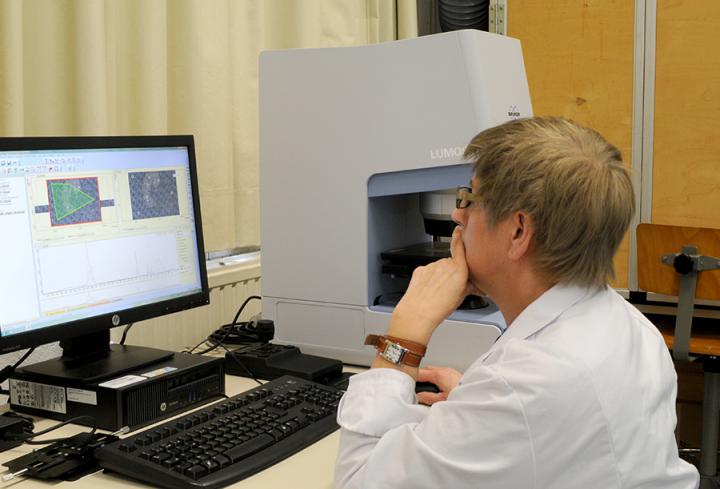

FT-IR microscopy

FT-IR microscopy is a well-established method for the chemical identification of particles or contaminants and for visualizing the distribution of certain substances in complex compounds. Due to the usage of modern focal plane array detectors, this technology has advanced to a new imaging technique during the last few years. It allows for the measurement of even large sample areas with a very high lateral resolution within a few minutes.

Scanning electron microscopy (SEM)

A scanning electron microscope (SEM) is a type of electron microscope that produces images of a sample by scanning the surface with a focused beam of electrons. The electrons interact with atoms in the sample, producing various signals that contain information about the sample's surface topography and composition. The electron beam is scanned in a raster scan pattern, and the beam's position is combined with the detected signal to produce an image. SEM can achieve resolution better than 1 nanometer. Specimens can be observed in high vacuum in conventional SEM, or in low vacuum or wet conditions in variable pressure or environmental SEM, and at a wide range of cryogenic or elevated temperatures with specialized instruments.

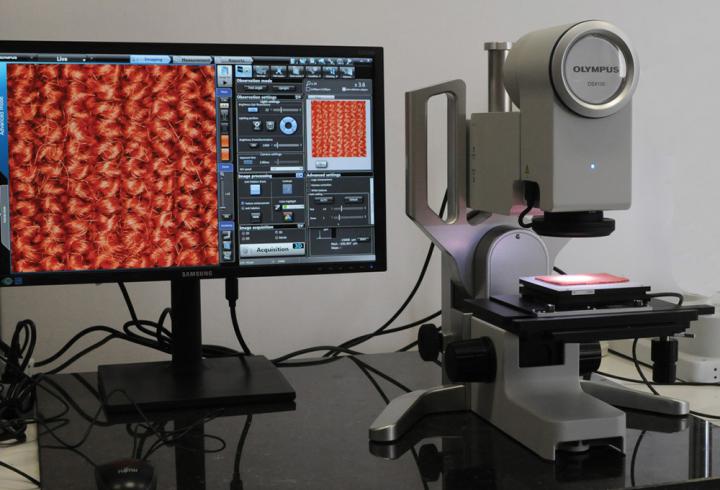

Olympus DSX 100

- Free angle wide zoom microscope with 16x zoom optics

- Opto-digital microscope combining advanced optics and digital technology. Instead of looking through eyepieces, everything is controlled by touch screen, which takes the operator through the process from inspection to measurement to analysis to final report.

Spectroscopy

Spectroscopy is a technique to determine the elemental composition of, and the presence of substances in materials, by means of the absorption and emission of light and other radiation by matter, as related to the dependence of these processes on the wavelength of the radiation.

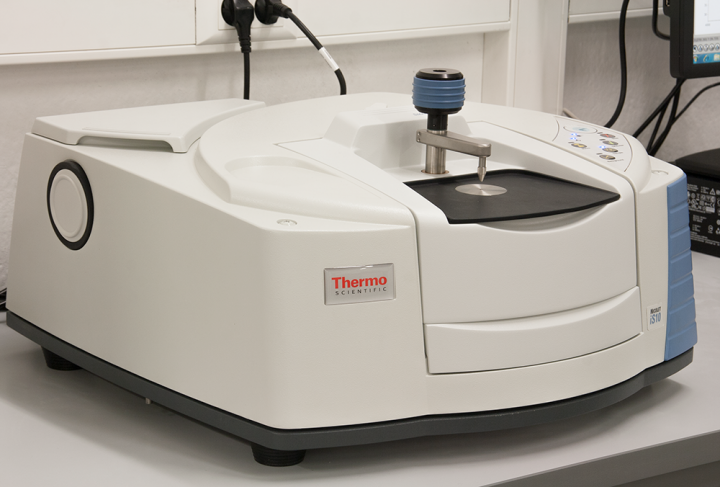

- FTIR or "Fourier transform infrared spectroscopy" is used to determine the polymer type, foreign substances in plastics and impurities in recycled matter.

- XRF spectroscopy is used to obtain information on the elemental composition of materials.

With the FTIR device, we perform almost two thousand analyses every year to detect the composition of organic matter.

