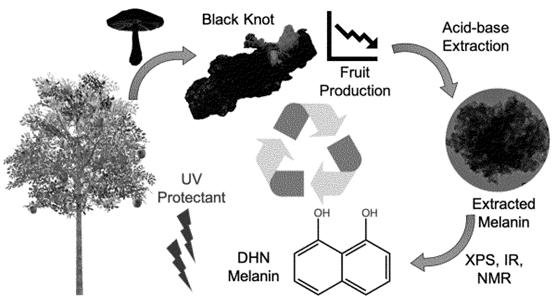

Black knot melanin - a super additive with UV-absorbing and antioxidant properties

Patent number: US20230031761

Publication date: 2023-02-02

Applicant(s): THE UNIVERSITY OF AKRON

Inventor(s): DHINOJWALA ALI, SINGLA SARANSHU, JAIN DHARAMDEEP

Motivation

Polymers, when exposed to factors such as heat, mechanical stress, light, oxygen, chemicals, and water undergo degradation. While formulating polymer-based materials, certain additives are included in the formulation to combat the degradation mechanism occurring during the processing of the formulation or lifetime of the product. These additives are often termed as stabilizers and include light stabilizers, UV absorbers and antioxidants. With the growing focus on sustainability and green environment, great emphasis has been paid on identifying materials that could serve as UV absorbers or antioxidants.

Abstract

The present invention provides a polymer composition, cosmetics, coatings, inks, polymer compounding formulation comprising an all-natural, nitrogen-free black knot fungal (BKF) allomelanin extracted from black knots, which are a fungal growth formed by the Apiosporina morbosa (referred to herein as “BKF melanin” or “BKF allomelanin”). The BKF melanin has been found to be DHN-based nitrogen-free allomelanin. It is naturally sourced and can be economically extracted from what is basically a waste product. Moreover, and quite unexpectedly, BKF melanin has been found to have better UV absorbing and antioxidant properties than synthetic melanin (polydopamine) and commercially available sepia melanin. In some embodiments of the present invention, a small amount of the BKF melanin is uniformly blended into a polymer or similar material to create a composition having excellent UV absorption and antioxidant properties. In some of these embodiments, this composition can be added to various products to provide UV absorption and antioxidant properties. Surprisingly, it has also been found that the UV absorption and antioxidant properties of these polymer compositions can withstand heating and other processing steps associated with polymers, and in particular, rubber without significant reduction in effectiveness.

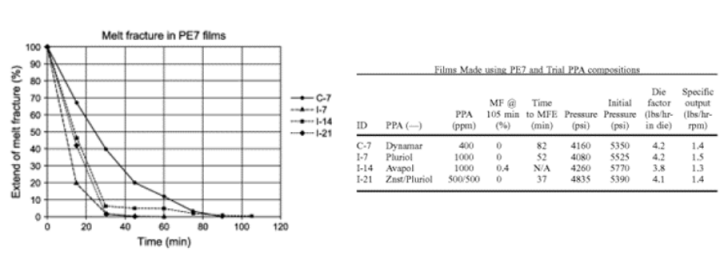

Fluorine-free polymer processing aids including polyethylene glycols

Patent number: US20230036922

Publication date: 2023-02-02

Applicant(s): EXXONMOBIL CHEMICAL PATENTS INC

Inventor(s): LEAF MICHAEL A, VAN HOYWEGHEN DANNY

Motivation

Common additives, particularly for polymers such as polyethylenes intended for use as films, sacks, and other similar articles, include polymer processing aids (PPAs), which help make the pellets easier to manipulate in downstream manufacturing processes (such as extrusion, rolling, blowing, casting, and the like). Adequate amounts of PPA, among other things, help eliminate melt fractures in films made from the polymer pellets. The most common PPAs are or include fluoropolymers (fluorine-containing polymers). It is, however, desired to find alternative PPAs that do not include fluoropolymers and/or fluorine, while maintaining the effectiveness of fluoropolymer-based PPAs in preventing melt fractures.

