The European H2020 BIO4SELF project partners created a bio-based and easy-to-recycle self-reinforced composite material based on PLA fibres with an inherent high stiffness. 2019 has been a whirlwind year for the BIO4SELF project: in March, a prototype car seat shell made of self-reinforced PLA material – an application developed within the scope of the project took an Innovation Award at the JEC World show in Paris. In May, it was awarded a second Innovation Award at the Techtextil technical textiles show in Frankfurt. And in December, BIO4SELF won the prestigious Global Bioplastics.

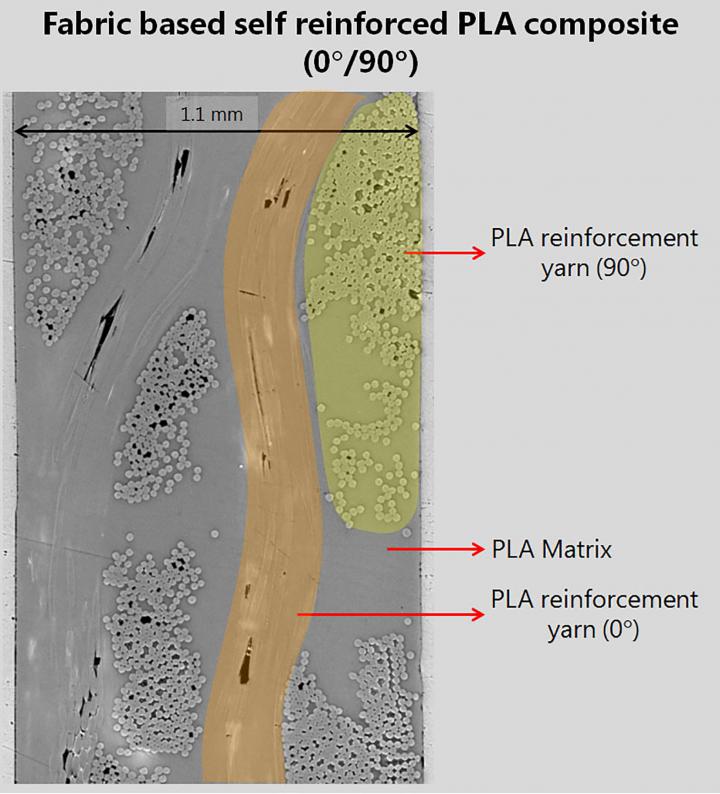

The self-reinforced composite material (SRPC) developed within the scope of the project other partners is composed of two different PLA grades: a low melting temperature PLA grade to form the matrix and an ultra-high stiffness and high melting temperature PLA grade to form the reinforcing fibres. Easily recyclable and industrially biodegradable, the composites are designed for high mechanical strength and rigidity, as well as high temperature and hydrolytic stability, thus upgrading PLA to a material suited for more technical and demanding final applications.

The principle

Two different PLA grades are required to produce self-reinforced polymer composites or SRPCs: a low melting temperature PLA grade to form the matrix and an ultra-high stiffness and high melting temperature PLA grade to form the reinforcing fibres. Bio4self innovations overcome several challenges related to the production of PLA SRPC: formulation of a moisture/humidity-resistant PLA grade; melt extrusion of ultra-high stiffness PLA reinforcement fibres; development of (consolidation and thermoforming) manufacturing procedures to produce the highest performance SRPC material; and industrial scale-up of production.

Main advantages

- Biobased: composites made from two PLA grades with different melting temperatures

- Performance: high mechanical strength, temperature and hydrolytic stability

- Cost: far below carbon fibre composites, comparable to or even below SR-PP

- Upscalable: using commercially-available materials and industrial equipment

- EoL: re-usable, recyclable or industrially compostable as the composite is made of PLA

As a result, the PLA SRPC developed in Bio4self matches the requirements of current commercial self-reinforced polypropylene (PP) composites. Self-reinforced PLA composites made of 0/90 fabric have a stiffness of 4 GPa, which is comparable to the stiffness achieved by self-reinforced PP, but the PLA SRPC has the advantage of using renewable materials with a better end-of-life perspective.