Het Centexbel coating & finishing platform bestaat uit verschillende pilootlijnen waarop we experimenten uitvoeren op het vlak van het wijzigen van de oppervlakte-eigenschappen van textiel en andere flexibele oppervlakken door middel van coating, laminage, veredeling in het kader van industriële prototyping en (collectief en privé) onderzoeksprojecten.

De schaal van de pilootlijnen is geschikt om heel snel prototypes aan te maken met een minimum aan materiaal.

Omdat het platform deel uitmaakt van de volledige Centexbel-VKC organisatie, kunnen alle monsters aan relevante testen worden onderworpen en besproken met ons team van onderzoekers en technologische experts voor verdere verbeteringen en optimalisatie.

Centexbel investeert voortdurend in energie-efficiënte machines en uitrusting om de evoluties in duurzame productie telkens een stap voor te zijn.

Coating

Coating is een techniek waarbij een samengestelde pasta wordt aangebracht op een substraat door middel van een "mes". Coating wordt toegepast om textiel te functionaliseren (voorzien van bijkomende eigenschappen volgens de eindtoepassing) en om complexe en innovatieve materialen te creëren. De samengestelde pasta bestaat doorgaans uit een bindmiddel en functionele additieven.

- eenvoudig en wijdverspreid proces

- aanbrengen van barrière-eigenschappen en/of nieuwe functionaliteiten

- evaluatie van nieuwe bindmiddelsystemen

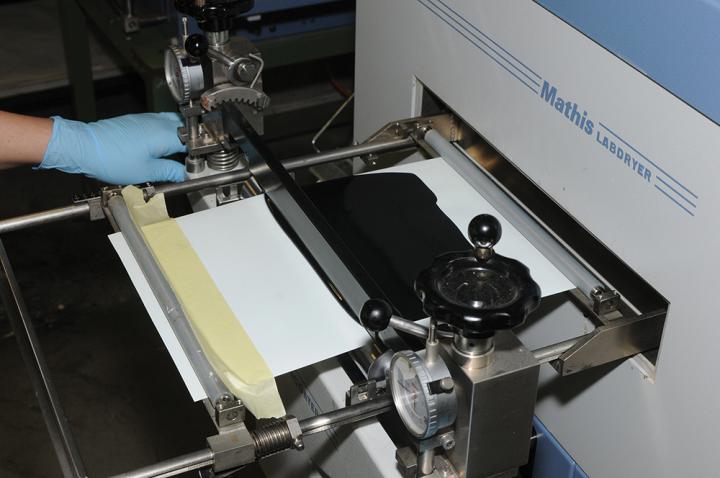

Mathis labdryer - coating

We beschikken o.a. over de volgende technieken om de coatinglaag aan te brengen

- rakel over rol, luchtrakel, transfercoating

- thermisch of IR drogen, UV uitharden

- A4-formaat coaten (Mathis labcoater): water- of solventgebaseerd, 100% (vaste stof) systemen

- roll-to-roll systeem (0.5 m width, Matex): watergebaseerd of 100% systemen

Slot-Die Hotmelt Coating

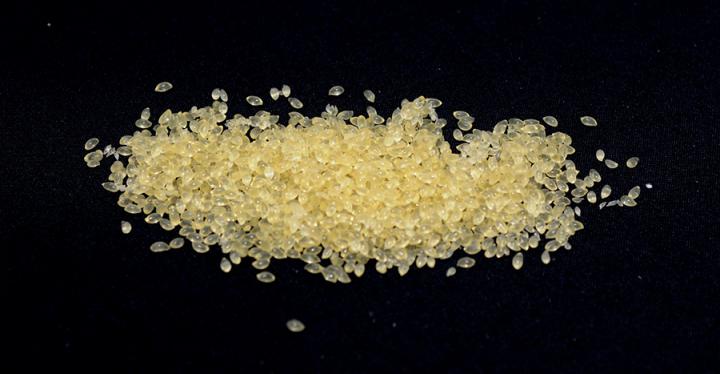

Tijdens het Hotmelt-coatingproces wordt een materiaal in gesmolten vorm in een laag op een substraat aangebracht en vervolgens afgekoeld, waardoor de laag stolt.

