Objectives

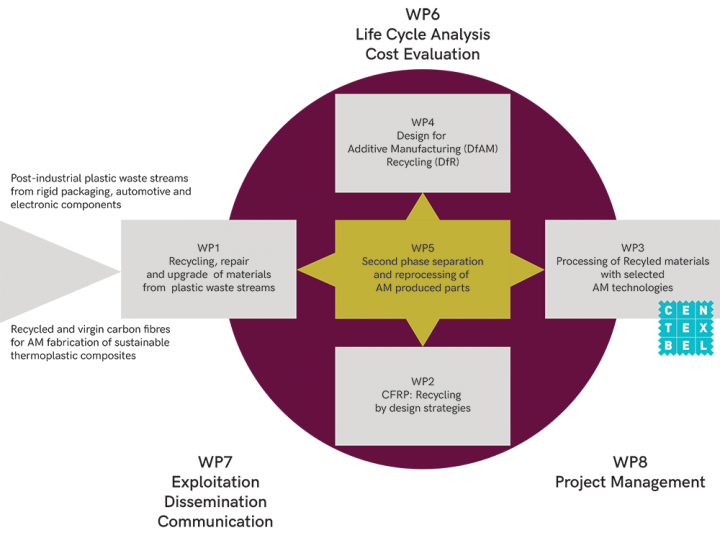

The project aims to develop innovative reclamation and repurposing routes for end-of life plastic and carbon fibre reinforced polymer (CFRP) components by employing advanced nanotechnology solutions, Additive Manufacturing (AM) and recycled resources, for the production of high added value 3D printed products with advanced functionalities.

This way, the combination of AM, polymer processing and recycling technologies could constitute a new paradigm of a distributed recycling process, easily implemented at local scale in collaboration with the industrial sector and collection facilities, in order to create competitive, highly customisable products at lower production costs, in a flexible digital environment that fully unravels the potential of eco design and allows for integration of smart intrinsic self-sensing, self-repairing and recycling options.

The project aims to address all aspects and stages of thermoplastic and CF reinforced thermoplastic 3D printing material development from recycled resources, starting with the selection of suitable waste streams, strategies for material repair, compatibilization and upgrade towards AM processing, compatibility between different thermoplastic matrices and the reinforcing fibres and nanoparticles, comparative assessment of various AM thermoplastic processing technologies and closed-loop material optimisation in terms of processability and performance.

Centexbel's contribution to Repair3D

Centexbel will be in charge of:

- compounding and blending recycled polymers and fibres

- processing these materials into monofilaments for 3D printing

- 3D printing from filaments via Fused Deposition Modelling (FDM) or from pellets by using the Arburg Freeforming technology

- polymer testing and characterisation: rheological behaviour, stability, thermal properties and morphology, mechanical properties, hardness, adhesion of the printed part.

Acknowledgement

This project has received funding from the European Union's Horizon 2020 H2020-NMBP-ST-IND-2018-2020 - Smart plastic materials with intrinsic recycling properties by design (CE-NMBP-26-2018) - under grant agreement No 814588-2

consortium

Project coordinator:

National Technical University (NTUA) of Athens

Partners:

- Warrant Group srl (Italy)

- National Technical University (NTUA) of Athens

- Universiteit Gent (Belgium)

- Fundacio Eurecat (Spain)

- Instituo Tecnologico del Emblaje, Transporte y Logistic (Spain)

- Acondicionamiento Tarrasense Assocacion (Spain)

- Institut de Recherche Technologique Jules Verne (France)

- Sigmatex Ltd (United Kingdom)

- Adamant Aeroiastimikes Efarmoges Etaireia Peioismenis Efthynis (Greece)

- Cambridge Nanomaterials Technology Ltd (United Kingdom)

- Techedge spa (Italy)

- Calzaturificio dal Bello srl (Italy)

- Centexbel (Belgium)

- Maier Scoop (Greece)

- Ilias Koumoulos - Despina Brasinikaoe (Greece)

- Innovation in Research & Engineering Solutions (Belgium)

- Yiotis s.a. - Nutritional Foods Industry (Greece)

- Etaireia Axiopoiiseos Kai Diacheiriseos Tis Periousias tou Ethnikou Metsiviou Polytechneiou (E.M.P.) (Greece)