Abstract

The present disclosure relates to fluorine-free polymer processing aids (PPAs) for polyolefin polymers (such as polyethylene), as well as the polymers themselves, methods of making them, and articles made therefrom. The PPA may contain traces (e.g., 10 ppm or less, preferably 1 ppm or less, such as 0.1 ppm or less) of fluorine, e.g., as an impurity, but well below the amount that would intentionally be included in a polymer composition via such additives (e.g., about 100 ppm of fluorine atoms by mass of polymer product in a typical case where such additives are included). In various embodiments, the polymer compositions can be, e.g., polymer pellets; a polymer melt (as would be formed in an extruder such as a compounding extruder); reactor-grade polymer granules and/or polymer slurries; or other form of polymer composition containing the PPA and optionally one or more other additives. The present inventors have found that polyethylene glycol (PEG) can be an advantageous replacement of fluorine-based PPAs in polyolefin compositions. The PEG-based PPA therefore can comprise between 80 wt % and 100% (on the basis of total mass of the PPA) of the PEG. The PEG can have molecular weight in the range 5,000 to 40,000 g/mol. however, that these lower-molecular-weight PEG compositions can be difficult to handle (e.g., due to relatively lower melting points). Therefore, delivery systems and methods that include the PEG incorporated into a masterbatch make particularly good PEG-based PPA compositions. Therefore, in many embodiments, the PEG-based PPA composition comprises (or consists or consists essentially of) a PEG masterbatch. The PEG masterbatch comprises a carrier resin and one or more PEGs, each PEG having molecular weight less than 40,000 g/mol.

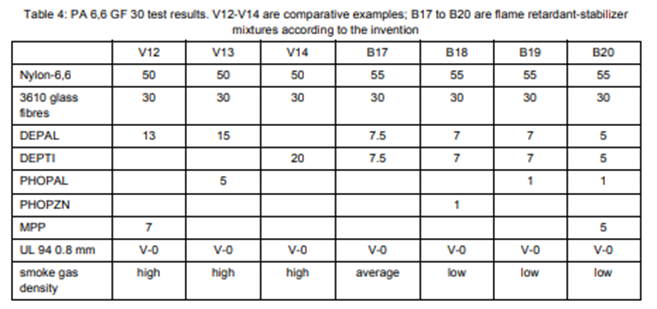

Flame retardant-stabilizer combination for thermoplastic polymers

Patent number: EP4086302

Publication date: 2022-11-09

Applicant(s): CLARIANT INT LTD

Inventor(s): HÖROLD SEBASTIAN, BAUER HARALD, LEUSCHNER EVA MARIA

Motivation

Combustible plastics generally have to be equipped with flame retardants in order to be able to attain the high flame retardancy demands made by the plastics processors and in some cases by the legislator. Preferably - for environmental reasons as well - nonhalogenated flame retardant systems that form only small amounts of smoke gases, if any, are used.

Abstract

The present invention relates to a novel flame retardant combination for halogen-free thermoplastic polymers using titanium-containing phosphinate flame retardants, and to polymeric moulding compounds and mouldings comprising such flame retardant combinations. It has now been found that, surprisingly, titanium phosphinates and titanyl phosphinates, in combination with aluminium phosphinates or zinc phosphinates and optionally with aluminium phosphite or zinc phosphite and further synergists and additives, have particularly good flame-retardant action in thermoplastic polymers and are notable for very low smoke gas density. The present invention therefore provides flame retardant-stabilizer mixtures comprising by weight of aluminium diethylphosphinate and/or zinc diethylphosphinate (5-95%), titanium phosphinates and/or titanyl phosphinates (5-95%), aluminium phosphite or zinc phosphite (0-10%), a nitrogen-containing synergist and/or of a phosphorus-containing and/or nitrogen-containing flame retardant (0-30%), a filler and reinforcer (0-70%), an organic phosphonite and/or an organic phosphite and/or mixtures with phenolic antioxidants (0-3%), an ester and/or salt of long-chain aliphatic carboxylic acids (fatty acids) typically having chain lengths of C14 to C40 (0-3%), where the sum total of the components is always 100% by weight. The polymer more preferably comprises polyamides and/or polyesters.