Hotmelts worden gesmolten en aangebracht op textiel en andere substraten. Er bestaan twee soorten hotmeltpolymeren: thermoplastische polymeren en reactieve polymeren die vooral verschillen qua uithardingsmethode: thermoplastische polymeren worden uitgehard door afkoeling, terwijl reactieve polymeren een reactie met vb. vocht nodig hebben om uit te harden.

- Thermoplastische polymeren worden vloeibaar (=smelten) in contact met hitte (temperatuur varieert volgens de chemische samenstelling van het polymeer) en worden hard (= vaste vorm) wanneer ze worden afgekoeld. Dit proces is omkeerbaar en kan herhaald worden.

Voorbeelden: PE (polyethyleen) en PP (polypropyleen), EVA (ethyleenvinylacetaat), TPU (thermoplastisch polyurethaan)… - Reactieve polymeren kunnen, eens ze zijn uitgehard, niet opnieuw worden gesmolten omdat de reactie met vb. vocht aanleiding heeft gegeven tot een permanente stolling

Voorbeelden: vocht uithardende PU, vocht uithardende APAO’s (amorfe poly-α-olefines), UV-uithardende acrylaten...

Applicatietechniek voor thermoplastische hotmelt polymeren

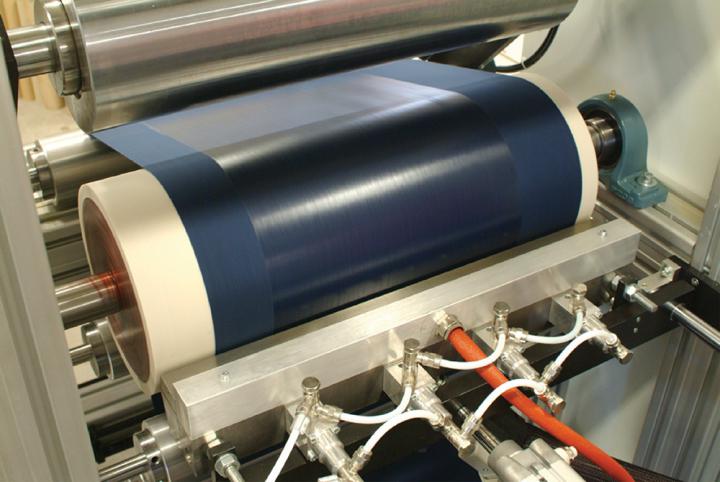

Centexbel beschikt o.a. over een "slot-die" hotmelt coater, waarbij de gesmolten polymeer door een gleufopening op het substraat wordt aangebracht. Het toestel met een werkbreedte van 45 cm is geschikt voor zowel coating- als lamineerproeven.

In principe komen alle flexibele materialen in aanmerking als substraat indien ze van rol tot rol kunnen worden behandeld.

Thermoplastic (biobased) hotmelts

- PO, PES, PA, EVA, PLA, PHBV, PHA zijn plastimeren die opnieuw kunnen worden gesmolten (omkeerbaar proces)en gerecycleerd.

Toepassingen

- thermoplastische hotmelt-polymeren met een opbrengst tussen 2 en 300 g/m² (afhankelijk van de polymeerkarakteristieken).

- gesloten "continue" of open "discontinue" coatinglaag (cfr. behoud ademend karakter) aanbrengen.