Some examples:

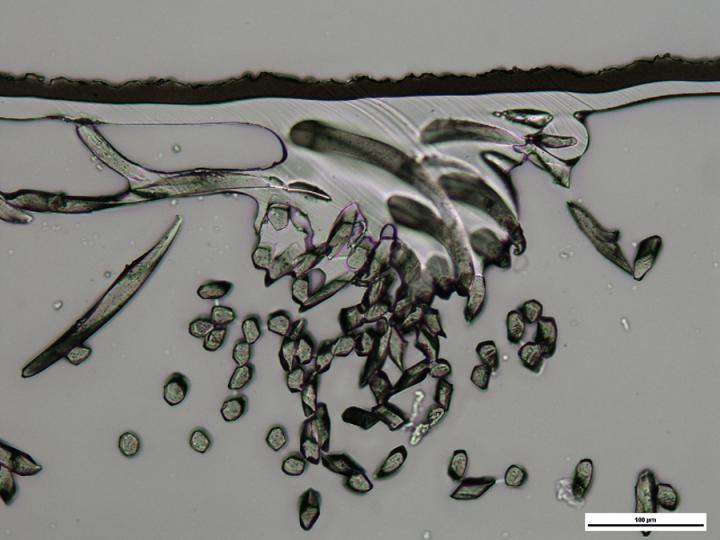

- fibre identification (ISO/TR 11827) where we can use FTIR to identify synthetic fibres.

- FTIR analysis checks the correct labelling of all parts of animal origin, such as pearl-like buttons or leather parts.

These analyses fit within the EU directive EU 1007/2011 on the correct labelling of fibre composition of textile products. Centexbel cooperates with the FPS Economy for market controls for this directive.

Moreover, an FTIR analysis is often used to solve customer problems:

- Problems in production, with quality or with the presence of foreign materials can often be solved by an FTIR analysis.

- Errors in the composition of coating pastes, in adhesives or binders or the presence of invisible top layers (e.g. acrylate) are some examples of material properties that we can detect via an FTIR analysis.

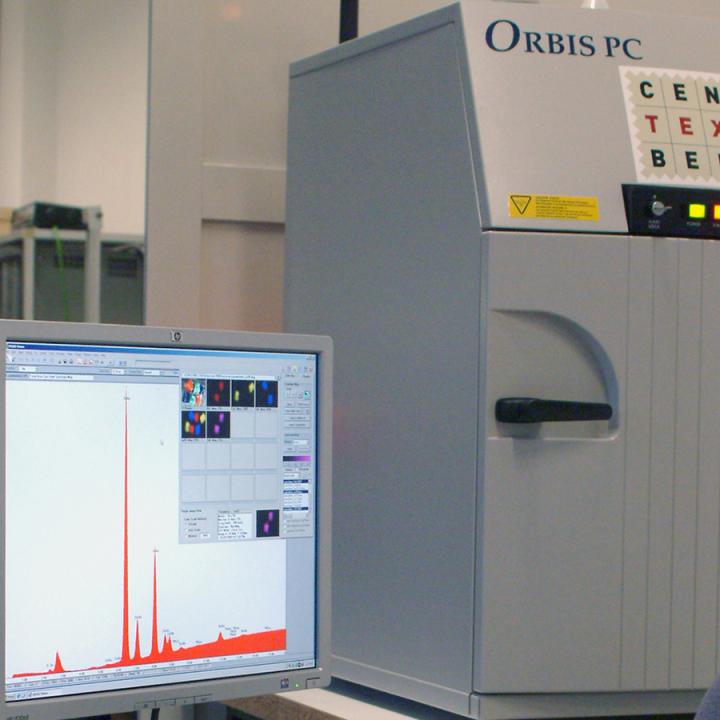

Edax Orbis PC microXRF

In addition to a rapid non-destructive semi-quantitative determination of elements, from sodium to uranium, the Edax Orbis PC microXRF includes several innovative analytic techniques :

- measurement with three optical lenses (30µm - 2mm) and several filters for Hazardous Substances (REACH)

- non-destructive flaw analyses with a measure spot of 30 µm (poly-capillary lens)

- element mapping (including bromine, chlorine, sulphur...) also on uneven surfaces

- generation of graphical overlaps

ICAP 6500 (inductive coupled plasma spectrometry - ICP)

This appliance allows Centexbel to perform type analyses of:

- conventional heavy metals (Pb, Cr, Ni, Sb, Cd…) in low concentrations in an acid-sweat matrix (high salt contents - for example in the framework of standard 100 by OEKO-TEX®)

- various concentrations of textile-proper elements (from functional additives to micro-pollution). To this end the ICP is equipped with an optical device for radial (high concentrations) and axial (micro) measurements

- critical elements: to this end, the ICP is equipped with a hydride modulus to determine Hg, As, Se… in a sufficiently sensitive manner

- quantitative screening of a large range of elements in mineralised textiles in a batch solution. This includes heavy metals as well as phosphor (fire retardant), silicon (anti-slippage), titan (matting) …

Atomised mineralisation of textiles in preparation of the ICP-measurement to determine the Ag (biocide), P (FR), Pb (CSPC) … content in textiles.

Combining µXRF and ICP

- the µXRF quickly provides semi-quantitative information on more elements than the ICP-system

- the µXRF + ICP combination allows us to determine exactly the content on parts of the samples selected by µXRF screening

Send your samples to

Centexbel - Chemical Lab

Technologiepark 70

9052 Gent-Zwijnaarde

Belgium

+32 9 220 41 51

gent@centexbel.be