Coffee grounds as additive for plastics materials

Patent number: DE102021210254

Publication date: 2023-03-16

Applicant(s): BENECKE KALIKO (CONTINENTAL)

Inventor(s): NEUMANN THORSTEN, HECKEL ANDREAS

Motivation

Plastic materials usually contain a number of additives which are necessary to impart certain properties to the material. The additives customarily used are generally based on conventional chemical products or primary raw materials. There is a constantly increasing interest in replacing such conventional additives by sustainable products and/or waste products which are thus to be recycled.

Abstract

The invention relates to the use of sustainable product coffee ground powder as additive in plastics materials without soiling of the plastic materials by the coffee grounds. Indeed, coffee grounds powders can contain 5 to 20% by weight of coffee oils. These coffee oils are soluble in both hydrophilic and hydrophobic media and can be regarded as interfacial mediators. When incorporated into a plastic material, these can also migrate into the polymer matrix and finally emerge at the surface of the plastic material, which is also referred to as exudation. Because of the usually brown color of the carboxyl-containing coffee oil and other anionic components such as organic phosphates, this can lead to soiling of the plastic material, which is usually undesirable and can make the use of coffee grounds impossible in such applications. The inventors have surprisingly found that when coffee grounds are taken up in plastics, Migration of brown coffee oil containing carboxyl groups into the plastics matrix and, in particular, exudation of the coffee oil from the plastics material can be largely or completely prevented by complexing with divalent ions such as Calcium or trivalent ions. As a result, soiling of the plastic materials, for example the plastic layers, can be avoided. The invention thus relates to a plastic material which comprises at least one polymer as matrix, coffee grounds powder containing carboxyl groups and at least one metal compound containing divalent or trivalent metal cation, wherein the molar ratio of carboxyl groups of the coffee grounds powder to the divalent or trivalent metal cations of the at least one metal compound is in the range of 1:0.1 to 1:20.

It has also been found that the coffee grounds powder can not only function as a coloring agent or filler, but the complex or chelate compounds formed from coffee oil and divalent or trivalent metal ions are also suitable, for example, as processing aids and stabilizers. For example, zinc, barium and calcium salts can be used to generate calcium, barium and zinc coffee oils whose structure is very similar to the metal soaps which are usually used, for example, for PVC stabilization.

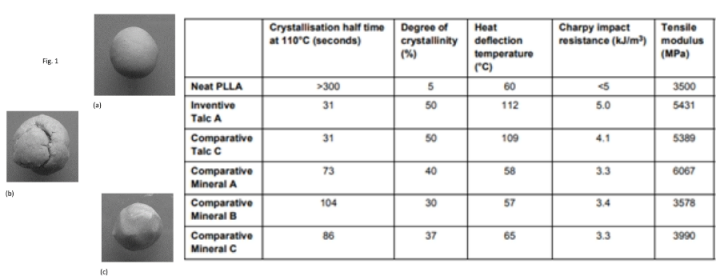

Talc particulates and bioplastic polymers

Patent number: EP4180481

Publication date: 2023-05-17

Applicant(s): IMERTECH

Inventor(s): MELI GILLES, RIJAL BIDUR

Motivation

Increased use of bioplastic polymers, in comparison to fossil fuel-based polymers, is desirable from an environmental perspective. However, some bioplastic polymers can exhibit relatively poor thermomechanical properties (such as impact resistance, tensile modulus, or heat deflection temperature) in comparison to some fossil fuel-based polymers. For example, polylactic acid is known to exhibit low impact resistance, slow crystallization rates and low heat deflection temperature. This has hindered wide-scale use of bioplastic polymers, particularly in applications require high mechanical strength, high temperature resistance and/or high impact resistance.

Abstract

The present invention is directed to polymer compositions comprising a bioplastic polymer and a talc particulate, uses of a talc particulate in polymer compositions comprising a bioplastic polymer, methods of modifying polymer compositions comprising a bioplastic polymer, and articles of manufacture comprising polymer compositions comprising a bioplastic polymer and a talc particulate. Talc particulates have been developed as fillers for polymer compositions. Talc particulate fillers can improve some mechanical properties such as heat deflection temperature and tensile modulus. However, talc particulate fillers typically have a detrimental effect on impact resistance. There is a need to improve the balance of the three properties: impact resistance, heat deflection temperature and tensile modulus, particularly for polymer compositions which comprise one or more bioplastic polymers. The present invention is based on the surprising and advantageous finding that a new talc particulate can improve the properties of polymer compositions comprising a bioplastic polymer such as polylactic acid. The talc particulate is obtained by removing a portion of the largest particles of a high aspect ratio feed talc material. Thus, the talc particulate is a high aspect ratio talc having a relatively low topcut (i.e., d95). This talc particulate has a number of properties that are different to those of the feed talc material and other known talc particulates.