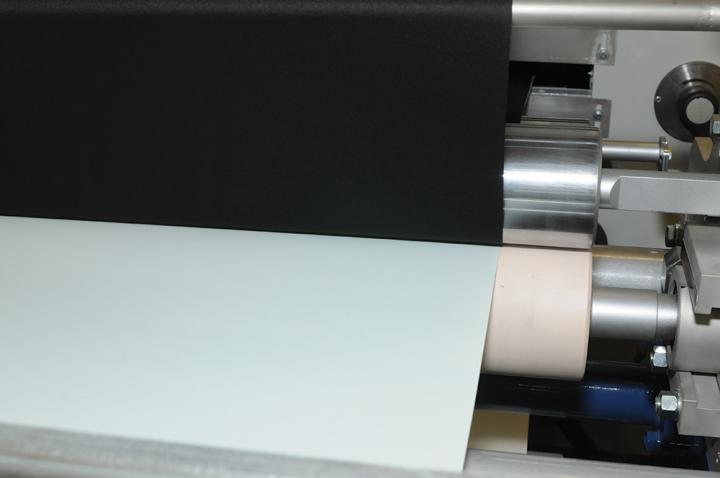

Hotmelt coatingmachine

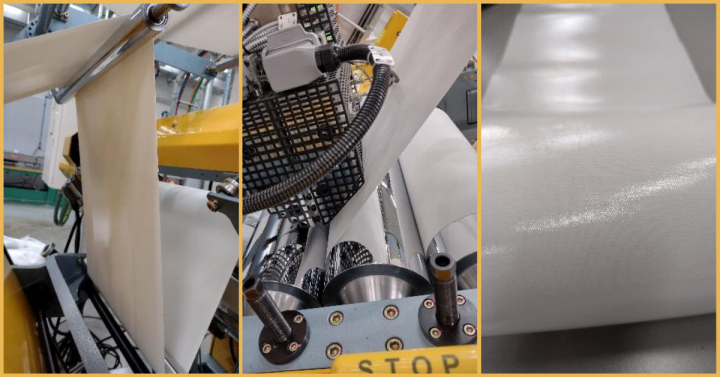

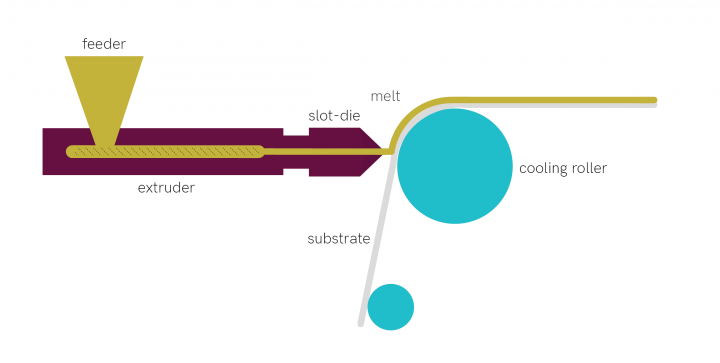

Extrusie-coating

Coaten en lamineren met geëxtrudeerde materialen

Om de bepertke viscositeit van maximum 100 Pas te compenseren die met de hotmelt techniek slechts kan worden verwerkt en om ook courant toegepaste materialen in textiel, zoals PP en PET te kunnen verwerken, hebben we een extrusie-coating pilootlijn geïnstalleerd. Met deze techniek kunnen we materialen met een viscositeit tot 400 Pas of MFI 25 verwerken aan relatief hoge temperaturen.

Horizontaal opgestelde extrusie-coater

Het extrusie-coating proces start bij de planetaire rol extruder (ENTEX), waarin de polymeer pellets opgesmolten en ontlucht worden. Dit systeem resulteert in een uitstekende menging, homogene verwarming en lage wrijving. De smelt wordt met behulp van een pomp gelijkmatig naar de slot-die geleid, waar de coating wordt aangebracht op het substraat. Naast coating kan ook gelamineerd worden. Voor hoog viskeuze materialen kunnen we de coating tijdelijk in gesmolten toestand te houden voor een betere doordringing dankzij het infrarood veld tussen de slot-die en lamineereenheid. Daarnaast verhinderen verschillende koelrollen dat de hitte schade zou toebrengen aan het textielsubstraat.

Procesvoorwaarden

Temperatuur: van 70°C tot 200°C (in 2020 tot 300°C)

