Construction works must comply with the basic requirements specified in Annex I to the Construction Products Regulation (EU) No 305/2011 of the European Parliament and of the Council of 9 March 2011 laying down harmonised conditions for the marketing of construction products.

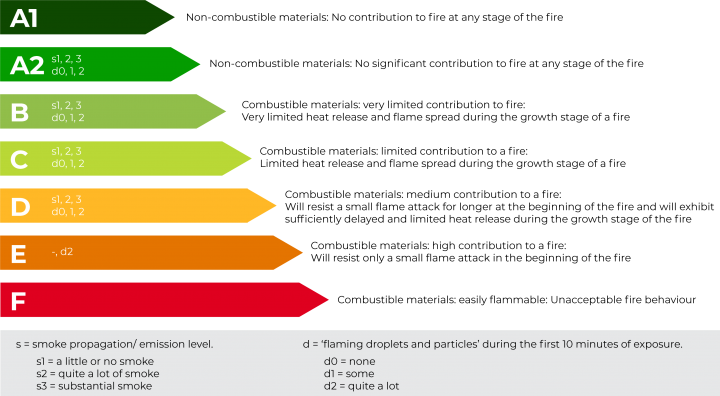

Basic requirement 2 specifies safety in case of fire. For all construction products placed on the European market, the fire performance must be classified according to the requirements of EN 13501-1: 2019 - Fire classification of construction products and building elements - Part 1: Classification with reaction to fire test data.

Member States remain competent to set the level of basic requirements in their territories for construction works. The product performance declared by the manufacturer thus allows engineers/authorities to verify that construction works built with these products will meet the basic requirements as applied in their Member State.

The potential contribution of a product to a fire depends not only on its intrinsic properties and thermal degradation, but also to a large extent on its end application in the construction. Therefore, it should be tested to simulate the end-use application.

End-use application as defined in EN13501-1 is the real application of a product, in relation to all aspects that affect its behaviour under different fire situations.

This end-use application mainly includes the following aspects:

- the orientation of the product;

- the position in relation to other adjacent products (substrate, fixing, etc.)

The type of fixing (screw, nail, type and amount of adhesive or other mechanical fasteners) of the specimen to the substrate plays a specific role in determining a particular fire classification.

The representative mounting conditions to be used for a given product are given in the relevant test methods or harmonised product specifications.

Radiant Panel test

The European Construction Products Regulation requires all European member states to use the radiant panel test method as part of the requirements needed to evaluate reaction to fire performance for all floor products, e.g. textile floor coverings, laminate, vinyl, cork, wood, rubber and plastic coverings and coatings. As mentioned earlier, for construction works, member states remain competent to set the level of basic requirements to be met on their territory.

In Belgium, the Royal Decree "Basic standards for the prevention of fire and explosion new buildings" of 07-12-2016 Annex 5/1 tables 1 to 4 specifies which fire classification is required in specific rooms, premises, escape routes and stairwells depending on building type, type of occupants and presence of fire detection.

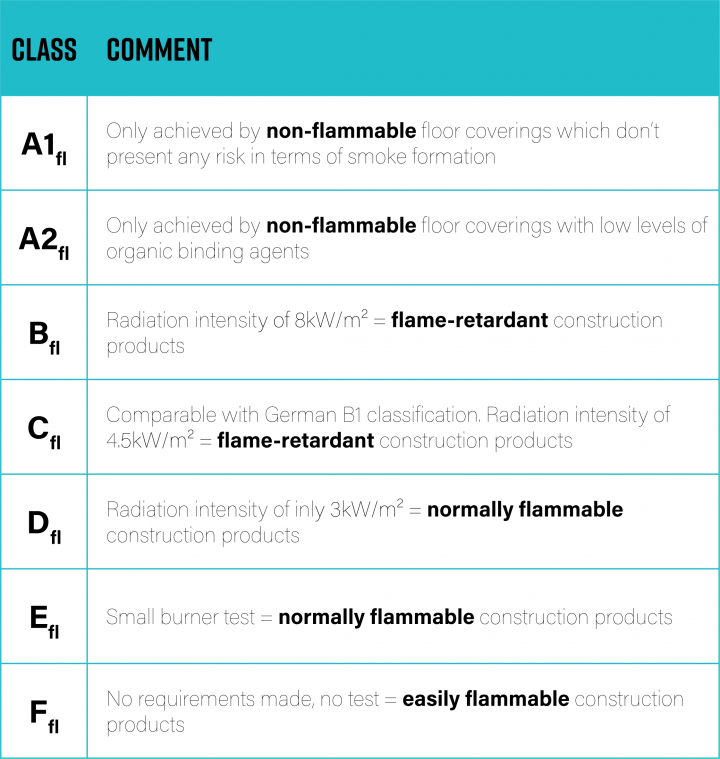

The fire reaction is the behaviour of a construction product that - through its own decomposition - fuels the fire to which it is exposed under specific conditions. The European Fire Reaction Classification distinguishes seven main classes (A1fl, A2fl, Bfl, Cfl, Dfl, Efl and Ffl), with the following addition: class s1 or s2 for smoke development.