Novel plasticizers, process for the preparation thereof, and use thereof

Patent number: WO2023187302

Publication date: 2023-10-05

Applicant(s): ORPIA INNOVATION, CNRS; UNIVERSITE DE MONTPELLIER; ENSCM

Inventor(s): CAILLOL SYLVAIN, JEGO LUCAS, LAPINTE VINCENT, GARTILI ADÉLAÏDE, BRIOU BENOÎT

Motivation

Plastic materials are predominantly of petroleum origin. In most cases, they are not biodegradable leading to pollution of plastics found in the oceans and problematic management in terms of recycling. Now, consumers are becoming increasingly concerned with ecological and sanitary stakes, and are therefore waiting for environmentally friendly materials, without danger to health.

Abstract

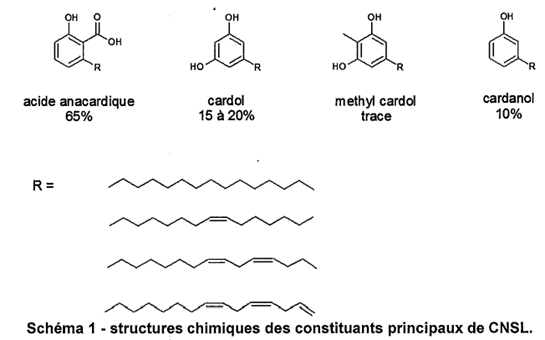

The present invention relates to novel compounds in the field of plastic materials, as plasticizers, in particular cellulose acetate. The invention also relates to a method for preparing such plastic materials. The ideal plasticizer sought should be able to significantly reduce the glass transition temperature (Tg), should be biodegradable, non-volatile and non-toxic, and should migrate slightly over time. In order to obtain effective plasticization, the compatibility between the plasticizer and the polymer is a major factor. In fact, if the plasticizer and the polymer have a high compatibility, this can lead to the establishment of bonds which would lead to a rigidification of the material. However, they must be sufficiently compatible for the plasticizer not to migrate prematurely. In biopolymer-based films, an incompatibility generally appears which is demonstrated by the biopolymer/plasticizer phase separation, presented in the form of drops exuded at the surface of the film. The present inventors use Cashew Nut Shell Oil" or CNSL based compounds as plasticizers for bio-plastics. CNSL is a natural oil derived from cashew nut shells. The main components of the crude CNSL are phenolic compounds: anacardic acid, cardol and cardanol. Methyl cardol is also present, but in trace form. Each of these compounds is itself a mixture of products, substituted with an alkyl or alkenyl chain, said alkenyl chain having 1, 2 or 3 double bonds.

Use of at least one sulfur-containing amino acid for stabilizing recycled thermoplastics, stabilized recycled thermoplastic, stabilizer composition, masterbatch, and molding compound or molded part

Patent number: WO2022243354

Publication date: 2022-11-24

Applicant(s): FRAUNHOFER-GESELLSCHAFT ZUR FÖRDERUNG DER ANGEWANDTEN FORSCHUNG E.V.

Inventor(s): PFAENDNER RUDOLF, MAYER JANNIK, METZSCH-ZILLIGEN ELKE

Motivation

Plastic recyclates are a growing market and an important element in the circulation industry of raw materials, wherein recycled materials should ideally replace new plastics with an identical or at least comparable property profile. Recyclates from the production of plastic parts (so-called post-industrial recyclates) and from collections of used plastics (so-called post-consumer recyclates), however, differ chemically from new plastic products. The structural inhomogeneities of a recycled material influence the plastic properties, such as mechanical properties or morphology. In order to achieve an improvement in the quality of recycled plastics, post-stabilization with selected stabilizers, such as antioxidants, is an essential method.