Viscositeit: tot 400 Pas of MFI 25

Planetaire rol extruder

- homogene verwarming

- uitstekende menging

- lage afschuifspanning

Coatingbreedte: 40 cm

Subtraatbreedte: tot 50 cm

Coatingdikte: tussen 50µm en 200µm

Mogelijkheid tot lamineren

Minimum hoeveelheid product: 15 kg

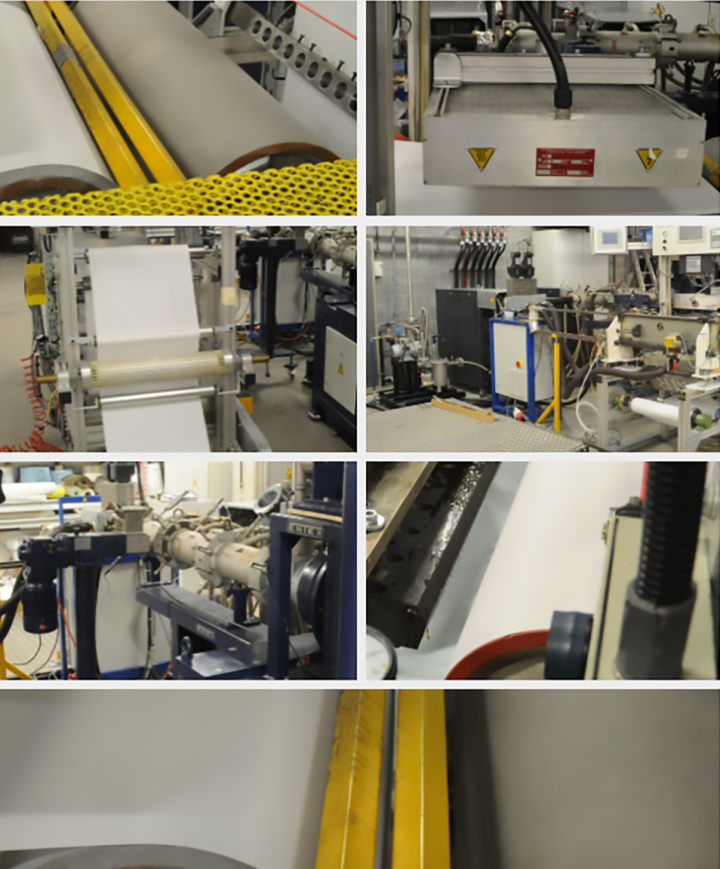

Co-extrusie

Tijdens het co-extrusieproces worden twee of meer materialen door één matrijs geëxtrudeerd, zodat de materialen vóór het afkoelen samensmelten of aan elkaar lassen tot één structuur.

De vlakfilm- of co-extrusielijn van Centexbel-VKC (geïnstalleerd in Kortrijk) is geschikt voor vrijstaande folie-extrusie en laminering op diverse substraten.

- De lijn is uitgerust met drie doseereenheden gekoppeld aan drie enkelschroefsextruders.

- Deze individuele extruders kunnen worden aangesloten op één voedingsblok.

- Door de unieke combinatie van dit voedingsblok kan de polymeermassa van de drie extruders worden verwerkt tot één meerlaagse folie.

- De geëxtrudeerde film kan worden verwerkt als een enkele film of worden gelamineerd op een geselecteerd substraat.

- Het gelamineerde substraat of de geëxtrudeerde film wordt vervolgens gekalanderd met roestvrijstalen koelwalsen en gedroogd bij omgevingscondities voordat hij definitief wordt gewikkeld.

- Op verzoek kan het gelamineerde substraat of de folie op een specifieke maat worden gesneden.

Procesparameters

- Substraatbreedte: ≤ 500 mm

- Breedte van de coating: ≤ 500 mm

- Laagdikte: ≥ 100 µm (tot 10 µm)

- Temperatuur extruder en slot-die: ≤ 450 ºC

- Temperatuur roestvrijstalen rollen: ≤ 200 ºC

- Doseereenheden: tot 3 verschillende polymeren

- Smeltviscositeit: ≤ MFI 25

- Minimum hoeveelheid polymeer: 20 kg

- Minimale substraatgrootte: 200 m

Lamineren

Een gelamineerd textiel bestaat uit twee of meer lagen, waarvan minstens één laag een textiel is. De lagen zijn aan elkaar verlijmd door middel van kleefmiddelen of dankzij de kleefkracht van één of meer lagen waaruit het geheel is samengesteld.

- eenvoudig en wijdverspreid proces

- toepasbaar op verschillende soorten substraat: textiel, films, membraan, folies...

Lamineren van twee lagen

Applicatietechnieken

- productie van A4 proefstukken op Mathis labcoater

- rakel-over-rol toepassingen op Matex semi-industriële lijn (0.5 m)