EN ISO 9239-1 "Determination of the reaction to fire of floor products using a radiant heat source" is the main test method of the Euroclass system for floor products as defined in the European Construction Products Regulation. The test results are required for a classification Dfl - Bfl whether or not in combination with test results from EN ISO 11925-2.

Also within US legislation, the Radiant panel test forms an important part of the Classification. However, reference is not made to EN ISO 9239-1 but to ASTM E648, which differs from EN ISO 9239-1 on the following parameters:

- Sampling: 3 x test sample in production direction

- Conditioning of samples

- Air velocity speed during test 1.3 m/s instead of 2.5 m/s

- Time for initial ignition 300 sec instead of 120 sec.

- Extinguish time of pilot burner: 600 sec instead of 720 sec

- Test duration depends on extinguishing characteristics of carpet

- No smoke evaluation

The critical limits for radiant flux specified in the National Fire Protection Association (NFPA) 101 Life Safety Code for areas where automatic sprinkler protection is not provided are:

- Class I - minimum average of 0.45 watts per square centimetre

- Class II - minimum average of 0.22 watts per square centimetre

The higher level of critical radiant flow, Class I, is specified for healthcare facilities, assuming that occupants with limited mobility require a higher level of protection to escape.

The Class II level is specified for all other facilities where the higher level of protection is not required.

These requirements are general and the NFPA Life Safety Code or local codes should be consulted for more specific guidance. It is important to understand that the floor radiant panel applies only to carpet installed in hallways and not to room or open space installations. Carpet installed in rooms and all locations other than corridors falls under the "pill test".

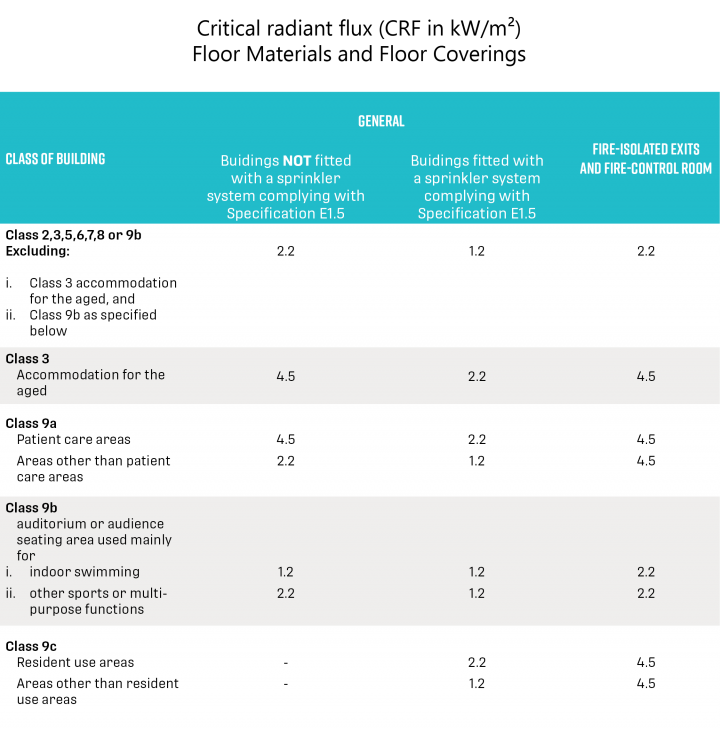

Radiant panel testing also plays an important role within Australia's building code. This refers to the AS ISO 9239-1 with the main difference from the European fire classification being that the heat flux is only reported when the sample is extinguished and not after 30 minutes as in the EU fire classification.

The following regulations apply to carpet in Class 2 to 9 buildings:

Fire protection in rail vehicles

Not only does the radiant panel play a role in the evaluation of building products, the test is also part of the evaluation of the suitability of an indoor floor covering for use in trains. The requirements are set out in EN 45545-2: Rail applications - fire protection in rail vehicles - part 2: requirements for fire behaviour of materials and components.

In EN 45545-2, requirements apply per product group. The following apply to flooring.

Floor composites include the floor substrate (together with any thermal insulation) and floor covering (together with any fixings or adhesives applied in the end us conditions

The more frequently a train passes through tunnels, the higher the requirement (class HL1 to HL3).