Abstract

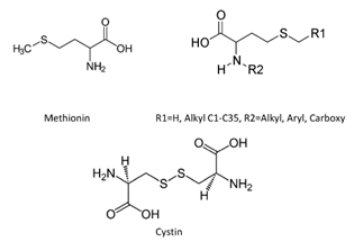

The present invention provides novel stabilizers or stabilizer compositions and novel processes for stabilizing recycled plastics which have a high effectiveness, environmental friendliness and favorable cost structure. The invention relates to the use of at least one sulfur-containing amino acid for stabilizing recycled thermoplastic materials, in particular against oxidative, thermal and/or actinic degradation. Surprisingly, it has been found that the addition of sulfur-containing amino acids is outstandingly suitable in particular for stabilizing thermoplastic recyclates against oxidative, thermal and/or actinic degradation. The stabilizers are inexpensive, environmentally friendly and have a high efficiency. According to a preferred embodiment, the at least one sulfur-containing amino acid is used in a weight ratio of 0.05 to 2.00% by weight, based on the entirety of the thermoplastic recyclates. According to a further preferred embodiment, the at least one sulfur-containing amino acid is selected from the group consisting of methionine or a methionine derivative, cysteine or cystine, and alkali metal, alkaline earth metal, Al or Zn salts thereof, preferably methionine. Very particular preference is given to one thermoplastic being a polyolefin recyclate. In a preferred embodiment, the recyclate compositions comprise, in particular, hindered amines as light stabilizers and long-term heat stabilizers, fillers, acid scavengers, polyol costabilizers or compatibilizers.

Extremely low odor vinylidene substituted aromatic polymer containing composition

Patent number: EP3680287

Publication date: 2020-07-15

Applicant(s): TRINSEO EUROPE GMBH

Inventor(s): CHUNG YAO-CHU

Motivation

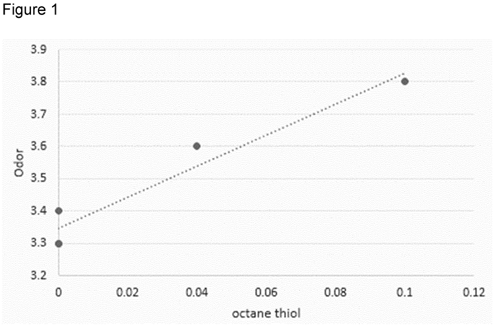

Vinylidene substituted aromatic polymer containing compositions may contain odorous volatile sulfur compounds or may release such volatile sulfur compounds during and after processing at high temperatures, which makes use in an odor sensitive environment such as automotive interior components problematic. There is a need for vinylidene substituted aromatic polymer-based compositions which have or release a low amount of total volatile sulfur compositions, especially when exposed to high temperature environments. There is a need for methods of preparing vinylidene substituted aromatic polymer-based compositions and structures prepared therefrom that do not contain or release volatile sulfur compounds or contain or release small amounts of volatile sulfur compounds.

Abstract

The vinylidene substituted aromatic polymer compositions and articles disclosed herein exhibit lower amounts of volatile sulfur compounds and therefore release lower levels of volatile sulfur containing compounds which can add to the odor emanating from such compositions and structures. Disclosed is a composition comprising: a) one or more polymers containing monomer units derived from vinylidene substituted aromatic monomers; b) one or more antioxidants; and, c) one or more additives of zinc salts, colorants, mold release agents, fillers, reinforcing fibers, ignition resistant additives, stabilizers, adsorbers, antistatic agents, silicon oils, flow enhancers, or combinations thereof; wherein the one or more polymers, antioxidants, and additives do not release volatile sulfur compounds when exposed to temperatures of 200 °C or greater, and according to test procedure VDA 277 release less than 0.02 µC/g of volatile sulfur containing compounds. Disclosed are articles prepared from the compositions disclosed which exhibit the desired levels of volatile sulfur compounds. The volatile sulfur containing compounds may be any sulfur containing compounds having a molecular weight of about 200 g/mole or less. The volatile sulfur containing compounds may be alkyl thiols and the like, such as octyl thiol.