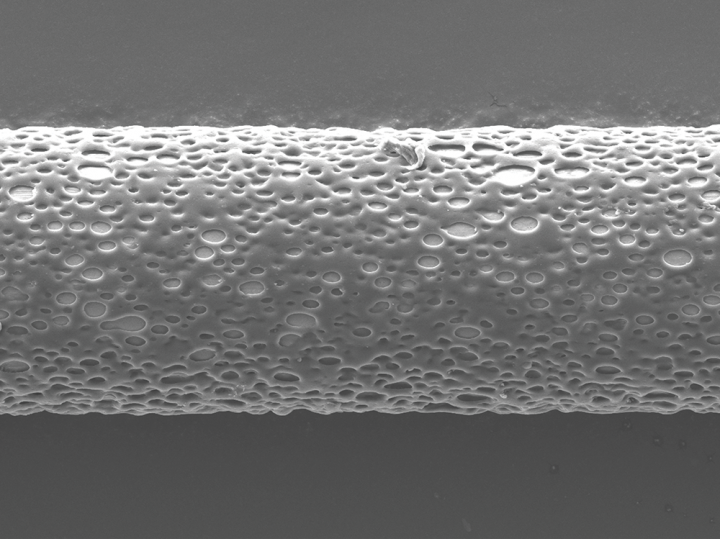

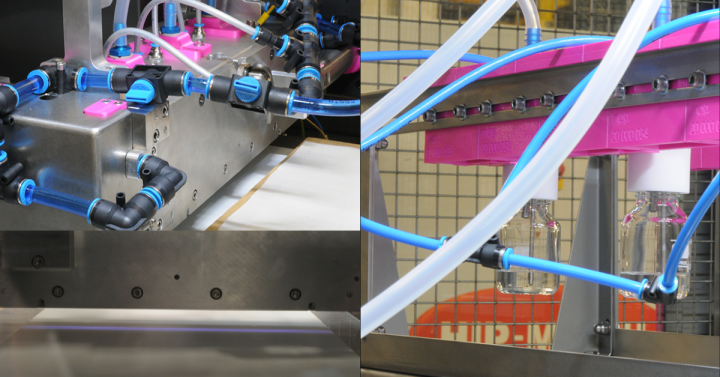

Garencoating

Het Centexbel platform is uitgerust met verschillende modules voor het coaten van garens en multifilamenten, die op een dynamische manier kunnen worden gecombineerd:

- garenspoel

- corona behandeling unit

- UV curing

- IR oven

- conventionele ovens

- dip coating

- dynamische spuitmondsystemen

Om garens optimaal te coaten, hebben de Centexbel onderzoekers toegang tot een uitgebreide reeks van in-house testmethodes om de morfologische, fysische en chemische kenmerken en de parameters van garens en coating formulaties te bepalen.

Door een Cu draad te coaten met geleidende lagen is Centexbel erin geslaagd een draad te creëren die energie opslaat (batterijfunctie) die vervolgens gebreid of geweven kan worden tot weefsels voor gebruik in gebieden zonder toegang tot een energienetwerk.

Digitaal printen

Bij digitale druktechnieken wordt minder inkt gebruikt dan bij conventionele methoden. Zij zijn niet enkel milieuvriendelijker maar laten ook toe om sneller van ontwerp te veranderen.

Centexbel investeerde in een valve-jet digitale printer om te gebruiken in een brede waaier van ontwikkelingen, zoals printen, finishen en verven.

De Chromojet wordt toegepast in onze onderzoeksprojecten naar biologisch afbreekbare verpakkingen

Een van de grootste hindernissen bij de ontwikkeling van biologisch afbreekbare verpakkingen is de beperkte beschikbaarheid van biologisch afbreekbare additieven.

Dit is vooral een probleem wanneer niet-biologisch afbreekbare inkten en kleurstoffen worden aangebracht op verpakkingsfilms die bedoeld zijn voor biologische afbraak. Het CurCol-project ontwikkelt nieuwe biologisch afbreekbare kleurstoffen op basis van "curcumine", een natuurlijke kleurstof. Digitale drukmethodes maken het mogelijk energie-efficiënte drukmethodes te gebruiken.

Textielverven

Gekleurd textiel is het resultaat van een zeer specifiek en accuraat verfproces. Het verven van textiel bestaat uit verschillende - vaak energie en water verbruikende - stappen. Wegens de mileu-impact vereist het verven van textiel een aangepast afvalwaterbeheer.

In-house verfprocessen

- infrarood verfmachine op laboschaal met 16 verfpotten om verschillende formulaties te testen in één doorgang

- haspelverfmachine (textiel van 3m x 0.3m)

- geaccrediteerde in-house testing van kleurechtheden tegen wrijving wassen UV, zweet, enz.

