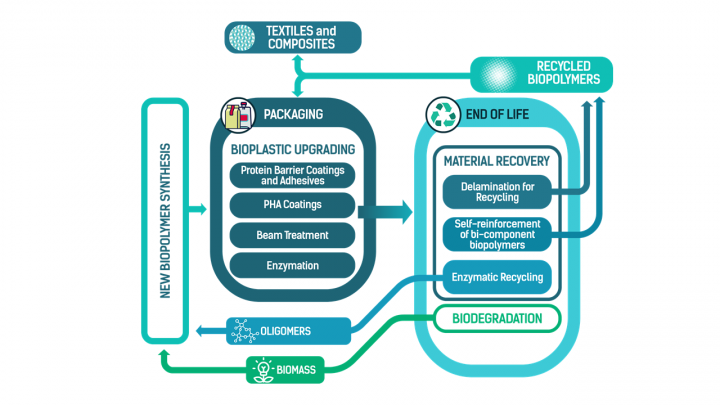

PRESERVE wants to stimulate the circular use of bio-based packaging. To move away from the current situation with predominantly fossil-based materials and limited recycling, we will build on award-winning upcycling strategies from past and current projects. The properties of primary food packaging based on bio-based plastics, paper and board will be improved through bio-based barrier coatings, eBeam irradiation and microfibrillary reinforcement. On the biotechnological side, we will add enzymes in bio-based plastics to stimulate biodegradation, recover functional oligomers and delaminate multilayer packaging to enable recycling.

The production processes to produce at least 10 packaging demonstrators will be scaled up. The improved bio-based packaging will be validated with different types of drinks and food. Biopolymers recovered from the recycling process will be used via the upcycling strategies in value-added applications such as packaging for personal care products and reusable textile or composite carrier bags.

The versatility of the materials (from flexible to rigid packaging), end-of-life options and compatibility with different processes make PRESERVE results relevant for more than 60% of the plastic packaging on the market. The long-term potential will be maximised thanks to the participation of several leading companies in the consortium.

Our 2030 roadmap will provide opportunities to accelerate the emergence of bio-based packaging and create jobs and growth in the sector. To increase the impact of the PRESERVE project we will also conduct consumer studies, a life cycle analysis and safety study, and contribute to standardisation and certification committees.

Objectives

Picture: PRESERVE concept

Although Europe is heavily dependent on fossil-based plastics that it consumes in the order of 50 million tonnes per year, only 32% of the resulting waste is currently recycled and most of it is incinerated or landfilled. In addition, as much as 32% of plastic packaging ends up in the environment, leading to dramatic long-term pollution. As packaging represents more than 40% of the plastics consumed, improving the circularity of these materials has a major impact. Bio-based materials can offer a solution, but drop-in materials do not exist for all applications and furthermore the biodegradability of available biopolymers is not possible in every environment.

PRESERVE will therefore improve bio-based packaging in terms of properties and end-of-life options.

The following strategies will be applied to achieve these goals:

- Improving the gas and oxygen barrier properties

- Separation of layers or labels using removable primers and adhesives.

- PHA coatings that provide barriers against water vapour, beverages and grease. Primarily for beverage packaging based on paper, cardboard and pulp.

- Use of eBeam radiation to improve the barrier and mechanical properties of biopolymers

- Use of self-reinforced bio-based plastics to compensate for degradation of secondary materials during reprocessing. This can be applied to virgin materials but is innovative for processing two-component packs without separating the layers.

- Use of conventional additives such as chain extenders and compatibilizers.

- Use of enzymes in 3 complementary routes

- Combining biopolymers with enzymes to improve biodegradation

- Enzymatic recycling of PLA to obtain high-quality oligomers that can be used as additives or building blocks for new polymers

- Removal of adhesive layers or coatings with enzymatic detergents

Consortium

- IRIS – Spain (coordinator)

- Albstadt-sigmaringen university – Germany

- Centexbel - Belgium

- Aimplas – Spain

- Fraunhofer – Germany

- Itene – Spain

- Next Technology Tecnotessile – Italy

- University of Bologna – Italy

- Biopolis SL – Spain

- Planet Bioplastics SRL – Italy

- BOSTIK SA / Arkema – France

- Carbiolice – France

- Südpack verpackungen GMBH – Germany

- Graphic packaging International – Belgium

- SIBO group – Slovenia

- Beiersdorf AG - Germany

- Organic waste systems NV – Belgium

- Pla.to GMBH – Germany

- ROMEI SRL – Italy

- DenimX B.V. – The Netherlands

- Silon s.r.o. – Czech Republic

- KNEIA SL – Spain

- Crowdhelix Limited – United Kingdom

- European Bioplastics EV – Germany

- Groupe Danone SA – France

- Kraft foods R&D Inc – United States

Acknowledgement

This project has received funding from the European Union's Horizon 2020 research and innovation programme under the European Union's Horizon 2020 research and innovation programme under grant agreement No. 952983