Zeefdruk

Hoewel zeefdruk een algemeen toegepaste techniek is om decoratieve en functionele patronen aan te brengen op textiel, zet Centexbel de flatbed auto-magnetische zeefdruktechniek in voor het creëren van slim textiel en andere high-end producten op basis van geleidende inkten en/of speciale formulaties.

Kenmerken van het flatbed auto-magnetische zeefdruktoestel

- maximale afmetingen: 50 cm x 80 cm

- creatie van decoratieve prints en geleidende tracks voor slim textiel

- direct/indirect printen

- ontwikkelen van inkten voor de creatie van geleidend, functioneel textiel

- inkapseling en integratie van prints op textiel

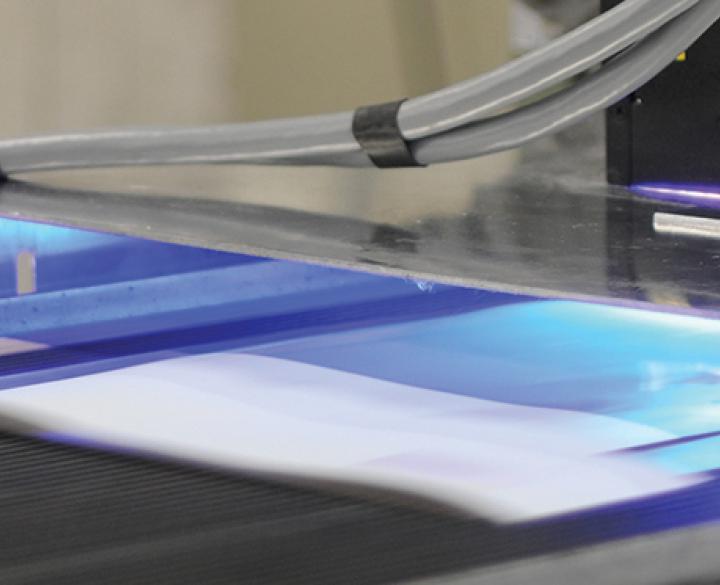

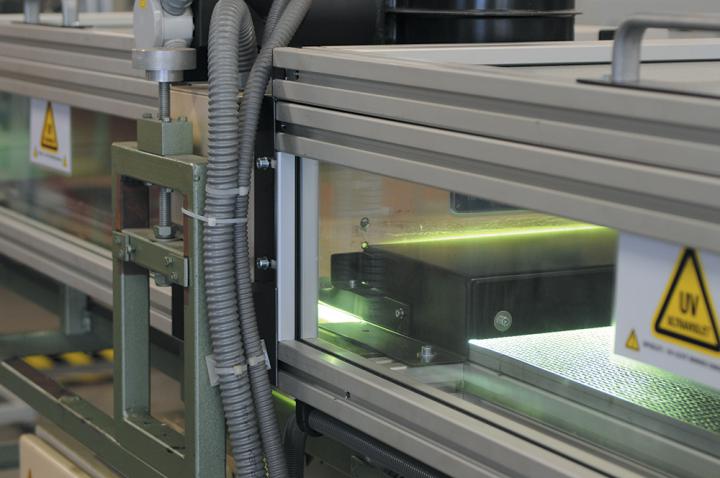

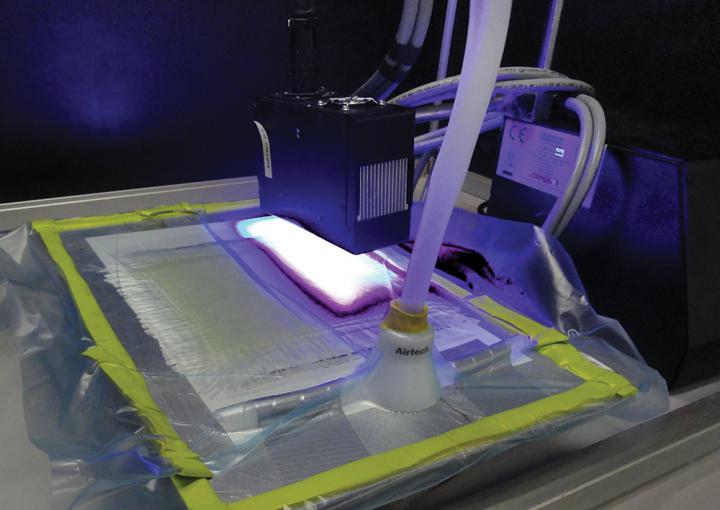

UV en UV-LED curing

UV curing is een snel en milieuvriendelijk proces, dat gebruik maakt van ultraviolet licht om een fotochemische reactie te creëren dat inkten, lijmen en coatings onmiddellijk uithardt.

Toepassingen:

- harde en flexibele substraten

- geschikte techniek voor het aanmaken van prepregs en glasvezelversterkte polymeren

Voordelen

- watergebaseerde of volledig solvent-vrije (100% systemen) formulaties

- milieuvriendelijke technologie voor het uitharden van functionele textielcoatings en -finishes: lage VOC uitstoot en minder waterverbruik

- geschikt voor warmtegevoelige substraten

- snel en laag energieverbruik

- kan op elke bestaande coatinglijn worden geïnstalleerd

- kleine afmetingen

UV-LED curing is een gelijkaardige technologie op basis van monochromatisch in plaats van breedspectrum UV-licht.

Bijkomende voordelen tegenover UV curing

- geen voorverwarming van de lamp (aan-uit)

- geen schadelijk UV-C en UV-B straling

- kwikvrije lamp

- geen ozongeneratie

- geen infraroodstraling (belangrijk voor warmtegevoelige textielsoorten)

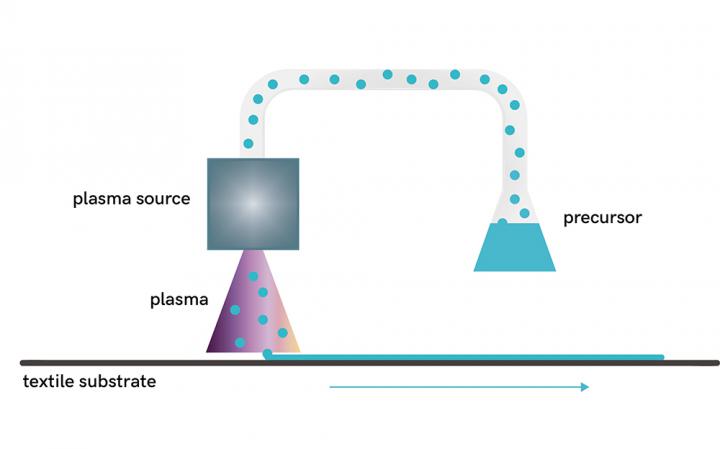

Plasmabehandeling

Het platform is uitgerust met een PlasmaLine van Molecular Plasma Group die een atmosferisch drukplasma genereert in 2 lijnen met een breedte van 30cm.

Dit toestel laat ons toe om het oppervlak van elk materiaal te behandelen en om coatings te deponeren met diktes van enkele 100nm voor een brede waaier van chemische producten/precursoren. De machine is ontworpen voor inline gebruik.

Tijdens een plasmabehandeling wordt een substraat door een plasmazone getransporteerd, die door middel van een krachtbron wordt opgewekt. Deze plasmazone bestaat uit een gasvormig mengsel van energetische en actieve deeltjes (elektronen, ionen, radicalen, fotonen). De plasmabehandeling van een substraat kan worden uitgevoerd zoals het is (plasma-activatie) of door toevoeging van een precursor (plasmapolymerisatie). Het doel van de behandeling is om de oppervlaktechemie van het substraat te veranderen.

Voordelen ten opzichte van traditionele oppervlaktebehandelingstechnieken:

- Het is een droge techniek: geen gebruik van water

- Milieuvriendelijk: geen gebruik van oplosmiddelen

- Wijziging van de oppervlaktechemie zonder wijziging van de bulkeigenschappen (treksterkte, scheurvastheid, flexibiliteit, etc.)

Toepassingen

- Veranderen van de hydrofiliciteit/waterafstotendheid van een oppervlak

- Verbetering van de hechting

- Deponeren van anti-microbiële/ antibacteriële/ antifouling coatings

- Verhogen van de affiniteit met verven en drukken

- Sterilisatie

- Beïnvloeding van de elektrische geleidbaarheid

- Anti-krimpeigenschappen aanbrengen op wol

- Ontsterken van katoen